A kind of high flame-retardant glass fiber air filter paper and preparation method thereof

A technology of air filter paper and glass fiber, applied in the direction of filter paper, synthetic cellulose/non-cellulose material pulp/paper, filter separation, etc., can solve the problem of glass fiber air filter paper losing its air filtration function, incapable of flame retardancy, and accelerating fire and other problems, to achieve high strength, uniform and fine gaps, and good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

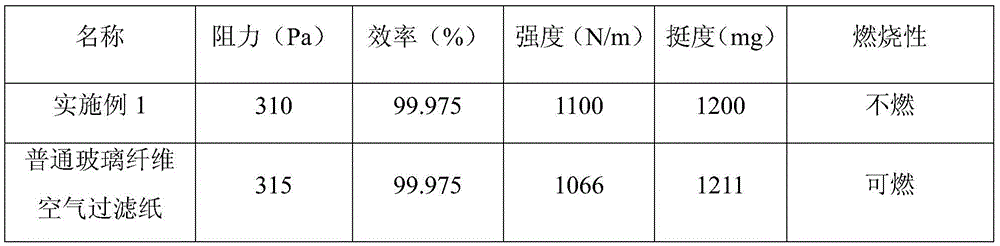

Examples

Embodiment 1

[0023] This embodiment prepares the method for high flame-retardant glass fiber air filter paper, comprises the following steps:

[0024] (1) Raw material preparation: Select the non-alkali glass fiber cotton with a diameter of 7-9 μm and the non-alkali glass fiber cotton with a diameter of 0.3-0.4 μm according to the mass ratio of 1:4;

[0025] (2) Dispersed pulping: Add the raw materials selected in step (1) into the beater and disperse for 25 minutes, then add clear water to make the slurry mass concentration 2.2%, then add sulfuric acid solution to adjust the slurry pH=3.8;

[0026] (3) Wet forming: Dilute the slurry obtained in step (2) to a mass concentration of 0.2% and perform slag removal treatment, then transport the slurry to an inclined wire former to form wet paper;

[0027] (4) Spraying sizing material: the wet paper obtained in step (3) is sprayed with glue, and the sprayed bonding sizing material is a mixture of acrylic acid emulsion and halogen-free organic ph...

Embodiment 2

[0031] This embodiment prepares the method for high flame-retardant glass fiber air filter paper, comprises the following steps:

[0032] (1) Raw material preparation: select the non-alkali glass fiber cotton with a diameter of 7-9 μm and the non-alkali glass fiber cotton with a diameter of 0.3-0.4 μm according to the mass ratio of 1:3.8;

[0033] (2) Dispersed pulping: Add the raw materials selected in step (1) into a beater for beating and disperse for 25 minutes, then add clear water to make the slurry mass concentration 2.5%, then add sulfuric acid solution to adjust the slurry pH=4.0;

[0034] (3) Wet forming: Dilute the slurry obtained in step (2) to a mass concentration of 0.3% and perform slag removal treatment, then transport the slurry to an inclined wire former to form wet paper;

[0035] (4) Spraying sizing material: the wet paper obtained in step (3) is sprayed and processed, and the sprayed bonding sizing material is a mixture of acrylic acid emulsion and organic...

Embodiment 3

[0039] This embodiment prepares the method for high flame-retardant glass fiber air filter paper, comprises the following steps:

[0040] (1) Raw material preparation: Select the non-alkali glass fiber cotton with a diameter of 7-9 μm and the non-alkali glass fiber cotton with a diameter of 0.3-0.4 μm according to the mass ratio of 1:4.2;

[0041] (2) Dispersed pulping: Add the raw materials selected in step (1) into a beater for beating and disperse for 25 minutes, then add clear water to make the slurry mass concentration 2.0%, then add sulfuric acid solution to adjust the slurry pH=3.5;

[0042] (3) Wet forming: Dilute the slurry obtained in step (2) to a mass concentration of 0.1% and perform slag removal treatment, then transport the slurry to an inclined wire former to form wet paper;

[0043] (4) glue spraying: step (3) gained wet paper is carried out glue spraying treatment, and the glue sprayed is acrylic acid emulsion and organic phosphate mixture;

[0044] (5) Suct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com