Preparation method of microcapsule-supported metal complex catalyst

A technology of metal complexes and catalysts, which is applied in the field of preparation of catalyst materials, can solve problems such as catalyst instability and deactivation, and achieve the effects of improving stability, reducing processing costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

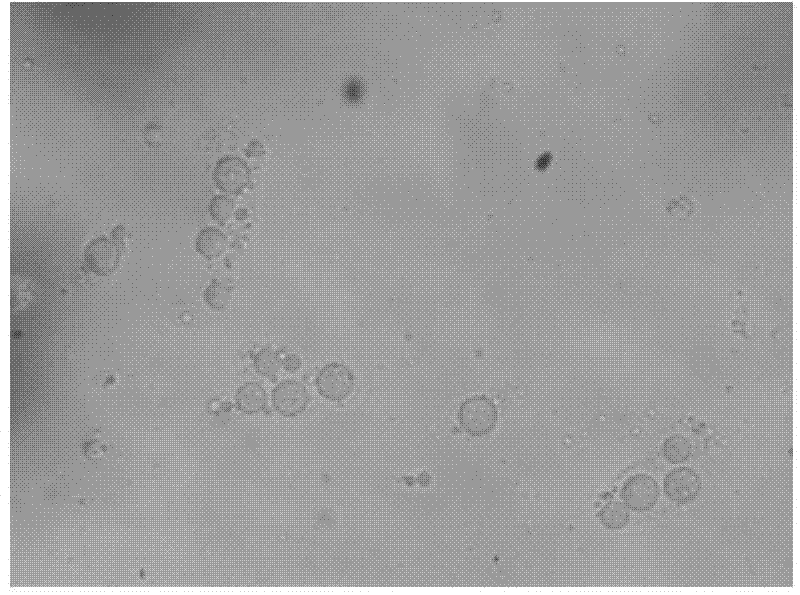

[0027] Preparation of microcapsule-loaded metal complex catalysts by double emulsion solvent evaporation: 30 mg of cyclic polyamine manganese complexes were dissolved in 6 ml of deionized water to obtain an aqueous core material solution. Fully dissolve 3 g of ethyl cellulose with 50 ml of dichloromethane to obtain a wall material solution. Stir and emulsify the aqueous solution of the core material and the dichloromethane solution of the wall material at a speed of 4000r / m, quickly pour it into the 500ml external aqueous phase solution prepared in advance, and continuously stir and emulsify at a speed of 400r / m for 60min, then put The ambient temperature was maintained at about 30° C., and the stirring and volatilization was continued to ensure that the dichloromethane therein volatilized completely. Afterwards, the resulting suspension was centrifuged at a speed of 5000 r / m to collect the product, washed with deionized water, and freeze-dried. The resulting product is tenta...

Embodiment 2

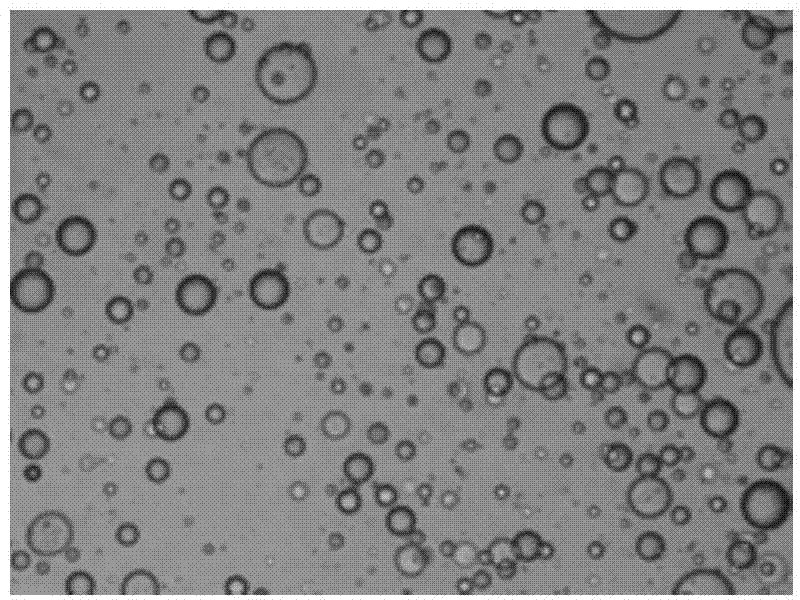

[0029] Preparation of microcapsule-supported metal complex catalysts by emulsification cross-linking method: 1 g of gelatin was completely dissolved in 10 ml of deionized water, and then 20 mg of cyclopolyamine manganese complex was dissolved therein. Emulsify the aqueous solution of the mixture obtained above into 100ml of paraffin at a stirring speed of 400r / m, cross-link the emulsified emulsion with glutaraldehyde in an ice bath, then filter out the solidified product, wash and dry . The resulting product is tentatively labeled as 2# catalyst.

Embodiment 3

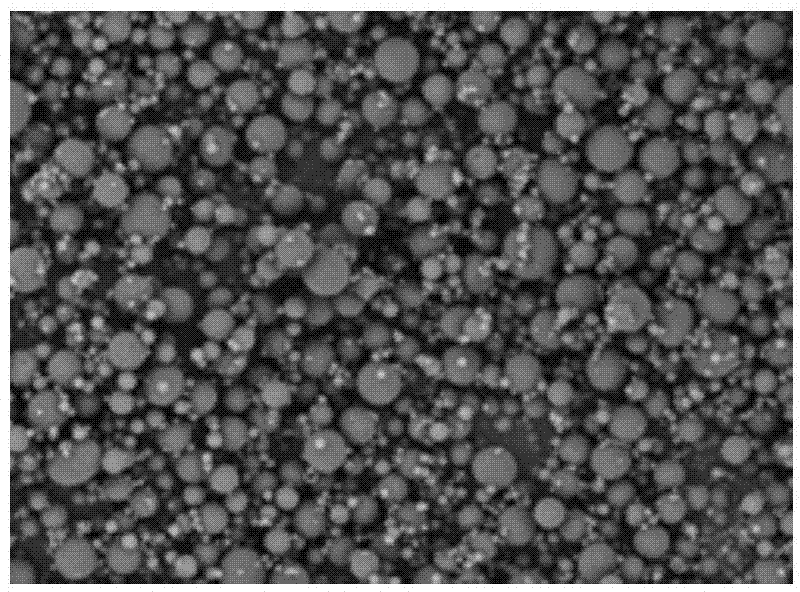

[0031] Preparation of microcapsule-loaded metal complex catalysts by drying in liquid: 30 mg of cyclic polyamine manganese complex and 2 g of ethyl cellulose were fully dissolved in 20 ml of acetone, and added to 100 ml of paraffin. 400r / m emulsification and stirring, and then continue stirring the obtained emulsion at 40°C until the acetone solvent is fully volatilized, and the solidified product is filtered out, washed and dried. The resulting product is tentatively labeled as 3# catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com