Production method of pseudorabies virus vaccine

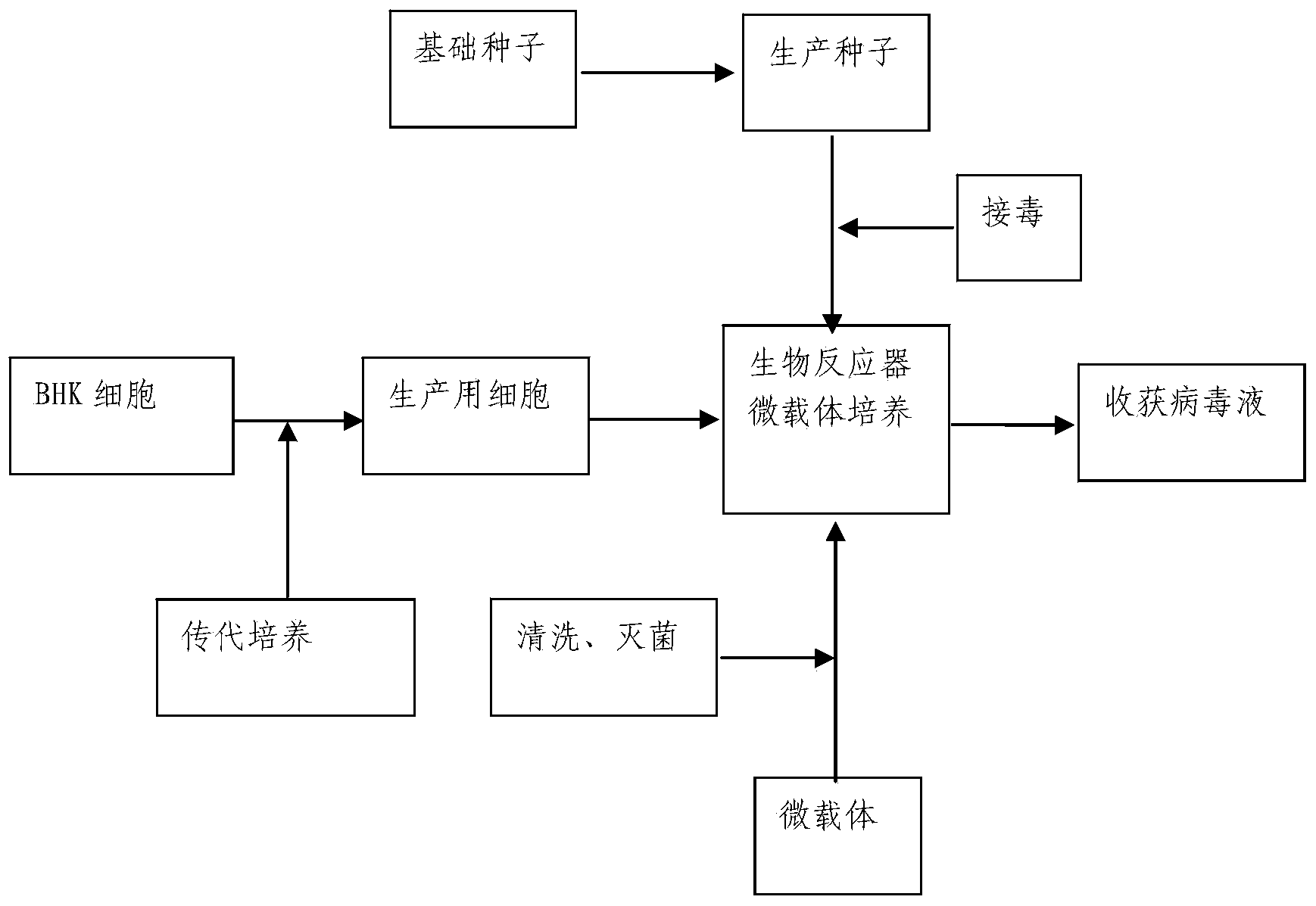

A pseudorabies virus and production method technology, which is applied to the production field of pseudorabies virus vaccine, can solve the problems such as hidden quality risks, high production cost and high labor intensity of the vaccine, and achieve simple and stable production process, balanced and stable quality, and a degree of automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: (1) Passaging and culturing of cells for seedling production: The suckling hamster kidney (BHK-21) cell line was selected as the cells for seedling production. Take well-grown BHK-21 cells in cell culture flasks, digest and passage them with EDTA-trypsin cell dispersion solution (Hank's solution containing 0.25% trypsin (1:250), 0.02% EDTA), and replace with cell growth solution (containing 90 %DMEM solution, 10% bovine serum, 200 units / ml of penicillin sodium and streptomycin sulfate each, pH 7.4) continue to culture in cell culture flasks, culture temperature is 37 ℃, when a dense and good cell monolayer is formed, use Carry out microcarrier suspension culture in continuous subculture or inoculation in bioreactor, wherein the bioreactor is a bioreactor suitable for microcarrier suspension culture that can automatically control temperature, pH, dissolved oxygen and stirring speed parameters;

[0027] (2) Propagation of virus seeds for seedling production: Di...

Embodiment 2

[0034]Example 2: (1) Passage and culture of cells for seedling production: the porcine kidney (PK-15) cell line was selected as the cells for seedling production. Take well-grown PK-15 cells in cell culture flasks, digest and passage them with EDTA-trypsin cell dispersion solution (Hank's solution containing 0.25% trypsin (1:250), 0.02% EDTA), and replace with cell growth solution (containing 98 %DMEM solution, 2% bovine serum, 250 units / ml of penicillin sodium and streptomycin sulfate each, pH 7.0) continue to culture in cell culture flasks, culture temperature is 37 ℃, when a good cell monolayer is formed, use Continue to subculture or inoculate in a bioreactor for microcarrier suspension culture, wherein the bioreactor is a bioreactor suitable for microcarrier suspension culture that can automatically control temperature, pH, dissolved oxygen and stirring speed parameters;

[0035] (2) Propagation of virus seeds for seedling production: Dilute virus seeds 10 times with cell...

Embodiment 3

[0042] Example 3: (1) Passaging and culturing of cells for seedling production: the monkey kidney (Marc-145) cell line was selected as the cells for seedling production. Marc-145 cells growing well in the cell culture flask were digested and passaged with EDTA-trypsin cell dispersion solution (Hank's solution containing 0.25% trypsin (1:250), 0.02% EDTA), and cell growth solution (containing 94 %DMEM solution, 6% bovine serum, 100 units / ml of penicillin sodium and streptomycin sulfate each, pH 6.8) continue to culture in the cell culture flask, the culture temperature is 37 ℃, when a good cell monolayer is formed, use Continue to subculture or inoculate in a bioreactor for microcarrier suspension culture, wherein the bioreactor is a bioreactor suitable for microcarrier suspension culture that can automatically control temperature, pH, dissolved oxygen and stirring speed parameters;

[0043] (2) Propagation of virus seeds for seedling production: Dilute virus seeds 10 times wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com