Bonded silica gel stationary phase with multi-acting-force mixed modes as well as preparation method and application thereof

A bonded silica gel, mixed-mode technology, applied in the field of chromatographic separation, can solve the problems of weak hydrophobicity, lack of aromatic selectivity, weak hydrophobicity, etc., and achieve the effects of low preparation cost, wide application of preparation methods, and high bonding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

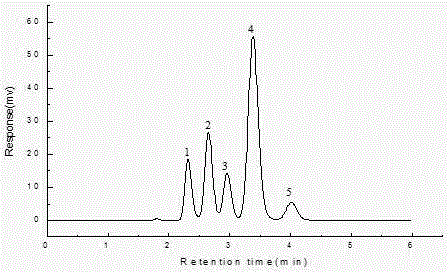

Embodiment 1

[0038] Add 4.0 g of chloropropyltriethoxysilyl silica gel into a round bottom flask, add dropwise 1.0 mL of N-octylbenzimidazole and 60 mL of freshly evaporated dry 1,4-dioxane, and reflux at 110°C Stir for 48 h, filter after cooling, and wash the filtered solid with toluene, ethanol-water solution with a ratio of 1:1, water, and methanol three times in sequence, and finally vacuum-dry at 60°C for 8 h to obtain N-octyl Benzimidazole ionic liquid stationary phase. The structure of the stationary phase is:

Embodiment 2

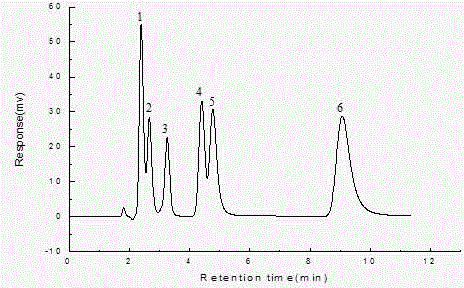

[0040] Add 4.0 g of chloropropyltriethoxysilyl silica gel into a round-bottomed flask, drop into 1.0 mL of N-octadecylbenzimidazole and 60 mL of freshly evaporated dry 1,4-dioxane, at 110°C Reflux and stir for 48 h, filter after cooling, and wash the solid obtained by filtration with toluene, ethanol-water solution with a ratio of 1:1, water, and methanol three times in sequence, and finally vacuum-dry at 60 °C for 8 h to obtain N-octadeca Alkyl benzimidazole ionic liquid stationary phase. The structure of the stationary phase is:

[0041] The stationary phases of Examples 1 and 2 were repeatedly and alternately washed for four months in the range of mobile phase pH=3-9, and the chromatographic column efficiency dropped by about 5%, and the RSD (n=6) of the biphenyl retention time change < 2% , which shows that under the conditions of neutrality, weak acidity and weak alkalinity, the chemical properties of the bonded stationary phase of the present invention are relatively st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com