Photostimulation-responsive nanometer composite fiber and preparation method thereof

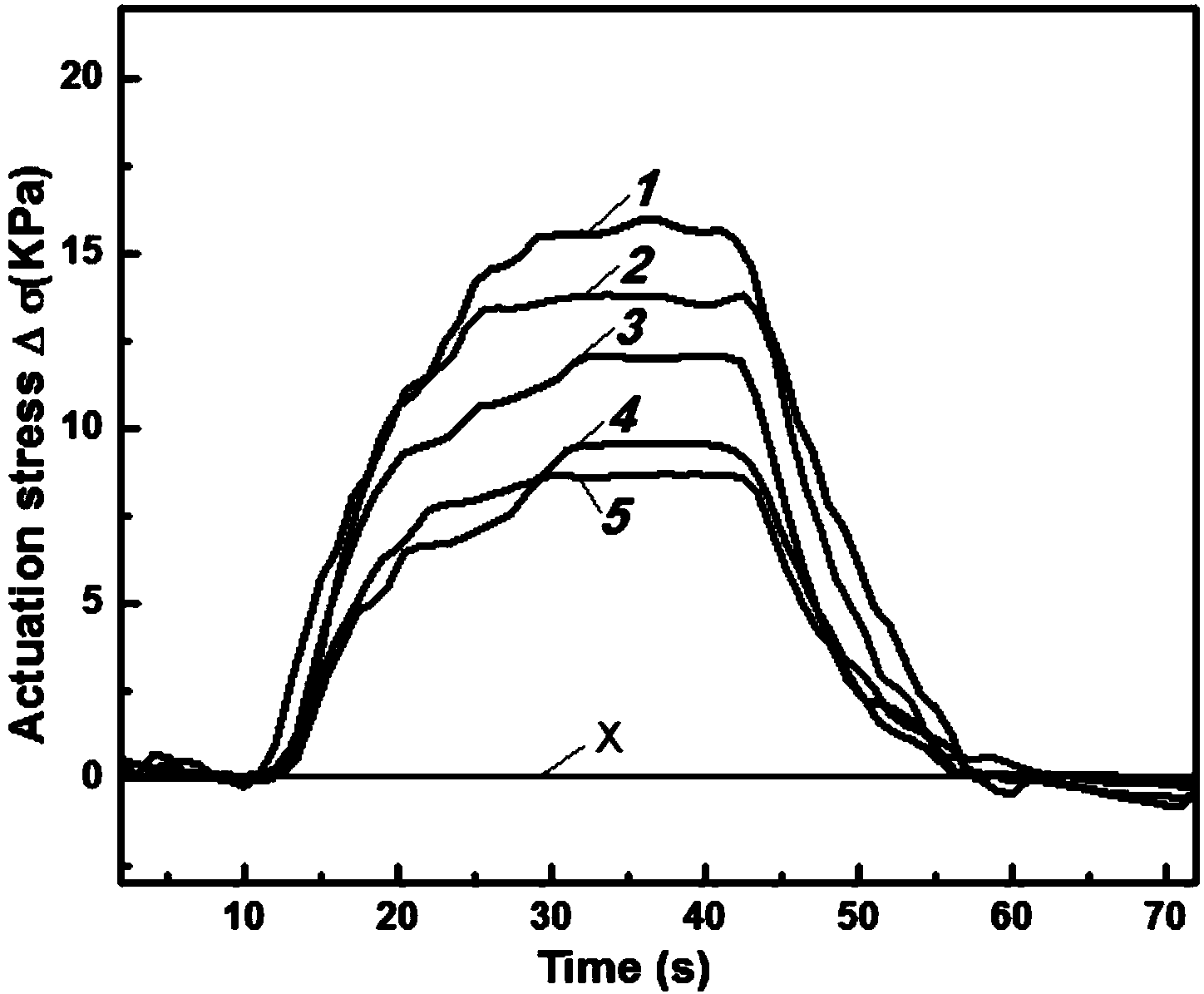

A nano-composite fiber and responsive technology, applied in the direction of fiber chemical characteristics, rayon manufacturing, single-component synthetic polymer rayon, etc., can solve the problems of small output force, cumbersome preparation method, slow response, etc. The effect of dynamic output, simple preparation process, and fast reaction into fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 10 mg of single-walled carbon nanotubes to 20 mL of acetone, and ultrasonicate at room temperature for 1 hour to obtain a black suspension;

[0033] (2) Add 2g of silicone rubber Sylgard-184 liquid component A to the suspension, continue ultrasonic dispersion at 50°C for 1h, then raise the temperature to 75°C and ultrasonically 0.5h to volatilize acetone, add 0.2g of silicone rubber Sylgard after cooling to room temperature -184 liquid component B, stir at room temperature for 30 minutes to obtain a uniform mixture;

[0034] (3) Use a syringe to draw 1mL of the homogeneous mixture, inject it into the simethicone oil preheated to 150°C, immediately observe the formation of black fibers, immerse in the hot silicone oil for 10min to completely solidify, and obtain a single wall containing 0.45wt%. Polysiloxane nanocomposite fibers of carbon nanotubes.

Embodiment 2

[0036] (1) Add 10 mg of multi-walled carbon nanotubes to 20 mL of acetone, and ultrasonicate at room temperature for 1 hour to obtain a black suspension;

[0037] (2) Add 2g of silicone rubber Sylgard-184 liquid component A to the suspension, continue ultrasonic dispersion at 50°C for 1h, then raise the temperature to 75°C and ultrasonically 0.5h to volatilize acetone, add 0.2g of silicone rubber Sylgard after cooling to room temperature -184 liquid component B, stir at room temperature for 30 minutes to obtain a uniform mixture;

[0038] (3) Use a syringe to draw 1mL of the homogeneous mixture, inject it into the simethicone oil preheated to 150°C, immediately observe the formation of black fibers, immerse in the hot silicone oil for 10min to completely solidify, and obtain 0.45wt% multi-walled Polysiloxane nanocomposite fibers of carbon nanotubes.

Embodiment 3

[0040] (1) Add 20 mg of multi-walled carbon nanotubes to 20 mL of acetone, and ultrasonicate at room temperature for 1 hour to obtain a black suspension;

[0041] (2) Add 2g of silicone rubber Sylgard-184 liquid component A to the suspension, continue ultrasonic dispersion at 50°C for 1h, then raise the temperature to 75°C and ultrasonically 0.5h to volatilize acetone, add 0.2g of silicone rubber Sylgard after cooling to room temperature -184 liquid component B, stir at room temperature for 30 minutes to obtain a uniform mixture;

[0042] (3) Use a syringe to draw 1mL of the homogeneous mixture, inject it into simethicone oil preheated to 150°C, immediately observe the formation of black fibers, immerse in hot silicone oil for 10min to completely solidify, and obtain 0.9wt% multiwall Polysiloxane nanocomposite fibers of carbon nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com