Novel marine thermal insulation spiral duct

A spiral air duct, a new type of technology, is applied in the direction of heat insulation protection pipes, pipes, rigid pipes, etc., which can solve the problems of insufficient mechanical strength, poor air duct strength, energy consumption, etc., and achieve strong steam penetration resistance and overall size The effect of stability and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

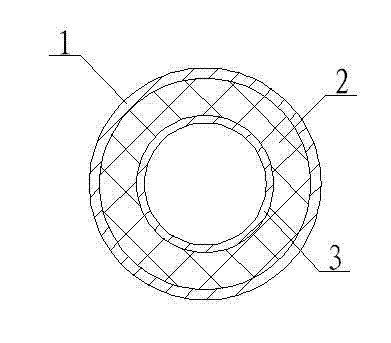

[0016] figure 1 As shown, a new type of marine thermal insulation spiral air duct includes an outer tube layer 1, an intermediate thermal insulation tube 2 and an inner tube 3, the outer tube 1, the intermediate thermal insulation tube 2 and the inner tube 3 are coaxially socketed from the outside to the inside in sequence, and the middle insulation tube Pipe 2 is a modified phenolic resin foam insulation layer, the thickness of the middle insulation pipe is 20-80mm, the outer pipe 1 is galvanized steel pipe or stainless steel pipe or color steel pipe, the thickness of the outer pipe is 0.1-0.5mm, and the inner pipe 3 is galvanized Steel pipe or stainless steel pipe or colored steel pipe or aluminum pipe, the thickness of the inner pipe is 0.05~0.5mm.

[0017] When preparing the novel thermal insulation spiral air duct for ships of the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com