Copolyester thermoplastic material used for three-dimensional printing, and preparation and application thereof

A thermoplastic material and three-dimensional printing technology, applied in the field of copolyester thermoplastic materials, can solve the problems of poor weather resistance and processing performance, and achieve the effects of strong processability, strong adhesion and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

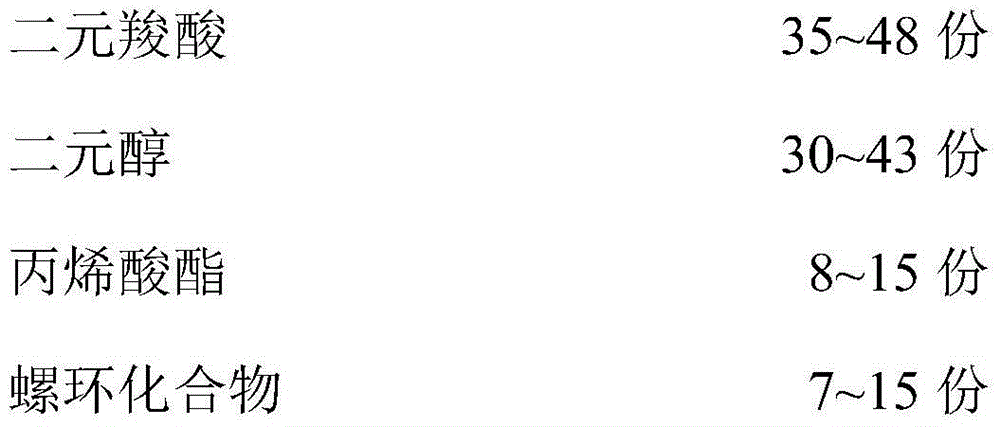

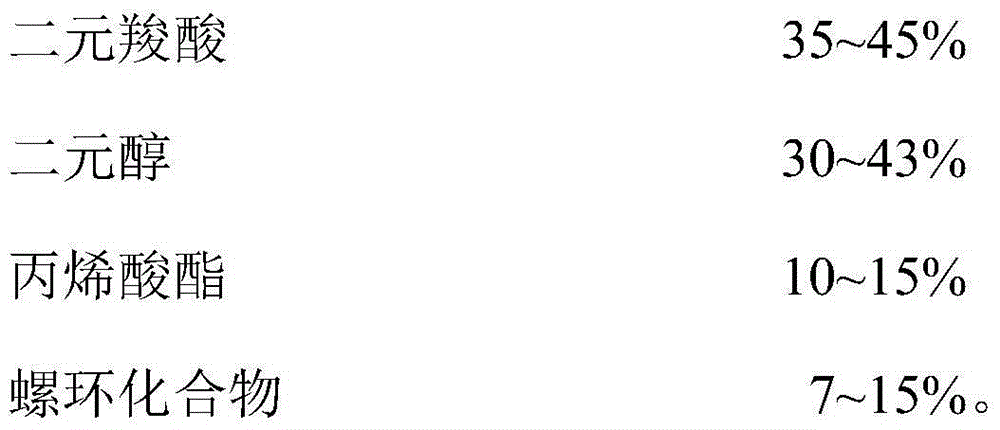

Method used

Image

Examples

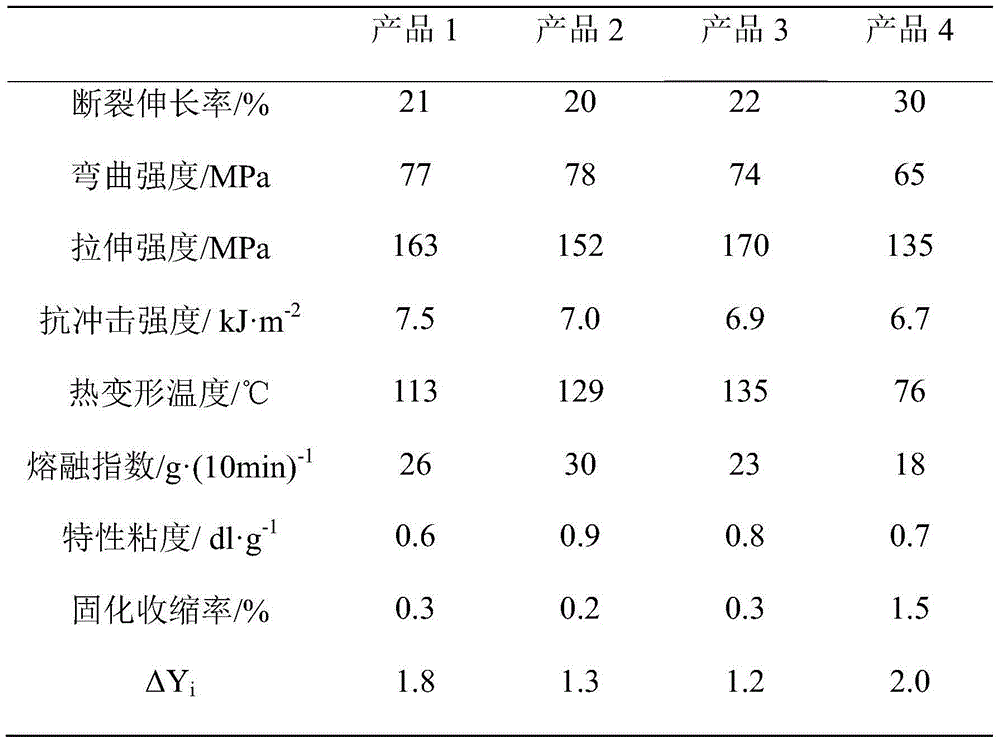

Embodiment 1

[0024] 35% by mass fraction of naphthalene dicarboxylic acid, 15% by mass fraction of neopentyl glycol, 28% by mass fraction of 1,4-cyclohexanedimethanol, 8% by mass fraction of epoxy acrylate, 7% by mass fraction of Neopentyl glycol diacrylate and 7% mass fraction of spiro ring orthoester monomer were added to the reactor, and 0.002% mass fraction of tetrabutyl titanate and antimony acetate (mass ratio was 1:1) composite catalyst was added . Then the temperature was raised and stirring was started, and the temperature in the kettle was controlled at 220° C. and the pressure at 0.2 MPa. During the experiment, the generated esterification water was gradually released. When the generated esterification water reached more than 90% of the theoretical amount, it indicated that the esterification reaction was completed and the reaction entered the polycondensation reaction stage. When the temperature rises to about 260°C, vacuuming begins slowly. First, pre-condensation is carried ...

Embodiment 2

