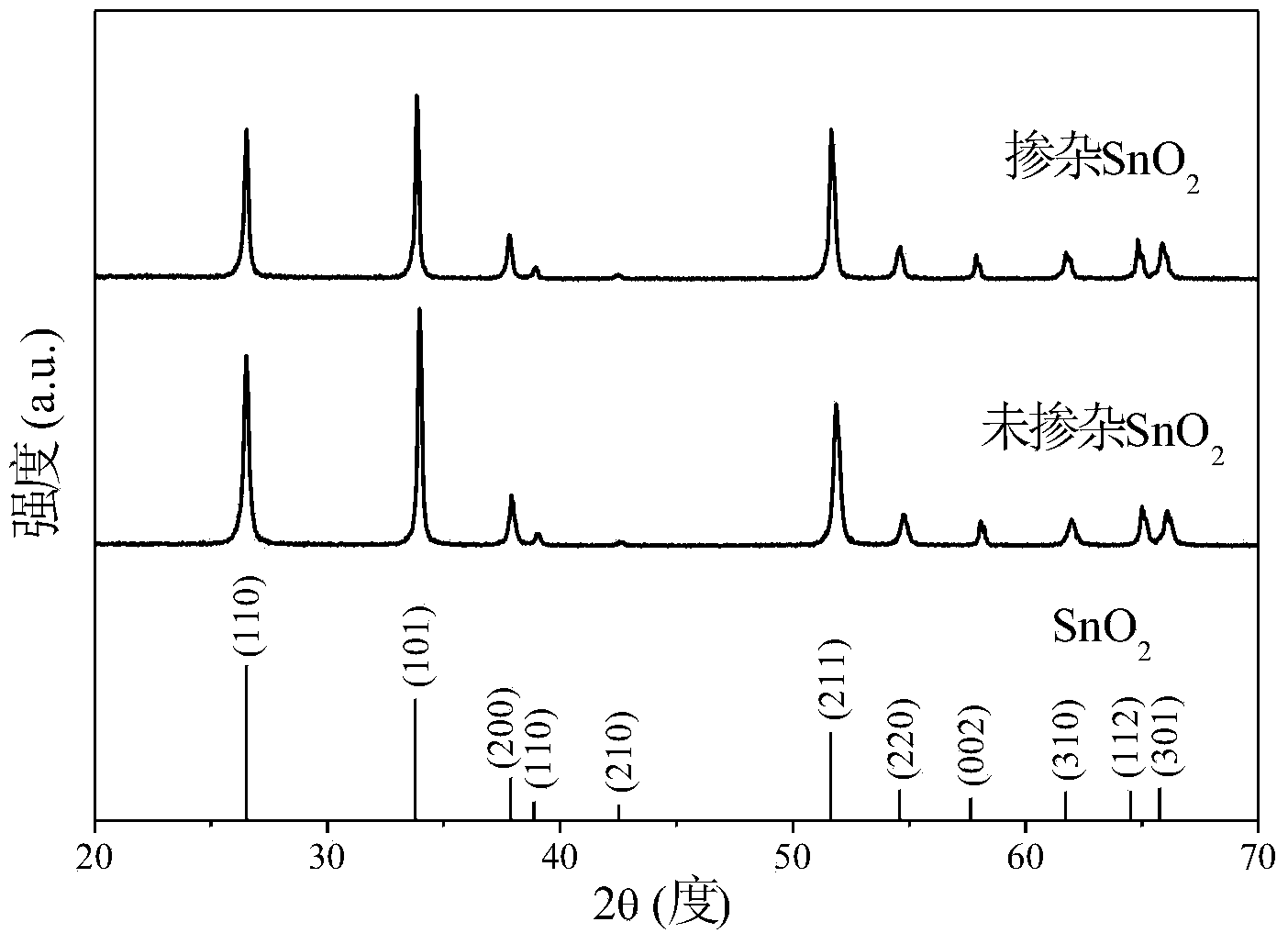

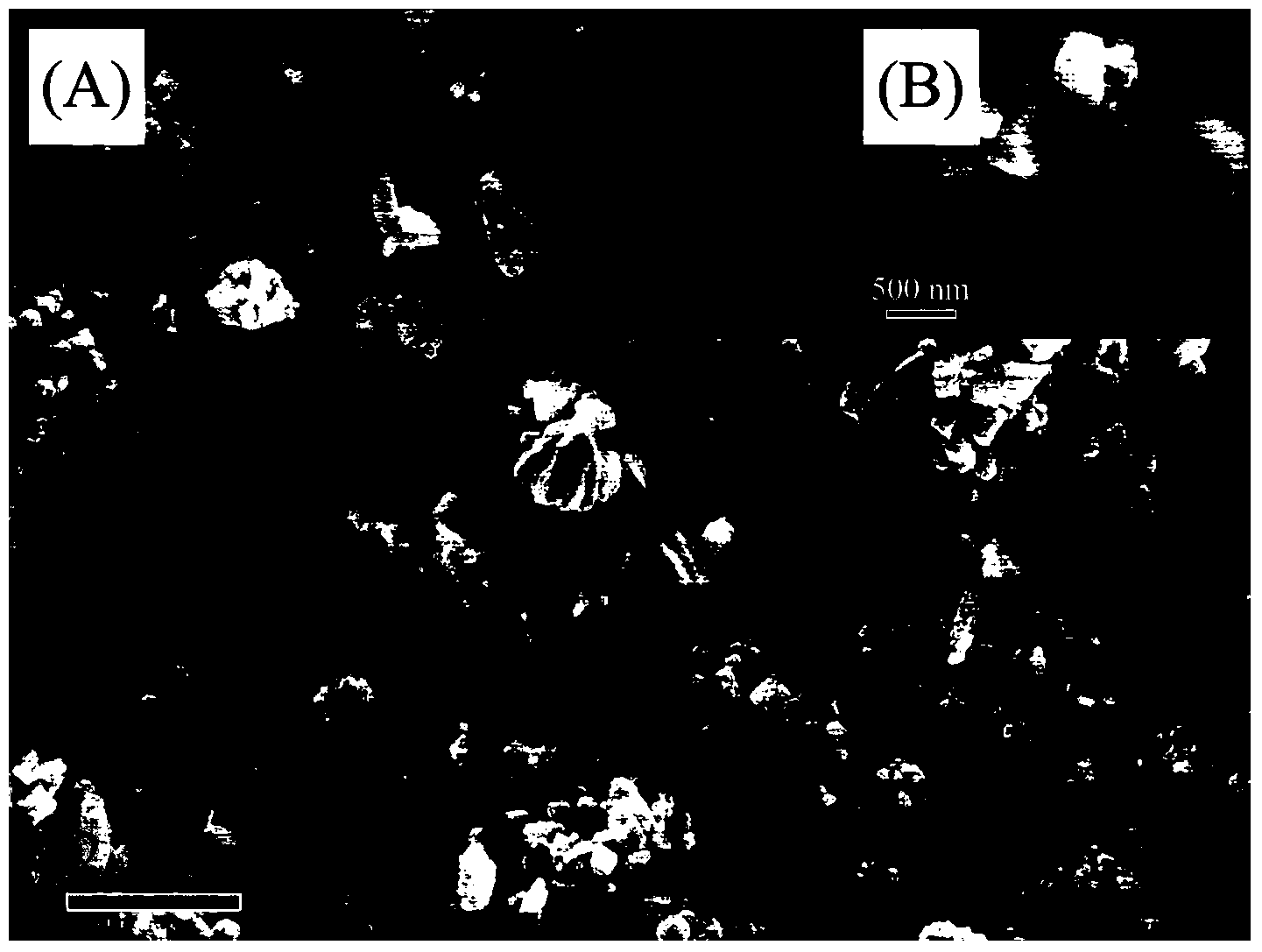

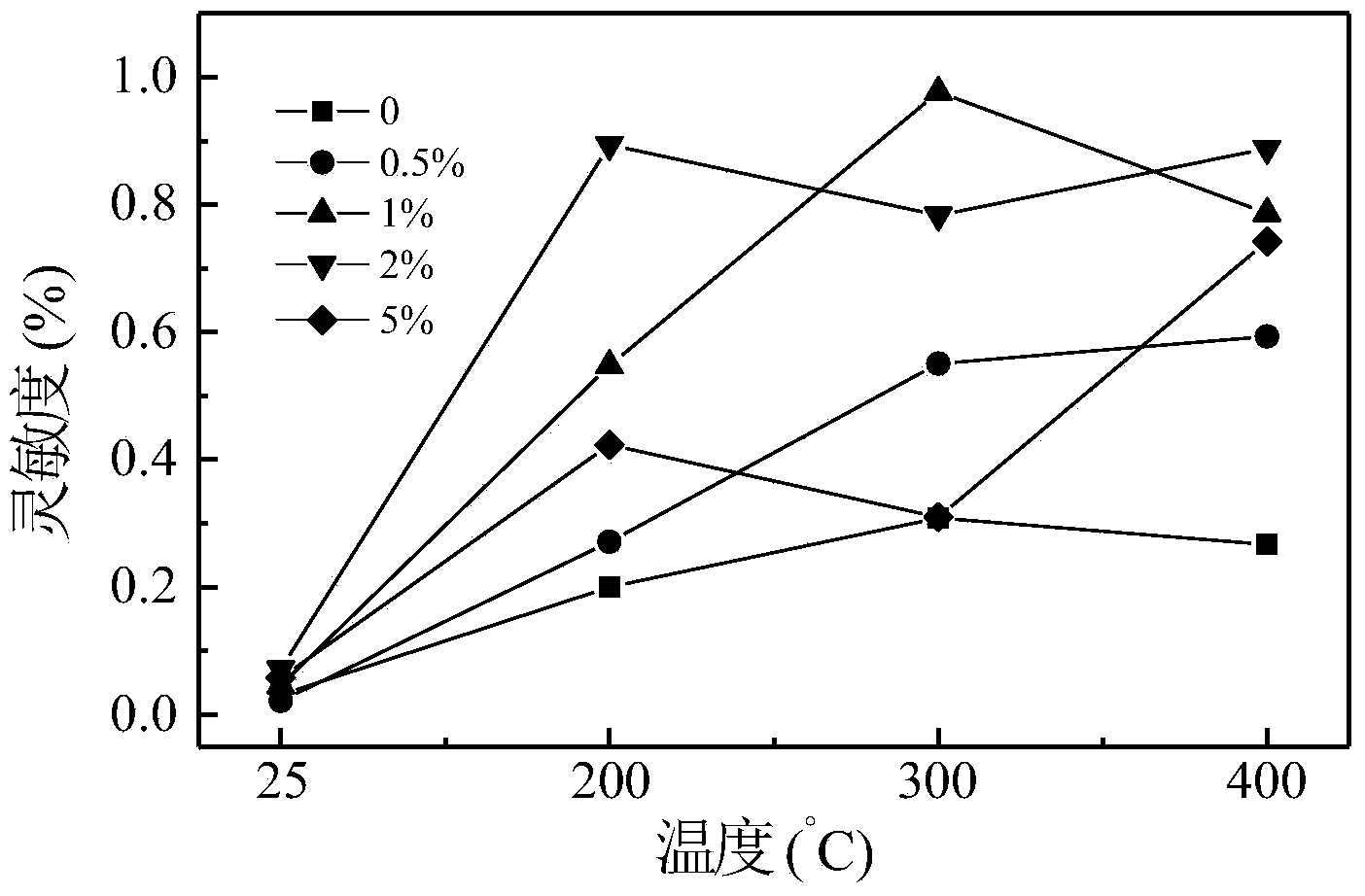

Preparation method of aluminum-doped tin dioxide flower-like micro-sphere/nano-rod gas sensitive material

A technology of flower-shaped microspheres and gas-sensitive materials, which is applied in the field of inorganic semiconductor sensor material preparation, can solve problems such as high cost, high doping, and complicated process, and achieve the effects of obvious advantages, simple process, and obvious hydrogen gas sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] SnO with a basicity of 6 2 Powder preparation: Weigh 0.5265g tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O) Dissolve