Low-carbon comprehensive utilization method of copper slag after smelting reduction

A low-carbon, copper slag technology, applied in the fields of resources and environment, to achieve good effect and promote the effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

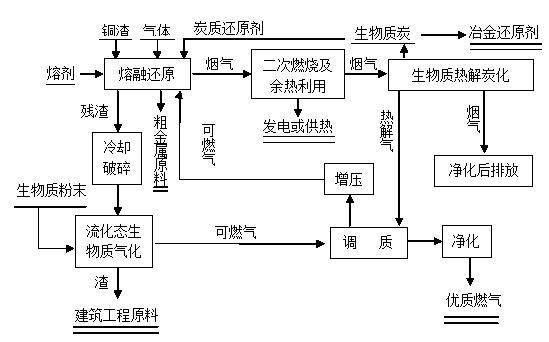

[0027] like figure 1 As shown, the low-carbon comprehensive utilization method after the copper slag smelting reduction, its specific steps are as follows:

[0028] (1) Copper slag smelting reduction method: First, mix copper slag, flux and carbonaceous reducing agent evenly to obtain a mixed material, in which the mass ratio of copper slag to flux is 100:45, and then spray it into a combustible gas with a blowing pressure of 50kPa Replenish the heat source, heat the mixed material to a temperature of 1500°C and fully melt it, and then pass a gas with a blowing pressure of 30kPa for oxidative desulfurization for 10 minutes, then stop the gas supply, and let the molten mixed material go through a reduction reaction for 30 minutes. After the reaction is completed, the obtained Coarse metal raw materials and residues will also produce high-temperature flue gas during this process. The copper slag is the hot slag in the copper smelting process. The copper slag includes the followi...

Embodiment 2

[0038] like figure 1 As shown, the low-carbon comprehensive utilization method after the copper slag smelting reduction, its specific steps are as follows:

[0039] (1) Copper slag smelting reduction method: First, mix copper slag, flux and carbonaceous reducing agent evenly to obtain a mixed material, in which the mass ratio of copper slag to flux is 100:70, and then spray it into a combustible gas with a blowing pressure of 250kPa Replenish the heat source, heat the mixed material to a temperature of 1600°C and fully melt it, and then inject gas with a blowing pressure of 300kPa for oxidative desulfurization for 30 minutes. Coarse metal raw materials and residues will also produce high-temperature flue gas during this process, of which copper slag is water-quenched slag in the copper smelting process, and copper slag includes the following components in mass percentage: FeO55%, Fe 3 o 4 3%, SiO 2 38%, CaO3%, Al 2 o 3 1%, the flux is dolomite, the amount of carbonaceous ...

Embodiment 3

[0049] like figure 1 As shown, the low-carbon comprehensive utilization method after the copper slag smelting reduction, its specific steps are as follows:

[0050] (1) Copper slag smelting reduction method: First, mix copper slag, flux and carbonaceous reducing agent evenly to obtain a mixed material, in which the mass ratio of copper slag to flux is 100:50, and then spray it into a combustible gas with a blowing pressure of 100kPa Replenish the heat source, heat the mixed material to a temperature of 1550°C and fully melt it, and then inject gas with a blowing pressure of 280kPa for oxidative desulfurization for 20 minutes. Coarse metal raw materials and residues will also produce high-temperature flue gas during this process, of which copper slag is hot slag in the copper smelting process, and copper slag includes the following components in mass percentage: FeO40%, Fe 3 o 4 9%, SiO 2 30%, CaO2%, Al 2 o 3 6%, the flux is dolomite, the amount of carbonaceous reducing ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com