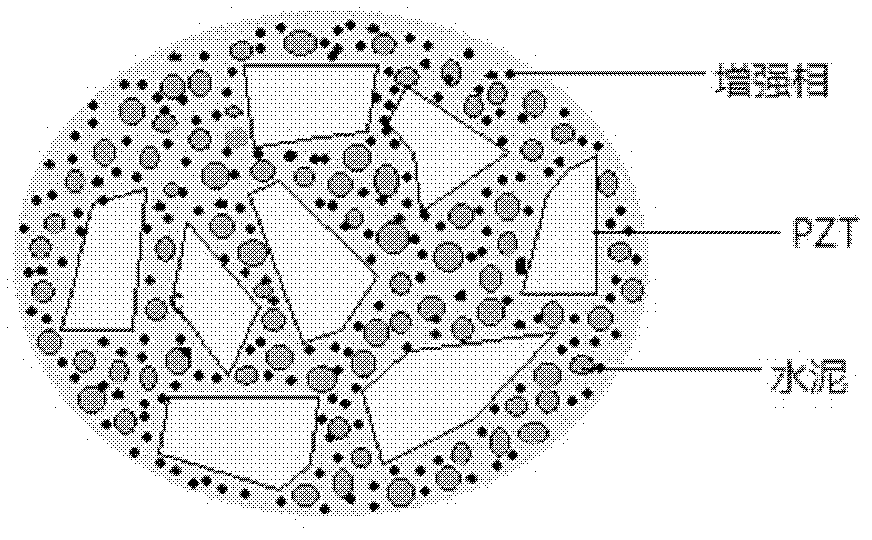

High-efficiency cement-based piezoelectric material and synthesizing method thereof

A piezoelectric material, cement-based technology, applied in the field of piezoelectric materials, can solve the problems of easy generation of false signals, low sensitivity, low piezoelectric performance, etc., to improve polarization efficiency and piezoelectric performance, improve dielectric constant and Densification, the effect of reducing the intensity of the external electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

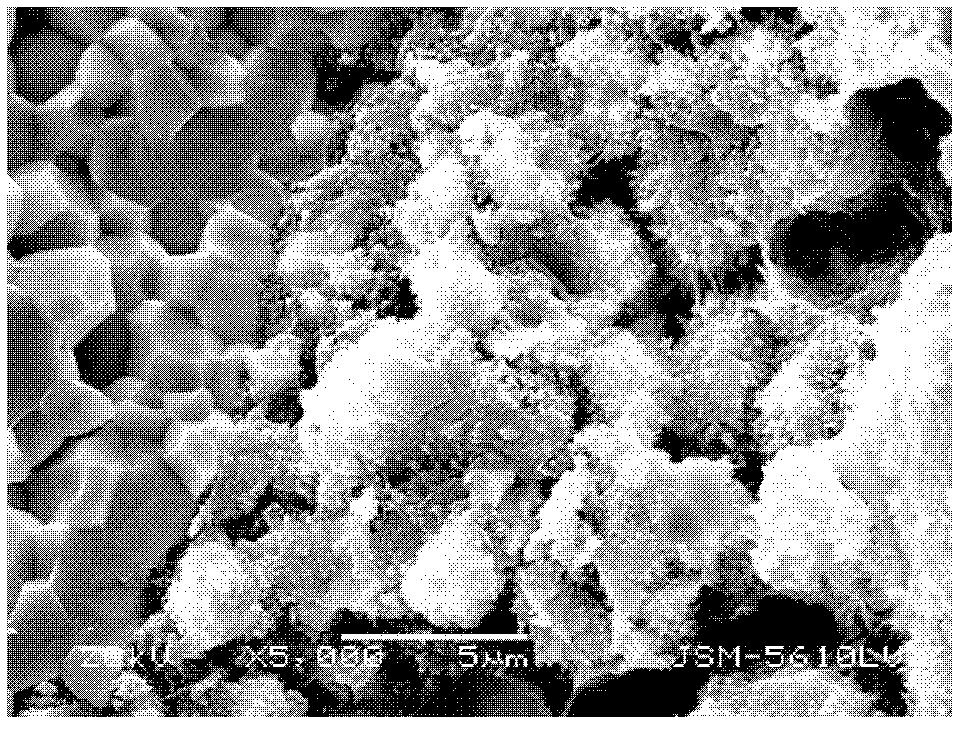

[0026] Take lead zirconate titanate (PZT) ceramic particles, ordinary portland cement (grade 52.5) and silica fume of the reinforcing phase according to the proportions in Table 1, and use absolute ethanol as the medium, ball mill and mix for 15 minutes, dry, pass through 0.2mm Sieve and set aside. Then according to the water-binder ratio (the weight of water: the total weight of cement and reinforcing phase) is 0.2, add water and a polycarboxylate superplasticizer with a water reducing rate of 20%, and the addition of the superplasticizer is cement. 2%, stir evenly and press it into a 20mm×2mm disc. First, 20°C, 95% RH standard curing for 2 days, then 90°C, 100% RH, heat curing for 3 days, and finally scrub the surface with acetone, and then spread evenly on both sides of the disc. Coat the non-fired silver paste, bake in a drying oven at 80°C for 2 hours until dry, and then polarize in silicone oil at 100°C for 30 minutes, with a polarization electric field strength of 1.5...

Embodiment 9-12

[0057] Lead zirconate titanate (PZT) ceramic particles with a particle size of 70-200 μm, a piezoelectric strain constant of 374 pC / N, and a dielectric constant of 1700, ordinary Portland cement (grade 52.5) and SiO 2 Reinforced phase quartz sand with a content of more than 90% and a particle size of 0.1-150 μm is taken according to the ratio in Table 7, mixed with absolute ethanol by ball milling, dried, and sieved through a 0.2 mm sieve for use. Then add water and a polycarboxylate superplasticizer with a water reducing rate of 20% according to the set water-binder ratio (weight of water: total weight of cement and reinforcing phase) and the amount of high-efficiency water-reducing agent, mix well and then press Formed into a 20mm×2mm disc, first 20°C, 95% RH standard curing for 2 days, then 90°C, 100% RH, heat curing for 3 days, finally scrub the surface with acetone, and then evenly coat the non-burning silver paste on both sides of the disc, Bake in a drying oven at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Piezoelectric strain constant | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Piezoelectric strain constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com