Hog grower feed

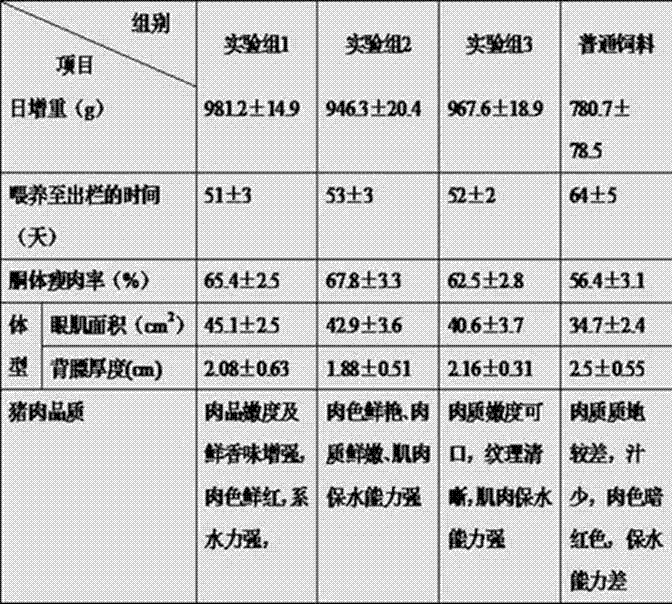

A large pig feed and raw material technology, applied in animal feed, animal feed, applications, etc., can solve the problems of unable to meet the growth needs of large pigs, affect the health of consumers, affect the quality of pork, etc., to improve the utilization rate of feed, significantly economical Benefits, the effect of increasing lean meat percentage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The weight ratio between the ingredients is: 460 parts of corn, 100 parts of sub-flour, 100 parts of oil bran, 100 parts of ao skin, 190 parts of low-temperature soybean meal, 6 parts of stone powder, 8 parts of calcium hydrogen phosphate, 5 parts of salt, and 1 part of baking soda. Parts, 1 part of choline chloride, 2 parts of antifungal agent, 0.3 parts of antioxidants, and 26.7 parts of core material; the core material includes the following raw materials and parts by weight: 44 parts of green tea tea residue, 10 parts of grapefruit peel, multivitamin 2.5 parts, 15 parts of lysine, 8.5 parts of L-cysteine, 10 parts of betaine, 5 parts of chromium yeast and 5 parts of manganese yeast.

Embodiment 2

[0037] The weight ratios of the ingredients are: 410 parts of corn, 90 parts of sub-flour, 110 parts of oil bran, 120 parts of ao bark, 180 parts of low-temperature soybean meal, 5 parts of stone powder, 7 parts of calcium hydrogen phosphate, 7 parts of salt, and 1 part of baking soda. Parts, 1 part of choline chloride, 2 parts of antifungal agent, 0.3 parts of antioxidant and 23.7 parts of core material;

[0038] The core material is 44 parts of black tea and tea residue, 15 parts of grapefruit peel, 3.5 parts of multivitamins, 8 parts of lysine, 8.5 parts of L-cysteine, 11 parts of betaine, 5 parts of chromium yeast and 5 parts of manganese yeast.

Embodiment 3

[0040] The weight ratio between the ingredients is: 510 parts of corn, 85 parts of sub-flour, 85 parts of oil bran, 120 parts of ao bark, 180 parts of low-temperature soybean meal, 5 parts of stone powder, 8 parts of calcium hydrogen phosphate, 6 parts of salt, 0.5 parts of baking soda Parts, 1 part of choline chloride, 1 part of antifungal agent, 0.1 part of antioxidant, and 28.4 parts of core material; 45 parts of dry green tea residue powder, 10 parts of grapefruit peel dry powder, 4 parts of multivitamin, lysine 15 parts, 10 parts L-cysteine, 10 parts betaine, 3 parts chromium yeast, and 3 parts manganese yeast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com