[0026] 30% by mass fraction of naphthalene dicarboxylic acid, 15% by mass fraction of adipic acid, 31% by mass fraction of neopentyl glycol, 10% by mass fraction of neopentyl glycol diacrylate, 10% by mass fraction of spirogen Ester and 4% mass fraction of bicyclic ortho ester monomers were added to the reactor, and 0.008% mass fraction of tetrabutyl titanate and antimony acetate (mass ratio 1:1) composite catalyst was added at the same time. Then the temperature was raised and stirring was started, and the temperature in the kettle was controlled at 220° C. and the pressure at 0.2 MPa. During the experiment, the generated esterification water was gradually released. When the generated esterification water reached more than 90% of the theoretical amount, it indicated that the esterification reaction was completed and the reaction entered the polycondensation reaction stage. When the temperature rises to about 260°C, vacuuming begins slowly. First, pre-condensation is carried o...

Embodiment 3

[0028] 30% by mass fraction of naphthalene dicarboxylic acid, 18% by mass fraction of adipic acid, 20% by mass fraction of neopentyl glycol, 10% by mass fraction of 1,4-cyclohexanedimethanol, 10% by mass fraction of neopentyl glycol Pentylene glycol diacrylate and 12% mass fraction of spiro ring orthoester monomer were added to the reactor, and 0.002% mass fraction of tetrabutyl titanate and antimony acetate (mass ratio: 1:1) composite catalyst was added at the same time. Then the temperature was raised and stirring was started, and the temperature in the kettle was controlled at 220° C. and the pressure at 0.2 MPa. During the experiment, the generated esterification water was gradually released. When the generated esterification water reached more than 90% of the theoretical amount, it indicated that the esterification reaction was completed and the reaction entered the polycondensation reaction stage. When the temperature rises to about 260°C, vacuuming begins slowly. First,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com