an ultraviolet generator

A generator and ultraviolet technology, applied in X-ray tubes, X-ray equipment, X-ray tubes with huge currents, etc., can solve problems such as large pollution, material aging, sputtering of cavity consumables, etc., and achieve an increase in spectral energy maintenance rate , Solve the effect of short service life and pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

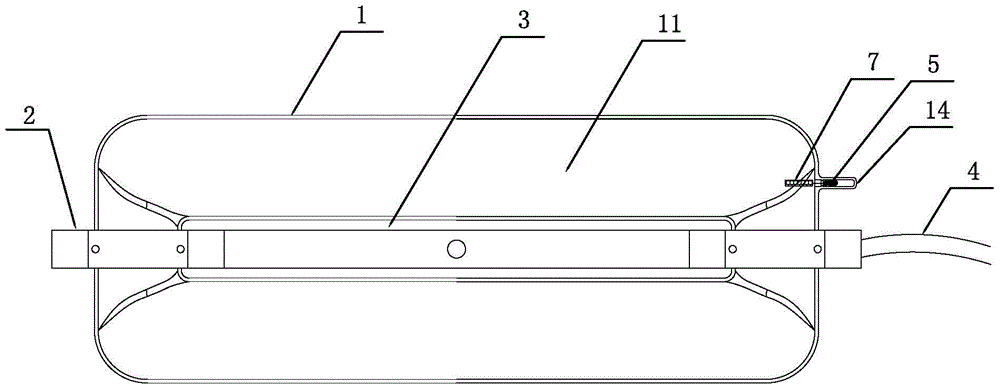

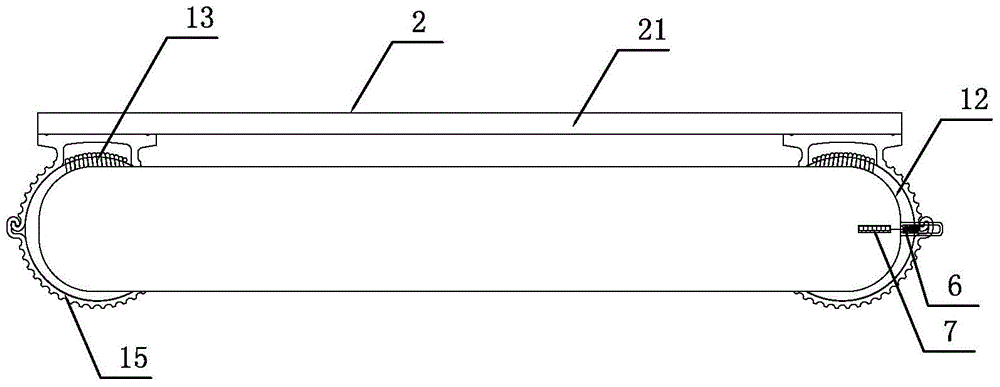

[0017] An ultraviolet generator, comprising a body 1, and a fixed bracket 2 arranged on the upper end of the body, wherein the body is a sealed cavity 11 made of quartz glass tube, with a through hole 3 in the middle, and the two ends of the body 1 are arranged symmetrically There is a magnetic ring 12, and the top of the magnetic ring 12 is provided with an induction coil 13, and the induction coil 13 is connected to the high-frequency generator through the connecting wire 4; the main body 1 is further provided with an amalgam containing chamber that communicates with the closed cavity of the main body 14. The amalgam 5 is placed in the above-mentioned containing chamber 14, and the mouth of the amalgam containing chamber 14 is provided with a molybdenum wire 6, and the stainless steel indium mesh 7 is connected to the molybdenum wire 6.

[0018] The magnetic ring 12 is provided with a boi 15, which is used to fix the magnetic ring 12 on the one hand, and is used to connect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com