Novel technology for dark green tea fermentation

A fermentation process and a new process technology, applied in tea treatment before extraction, etc., can solve the problems of uneven color, unsatisfactory, bitter and astringent taste of new tea, etc., and achieve the effect of pure tea aroma, soft taste and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

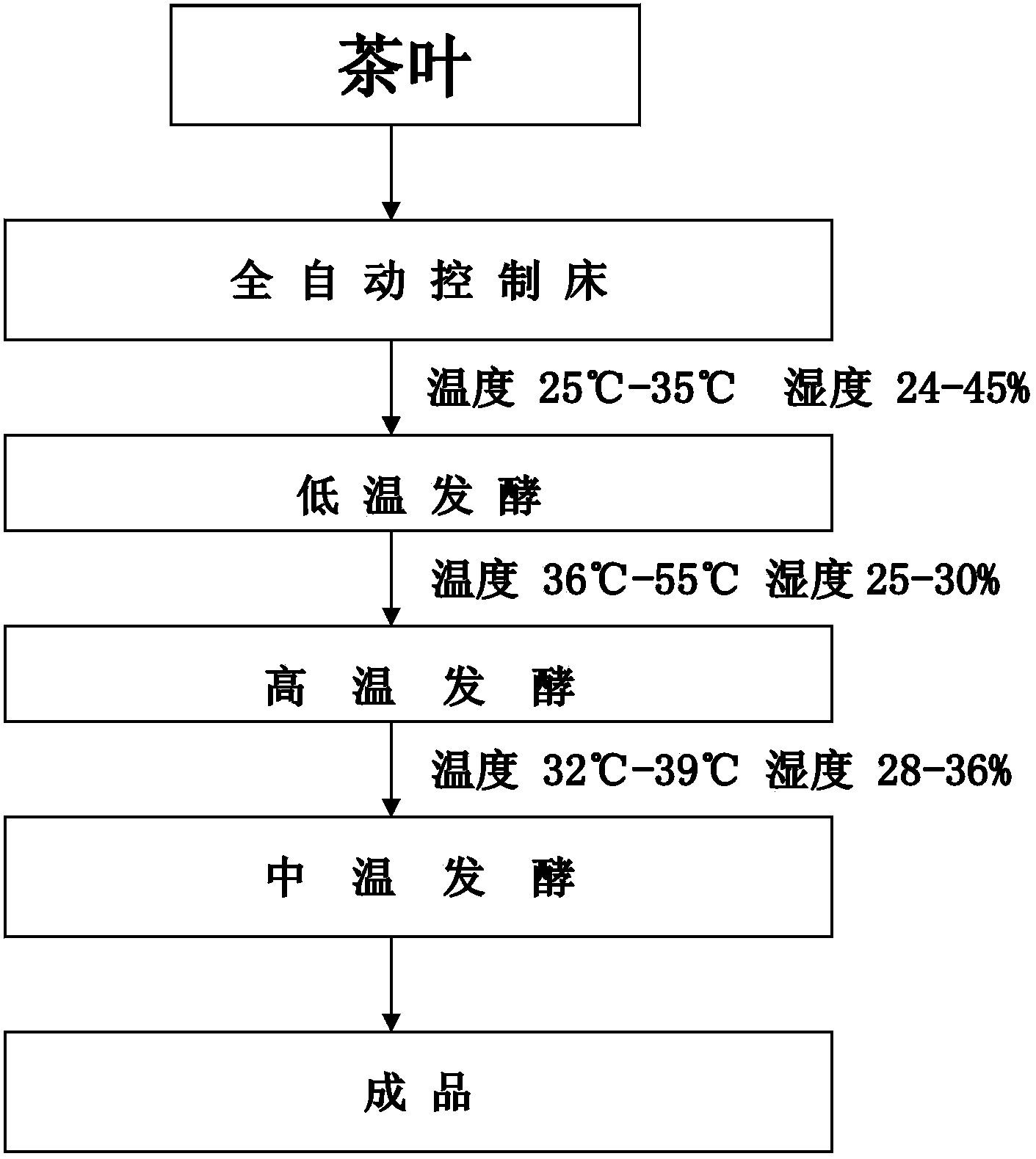

[0014] Now in conjunction with accompanying drawing, the present invention will be further described:

[0015] The invention adopts a fully automatic fermenting bed to strictly control the temperature and humidity in the dark tea fermentation process, and complete each process of dark tea fermentation fully automatically. Usually, the new technology of fermenting black tea is to spread green tea leaves, finish them, and knead them before heaping and fermenting. The feature is that the so-called heaping fermentation is carried out in three stages:

[0016] a. Low-temperature fermentation: the temperature is controlled at 25°C-35°C, the humidity is controlled at 24-45%, and the pile is piled up for about 24 hours. At this stage, yeast is cultivated, and carbon dioxide is generated by the yeast to decompose caffeine and caffeine in the tea;

[0017] b. High-temperature fermentation: ferment at a temperature of 36°C-55°C, humidity at 25-30%, and pile up for about 12 hours, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com