Halogen-free flame retardant, halogen-free flame-retardant polyolefin composition and application thereof

A flame retardant and polyolefin technology, applied in the field of halogen-free flame retardants and halogen-free flame retardant polyolefin compositions, can solve the problems of poor compatibility and large addition amount, achieve high blending efficiency and improve use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples are used to further illustrate the present invention, and should not be interpreted as limiting the protection scope of the present invention. Those skilled in the art can make some non-essential improvements and adjustments to the present invention according to the above-mentioned content of the present invention.

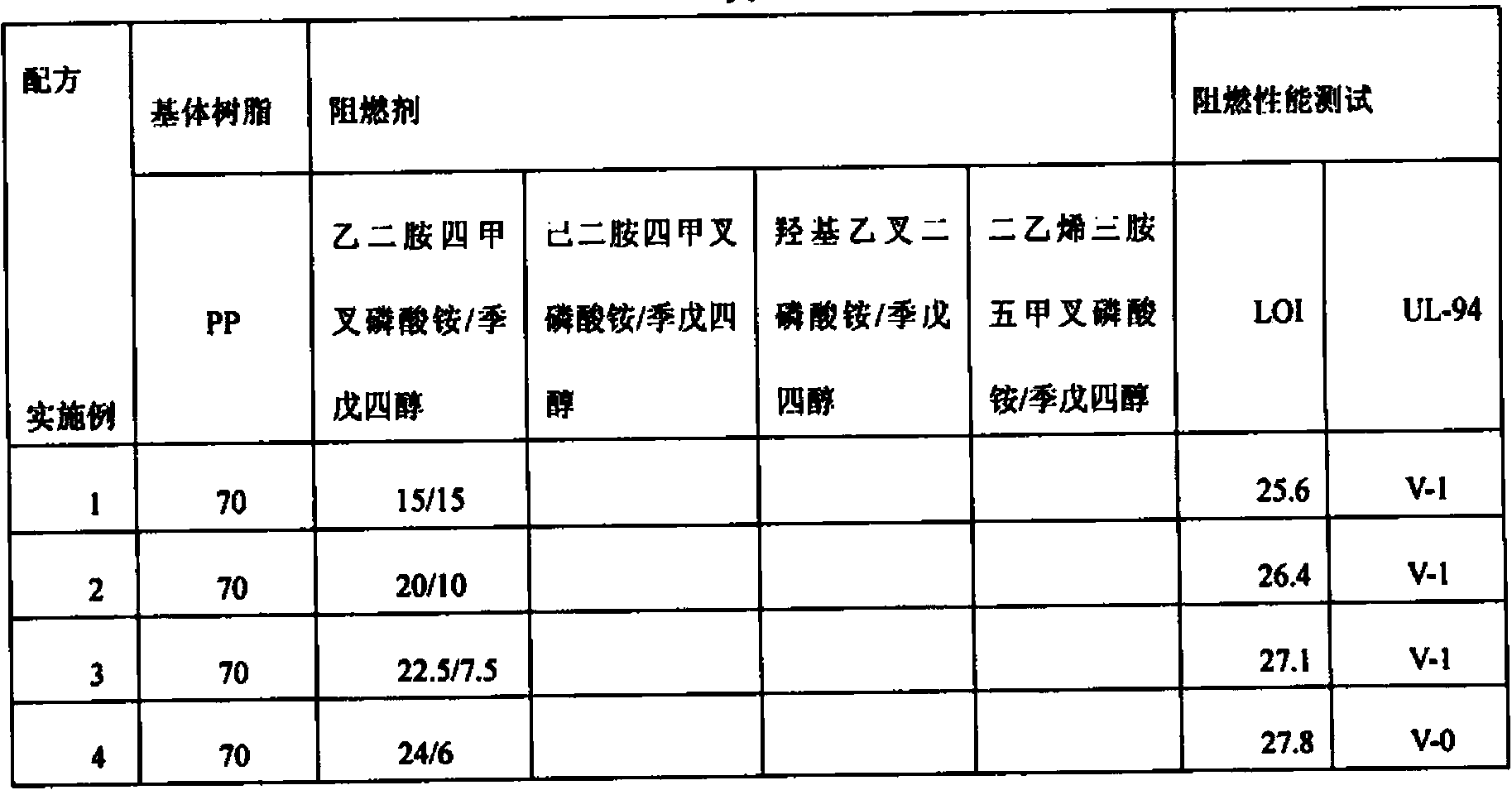

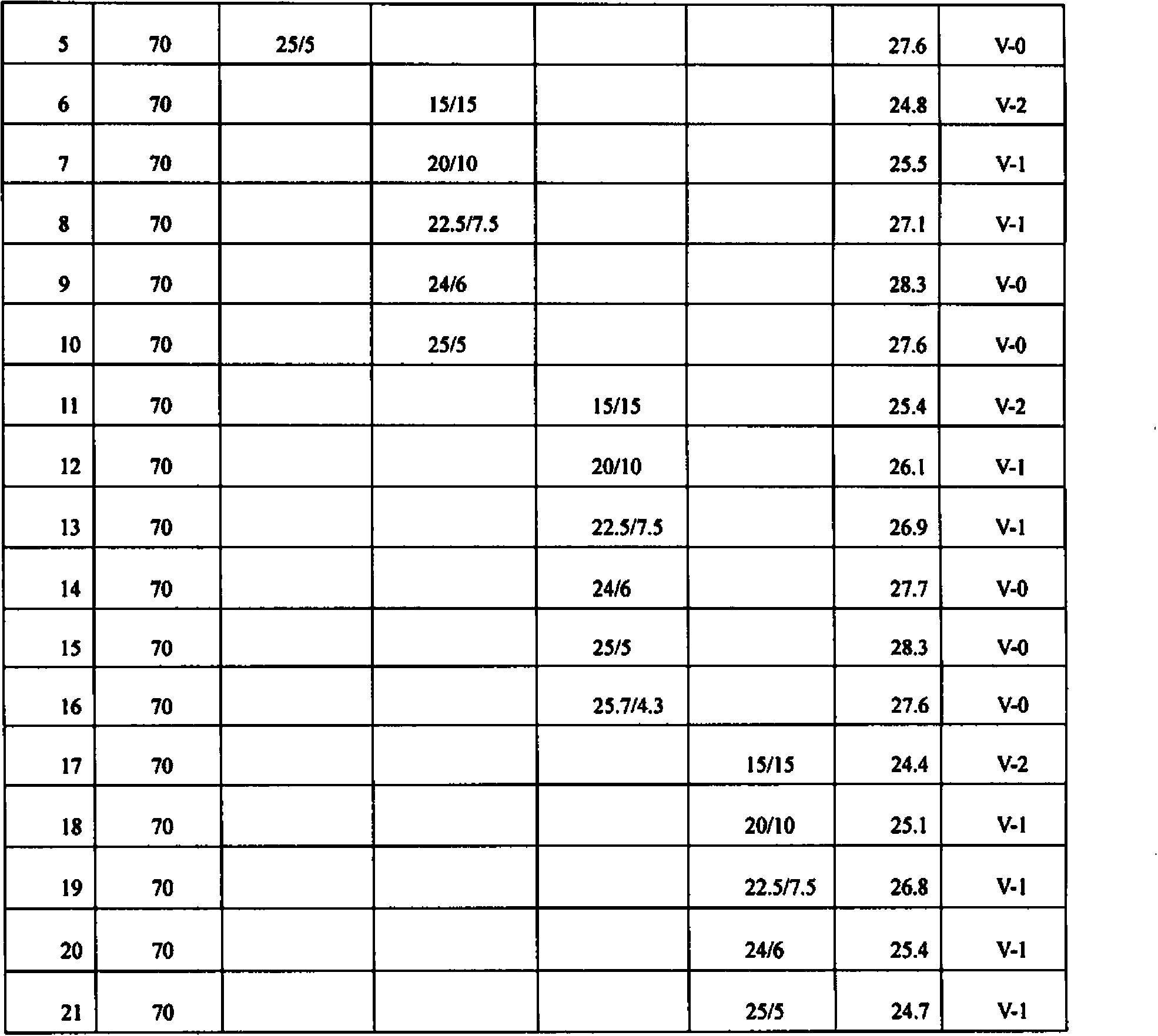

[0034] Table 1 has listed the raw material formula and performance test data of embodiment 1-21.

[0035] Table 1

[0036]

[0037]

[0038] Note: PP is polypropylene

[0039] in:

[0040] The operation process of embodiment 1-5 is as follows:

[0041] 1. Formula blending and pretreatment

[0042] Mix ethylenediamine tetramethylene ammonium phosphonate and pentaerythritol according to the mass ratio listed in the table. The flame retardant system accounts for 30% of the total system mass. Blending is carried out with a high-speed mixer, and the control speed is 6000 rpm , the temperature was controlled at 70°C, and blended f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com