Synthetic method of aluminium nitride nanoparticles

A nanoparticle and synthesis method technology, applied in nitrogen compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of aluminum nitride powder purity, crystallinity, particle size, dispersion and morphology specifications, intellectual property monopoly, Complex technology and other problems, to achieve the effect of simple and cheap preparation process, high purity and crystallinity, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Put 25.2g of melamine and 37.5g of aluminum nitrate nonahydrate into a large beaker filled with 500ml of deionized water, then put them into a water bath with a temperature of 97°C and keep stirring to obtain a clear and transparent solution ;

[0025] (2) Cool the clear and transparent solution obtained through the reaction in step (1) to room temperature naturally, then let it stand for 20 hours, and filter the solution to obtain a white intermediate product;

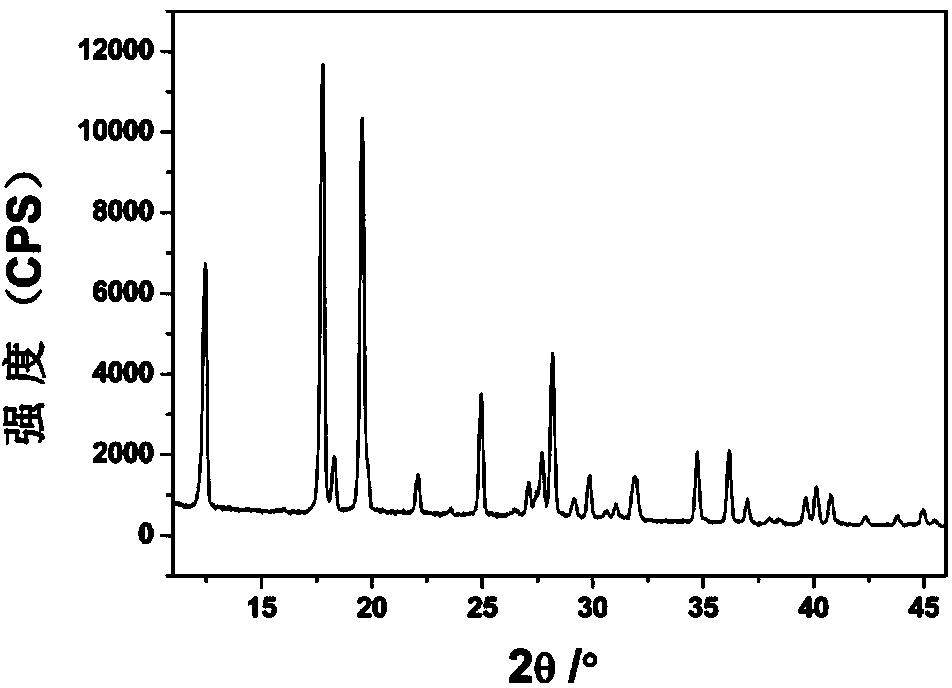

[0026] (3) drying the product obtained in step (2) at 60°C to obtain a white fibrous precursor;

[0027] (4) The precursor obtained in step (3) was reacted in ammonia gas flow (ammonia gas flow rate: 300ml / min) at 1300°C for 2 hours, and naturally cooled to room temperature after the reaction to obtain white aluminum nitride nanoparticle products.

[0028] illustrate:

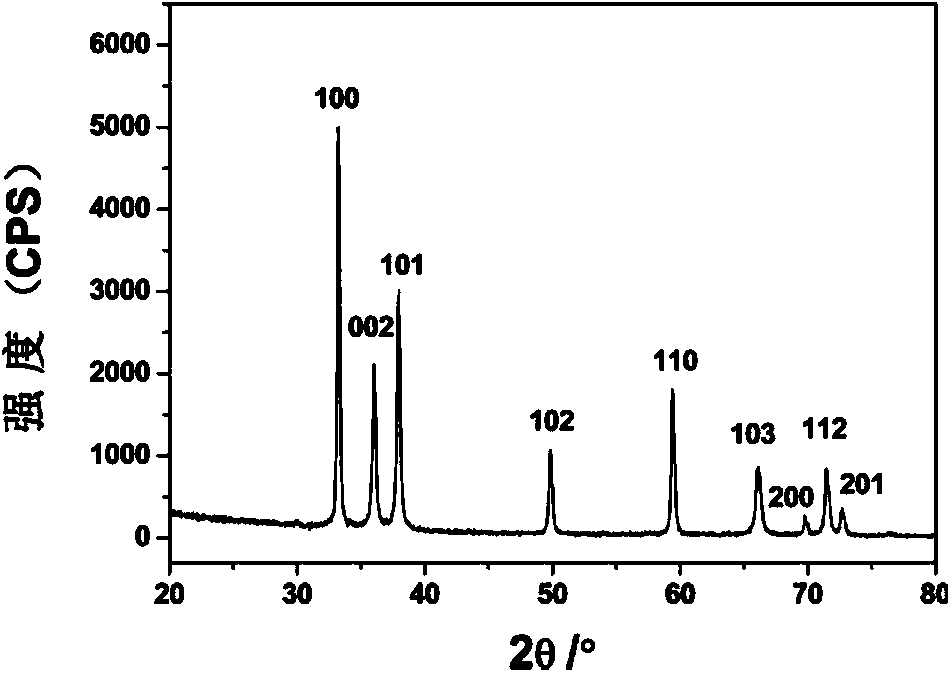

[0029] Such as figure 1 Shown is the XRD pattern (2θ=20-80°) of the as-prepared aluminum nitride product. The diffraction peaks in the ...

Embodiment 2

[0031] Change the consumption of step (1) melamine and aluminum nitrate nonahydrate into 12.6 and 112.5g respectively in embodiment 1 (the molar ratio of melamine and aluminum nitrate nonahydrate is 1:3), and other operations are all the same as in Example 1 Identical, obtain product with embodiment 1.

Embodiment 3

[0033] Change the consumption of step (1) melamine and aluminum nitrate nonahydrate into 12.6 and 225g respectively in embodiment 1 (the molar ratio of melamine and aluminum nitrate nonahydrate is respectively 1:6), the deionized water consumption is changed into 1000 milliliters, other All operations are the same as in Example 1, and the product obtained is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com