Preparation method of Pt-C (platinum-carbon) catalyst for nitrobenzene hydrogenation

A catalyst, a technology for nitrobenzene, which is applied in the reaction field of hydrogenation reduction of nitrobenzene to generate p-aminophenol, can solve the problems of catalyst poisoning, low catalyst activity, etc., and achieves improved adsorption capacity, high catalytic activity and strong Coulomb effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

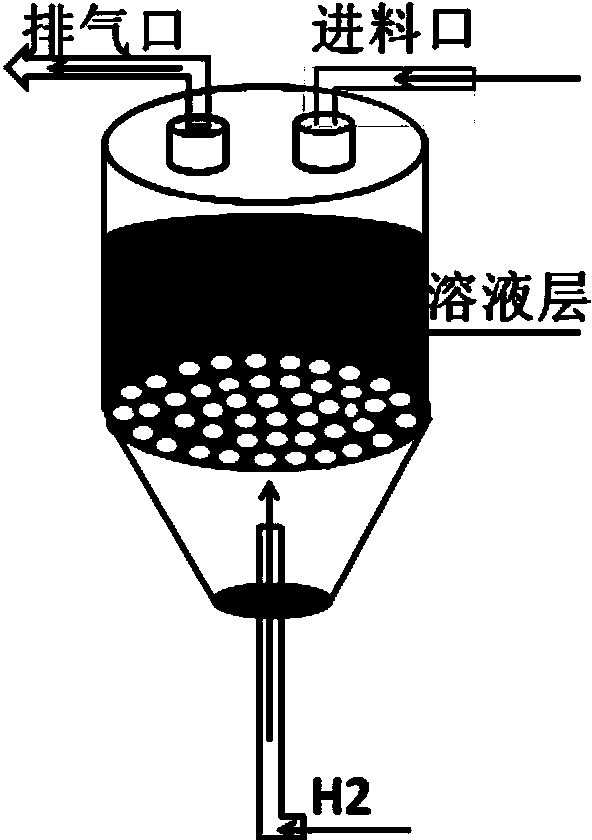

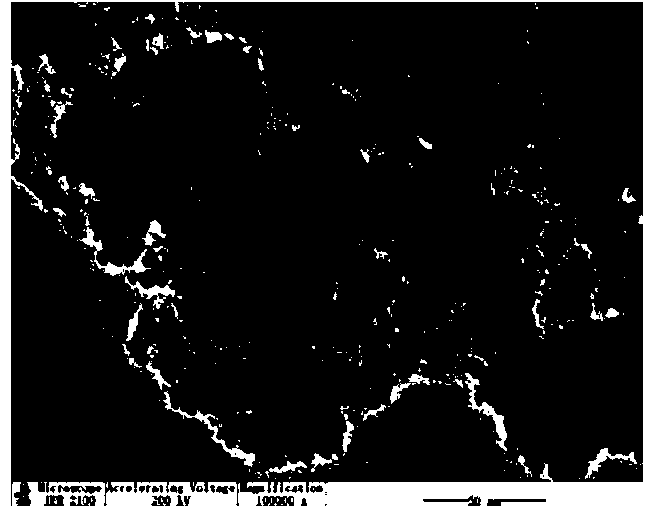

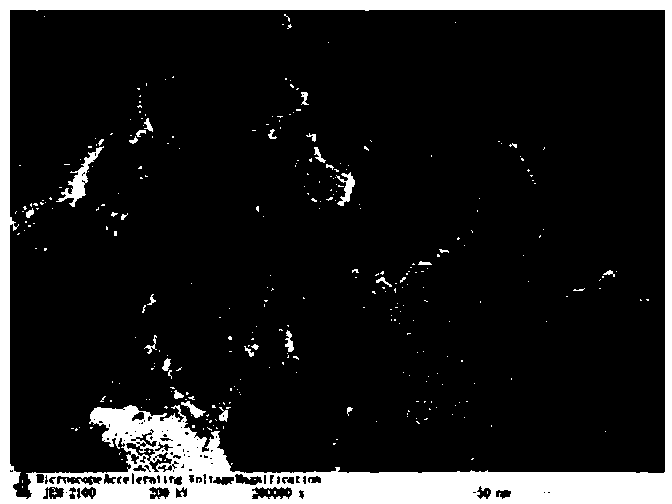

[0017] Example 1: Accurately weigh 5 kg of modified activated carbon, add 50 L of distilled water, and stir for 3 hours to obtain suspension A of activated carbon. At the same time, the prepared ethanolamine hydroxyplatinum containing 0.100 kg of Pt was dissolved in 1 L aqueous solution containing 0.365 kg of sodium dodecylbenzenesulfonate, and stirred for about 5 hours to completely disperse the platinum precursor to obtain solution B. Then, pass hydrogen gas into solution B through an aeration device similar to a sand core funnel and control the gas intake rate to 50-60ml / min for about 10 minutes. At this time, the color of the solution is dark brown, and the aeration is stopped to obtain hydrosol C. Add A to the C system, stir for about 24 hours, so that the active component Pt is completely adsorbed on the surface of the carrier in the form of particles and ions; then use a micro peristaltic pump to dissolve 0.255kg Sodium borohydride solution (according to the mass ratio ...

example 2

[0018] Example 2: Accurately weigh 5 kg of modified activated carbon, add 50 L of distilled water, and stir for 3 hours to obtain suspension A of activated carbon. At the same time, the prepared ethanolamine hydroxyplatinum containing 0.150 kg of Pt was dissolved in 1 L aqueous solution containing 0.554 kg of sodium dodecylbenzenesulfonate, and stirred for about 5 hours to completely disperse the platinum precursor to obtain solution B. Then, through an aeration device similar to a sand core funnel, inject hydrogen into B and control the intake rate to 50-60ml / min for about 10 minutes. At this time, the color of the solution is dark brown, stop the aeration to obtain hydrosol C; add A to C In the system, stirring for about 24h, the active component Pt is completely adsorbed on the surface of the carrier in the form of particles and ions, and then the 0.388kg sodium borohydride solution ( According to the mass ratio of ethanolamine hydroxyplatinum: sodium hydroxide = 1:1.5, add...

example 3

[0019] Example 3: Accurately weigh 5 kg of modified activated carbon, add 50 L of distilled water, and stir for 3 hours to obtain suspension A of activated carbon. At the same time, the prepared ethanolamine hydroxyplatinum containing 0.200kg of Pt was dissolved in 1L aqueous solution containing 0.743kg of sodium dodecylbenzenesulfonate, and stirred for about 5 hours to completely disperse the platinum precursor to obtain solution B. Then, pass hydrogen into solution B through an aeration device similar to a sand core funnel and control the gas intake rate to 50-60ml / min for about 10 minutes. At this time, the color of the solution is dark brown, stop the aeration to obtain hydrosol C; add A to In system C, stir for about 24 hours, so that the active component Pt is completely adsorbed on the surface of the carrier in the form of particles and ions, and then use a micro peristaltic pump to dissolve 0.520kg of sodium borohydride solution in 1L of water at a flow rate of 10ml / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com