Method for producing barium sulfate from combination-process industrial ammonium chloride solid waste

A technology of solid waste and barium sulfate, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of waste of barium resources, polluted surface water, environmental pollution, etc., and achieves the effect of eliminating the hidden danger of environmental pollution and improving the economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

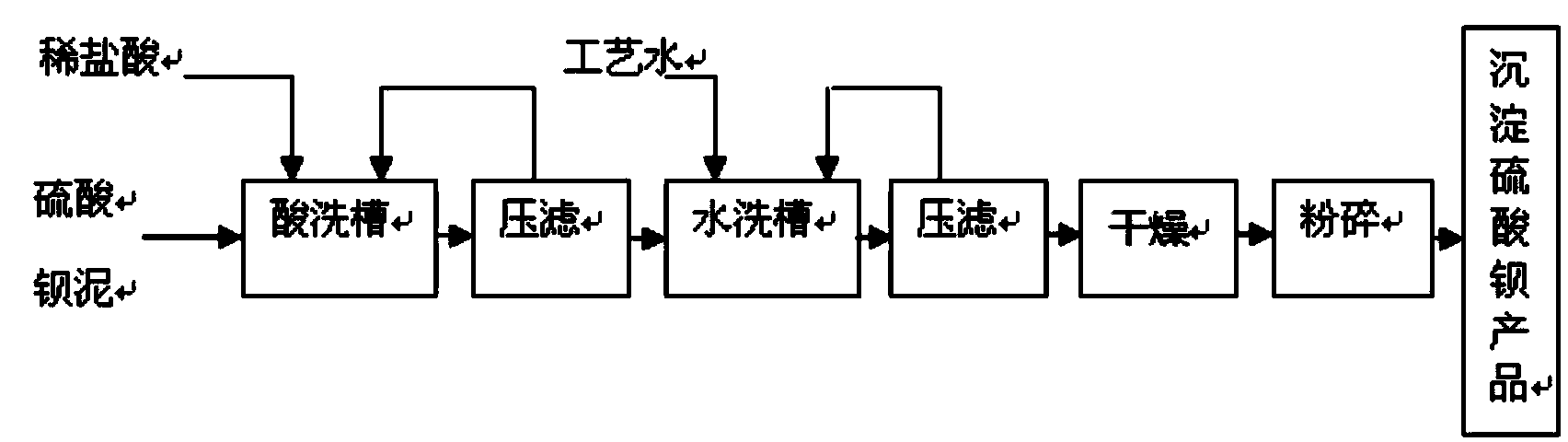

[0013] Using combined refined ammonium solid waste—barium sulfate mud as raw material, two-stage washing with solvents such as dilute hydrochloric acid and process water, two-stage pressure filtration, drying and crushing, to produce precipitated barium sulfate, which includes the following steps:

[0014] (1) The barium sulfate mud and dilute hydrochloric acid solution (hydrochloric acid concentration ≤ 25%) produced by the combined method of refined ammonium are stirred and washed in the pickling tank, and then press-filtered; the filtrate is returned to the pickling tank for recycling, and the filtrate in the pickling tank When it is neutral (PH value 6.5-6.8), the pumping refined ammonium production system is used to configure barium chloride solution.

[0015] (2) The filter cake and process water in step (1) are stirred and washed in the washing tank, and then press-filtered; the filtrate is returned to the washing tank for recycling, and when the filtrate in the washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com