Method for preparing thin films made of lead zirconate titanate

A technology of lead zirconate titanate and film, applied in the field of film made of lead zirconate titanate, which can solve the problems of low film productivity, low economic viability, and low film preparation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

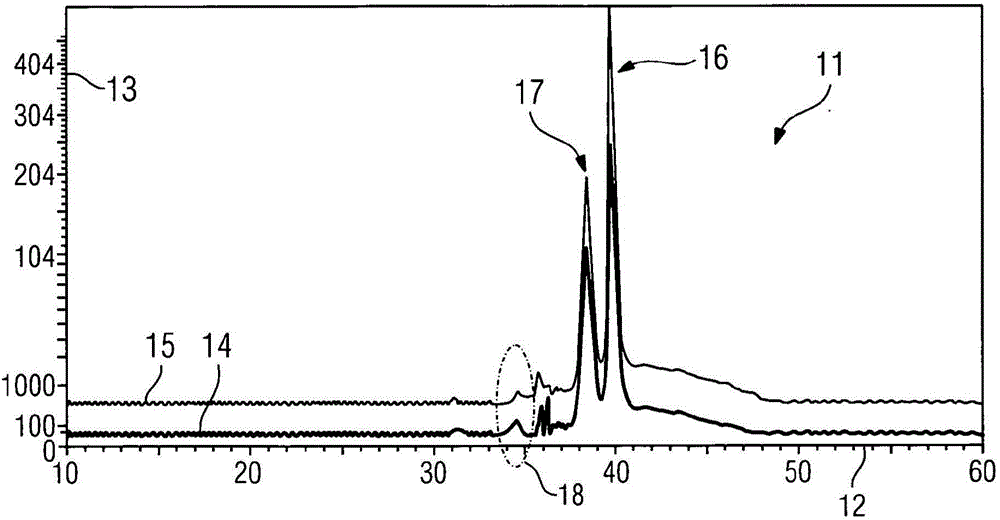

[0027] image 3 An X-ray diffraction pattern 11 of lead zirconate titanate prepared according to a conventional sputtering method is shown. The X-ray diffraction pattern 11 has an abscissa 12 along which the diffraction angle is indicated, and an ordinate 13 along which the amplitude is indicated. The thin film is applied to a substrate, which is a silicon wafer.

[0028]The first curve 14 and the second curve 15 respectively show the spectra of lead zirconate titanate in the film. The films were applied to the substrate using a conventional sputtering method, where the substrate temperature was 500°C for the first curve 14 and 550°C for the second curve 15 . Both films were prepared using a combined deposition rate of 5 nm / min for Pb, Zr, and Ti, with pyroelectric coefficients of approximately 2·10 -4 C / m 2 .

[0029] In both curves 14 and 15 a prominent peak 16 is shown for platinum and a prominent peak 17 for lead zirconate titanate in a perovskite structure in 111 ori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com