Polyester resin extruding light-emitting plate and preparation method thereof

A technology of polyester resin and board, which is applied in the field of long afterglow luminous board and its preparation, can solve the problems such as the preparation process of extruded luminous board without polyester resin, achieve the improvement of luminous brightness and afterglow time, the product is energy-saving and environmentally friendly, and has good physical and chemical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

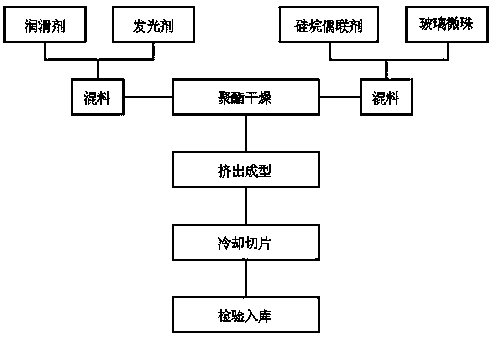

[0040] The preparation method of the polyester resin extruded luminescent plate of the present invention is to separately mix the high refractive index ultrafine hollow glass microspheres, the silane coupling agent, the luminescent agent and the lubricant, mix them into the base material thermoplastic polyester resin, dry, heat the plastic melted, melt extruded, rolled and formed by cooling rolls. Specifically, the present invention comprises the following steps:

[0041] (1) Activate the glass microspheres and the silane coupling agent, stir and mix them, and then dry them. Wherein: the stirring and mixing of the glass microspheres and the silane coupling agent is as follows: first stirring at a low speed for 1 to 3 minutes, then stirring and mixing at a high speed for 4 to 8 minutes, and then drying at 120 to 160° C. for 2 to 3 hours.

[0042] (2) Stir and mix the luminescent agent and lubricant. Among them: the luminescent agent is 200-300 mesh aluminate luminescent agent...

Embodiment 1

[0047] The glass microspheres and the silane coupling agent must be activated. Stir at a low speed for 2 minutes, then stir at a high speed for 5 minutes, then add 0.5-1% of the diffusing oil agent to some raw materials, and then add 8-10% of the luminescent agent. Add them to the PET silo, stir evenly, and dry them so that the moisture content of the PET is lower than 50PPM. Put them into the extruder to heat, melt and extrude them. After cooling and shaping through the connectors, die heads, and cooling rollers, they are finally sliced and inspected for storage.

[0048] Its weight ratio of raw material formula is as follows:

[0049] PET: 65-85%

[0050] Glass beads: 15-20%

[0051] Luminescent agent: 5~10%

[0052]Coupling agent: 0.5~2%

[0053] Lubricant: 0.5~2%

[0054] The ratio of glass microspheres, luminescent agent and carrier PET can be adjusted according to needs.

[0055] The process parameters of each step are as follows:

[0056] The drying temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com