Highly cross-linked polyphosphazene hollow microspheres as well as preparation method thereof

A technology of hollow microspheres and polyphosphazene, which is applied in the field of polyphosphazene hollow microspheres and its preparation, can solve the problems of heating, the specific surface area of microspheres is difficult to meet the needs of industrial adsorption, and the high requirements of the preparation process, and achieve excellent solvent resistance , The preparation process is simple and easy, and the method is novel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 0.2088 g of hexachlorocyclotriphosphazene, 0.8352 g of 4,4-dimercaptobisthiophenol, and 0.5 mL of triethylamine into a 150 mL flask, and dissolve in 100 mL of acetonitrile. Under mechanical stirring, react at room temperature for 1 hour, then centrifuge the precipitate, wash with tetrahydrofuran and deionized water three times, and finally dry in a vacuum oven for 24 hours to obtain cross-linked polyphosphazene hollow microspheres.

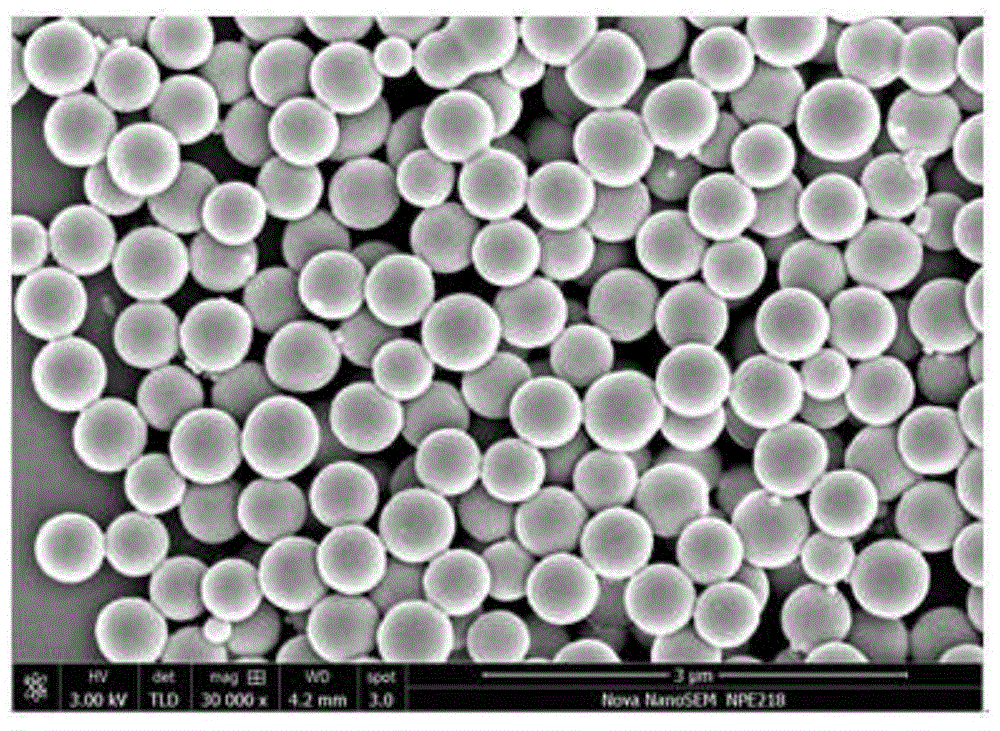

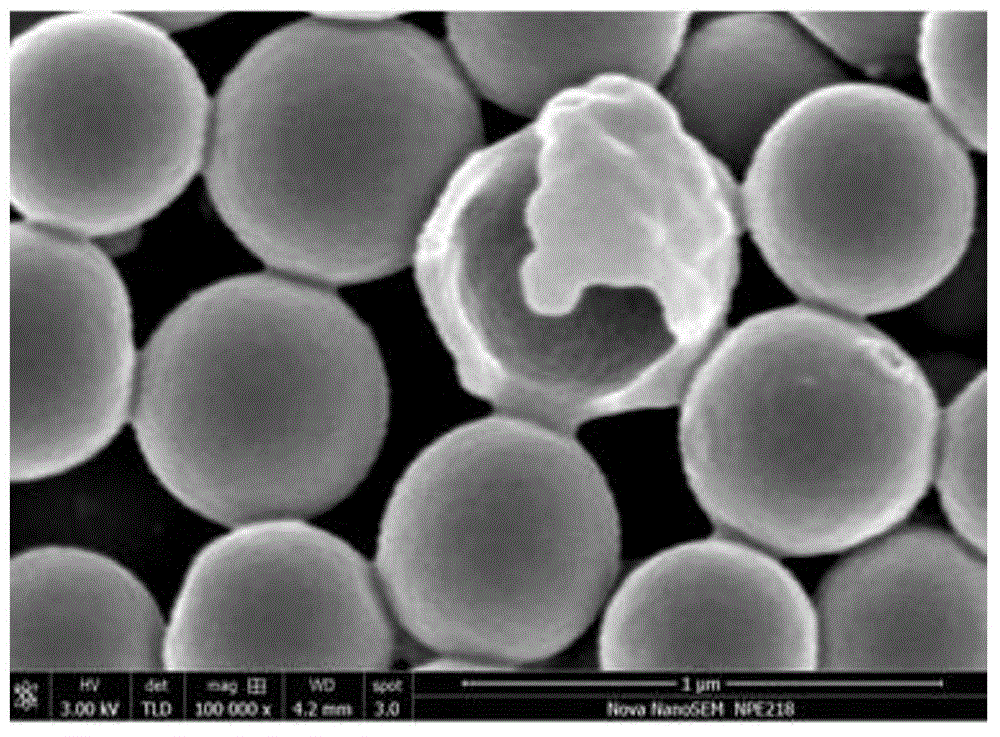

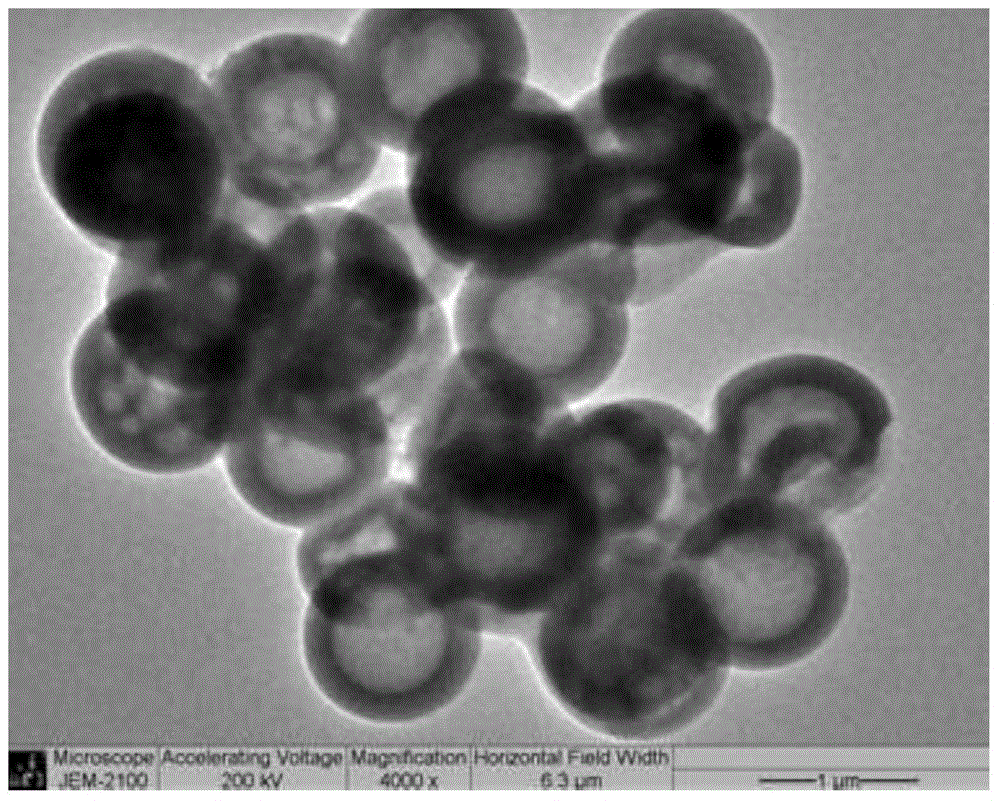

[0031] figure 1 , figure 2 The low-magnification and high-magnification scanning electron microscope pictures of the obtained polyphosphazene hollow microspheres are respectively. image 3 It is a transmission electron microscope picture of the obtained polyphosphazene hollow microspheres. Both indicate that the obtained microspheres are hollow structures.

[0032] Figure 4 It is the infrared spectrum of cross-linked polyphosphazene hollow microspheres. Wherein a is polyphosphazene, and b is 4,4-dimercaptobisthiophenol. It can b...

Embodiment 2

[0035] Add 0.2088 g of hexachlorocyclotriphosphazene, 0.8352 g of 4,4-dimercaptobisthiol, and 0.5 mL of triethylamine into a 150 mL flask, and dissolve in 100 mL of acetone. Under mechanical stirring, react at room temperature for 2 hours, then centrifuge the precipitate, wash three times with tetrahydrofuran and deionized water, and finally dry in a vacuum oven for 24 hours to obtain cross-linked polyphosphazene hollow microspheres.

Embodiment 3

[0037] Add 0.2088 g of hexachlorocyclotriphosphazene (one part), 0.8352 g of 4,4-dimercaptobisthiophenol (two parts), and 0.5 mL of triethylamine into a 150 mL flask, and dissolve with 50 mL of acetone. Under the action of ultrasound, react at room temperature for 2 hours, then centrifuge the precipitate, wash with tetrahydrofuran and deionized water three times, and finally dry in a vacuum oven for 24 hours to obtain cross-linked polyphosphazene hollow microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com