in 20ml of absolute ethanol, weigh sodium hydroxide (NaOH) with an alkalinity of 6 and dissolve it in 20ml of deionized water; under the action of magnetic stirring, slowly add sodium hydroxide to the ethanol solution of tin tetrachloride pentahydrate In the aqueous solution, a white turbid solution was obtained after continuous stirring for 20 minutes; the white turbid solution was transferred into a 50ml polytetrafluoroethylene-lined stainless steel reaction kettle, heated to 200°C, kept for 6 hours, and then naturally cooled to room temperature; the obtained white precipitate Centrifuge and wash with deionized water and absolute ethanol several times respectively; add a certain amount of absolute ethanol to the washed precipitate, shake well, place in a blast drying oven, and dry at 80°C for 10 hours.

Embodiment 2

[0023] SnO with a basicity of 8 2 Powder preparation: the steps in this example are exactly the same as those in Example 1 above. The difference is: Weigh sodium hydroxide (NaOH) with an alkalinity of 8 and dissolve it in 20ml of deionized water.

Embodiment 3

[0025] SnO with a basicity of 10 2 Powder preparation: the steps in this example are exactly the same as those in Example 1 above. The difference is: Weigh sodium hydroxide (NaOH) with an alkalinity of 10 and dissolve it in 20ml of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com