A quartz sleeve for large-size optical fiber preform and its manufacturing method

An optical fiber preform and quartz sleeve technology, which can be used in manufacturing tools, glass manufacturing equipment, etc., can solve problems such as inability to meet, and achieve the effects of low manufacturing cost, high qualification rate, and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

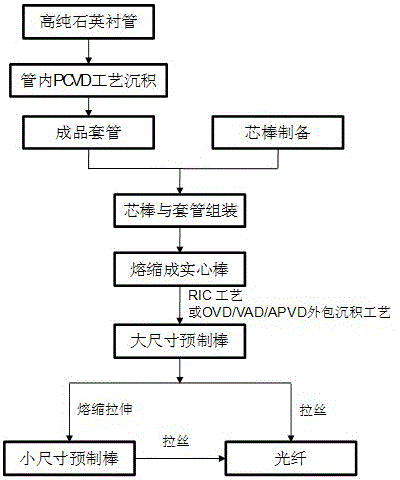

[0046] combine image 3 , 4 and figure 2 The process flow chart shown describes the preparation of a low-refractive-index fluorine-doped liner and an embodiment of using it to manufacture a bend-insensitive single-mode optical fiber.

[0047] Take a pure quartz liner with an outer diameter of 45mm, a wall thickness of 5mm, and a length of 1.7m, and extend both ends to match the fixtures at both ends of the PCVD deposition equipment. After corrosion and cleaning, carry out PCVD processing;

[0048] The processed liner is corroded and cleaned by soaking in AR grade hydrofluoric acid reagent to remove the internal and external surface contamination caused by the liner extension process. The inner and outer surfaces of the liner are washed with pure deionized water, and then the inner and outer surfaces are purged with pure nitrogen to fully dry;

[0049] The pure quartz liner is placed in a microwave resonant cavity holding furnace. The temperature in the holding furnace is k...

Embodiment 2

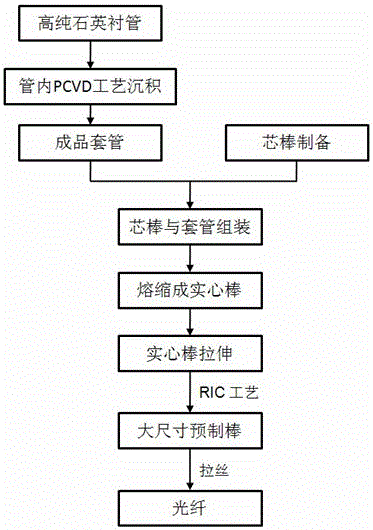

[0057] combine Figure 5 , 6 and image 3 The process flow chart shown describes the preparation of a low-refractive-index fluorine-doped sleeve and an embodiment of using it to manufacture a large effective area single-mode optical fiber with better bending properties.

[0058] Take a pure quartz liner with an outer diameter of 60mm, a wall thickness of 5.5mm, and a length of 1.7m, and extend both ends to match the fixtures at both ends of the PCVD deposition equipment; after etching and cleaning, perform PCVD processing;

[0059] The processed liner is corroded and cleaned by soaking in AR grade hydrofluoric acid reagent to remove the internal and external surface contamination caused by the liner extension process. The inner and outer surfaces of the liner are washed with pure deionized water, and then the inner and outer surfaces are purged with pure nitrogen to fully dry;

[0060] The pure quartz liner is placed in a microwave resonant cavity holding furnace. The tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com