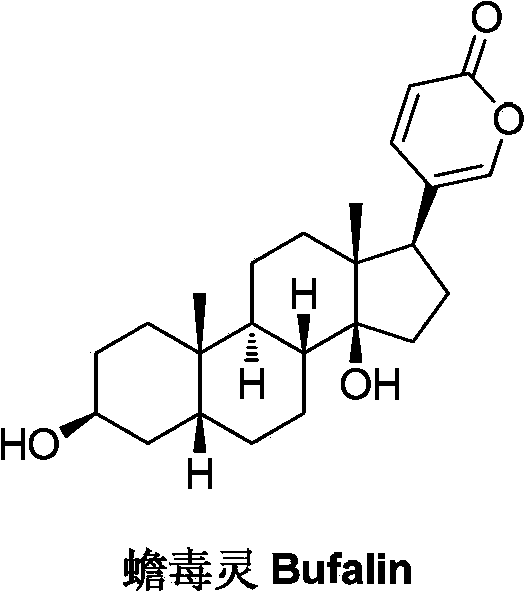

Bufalin derivative as well as preparation method, pharmaceutical composition and application thereof

A technology of bufalin and derivatives, applied in the field of medicinal chemistry, can solve the problems of insufficient patient selection, unsatisfactory pharmacological activity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

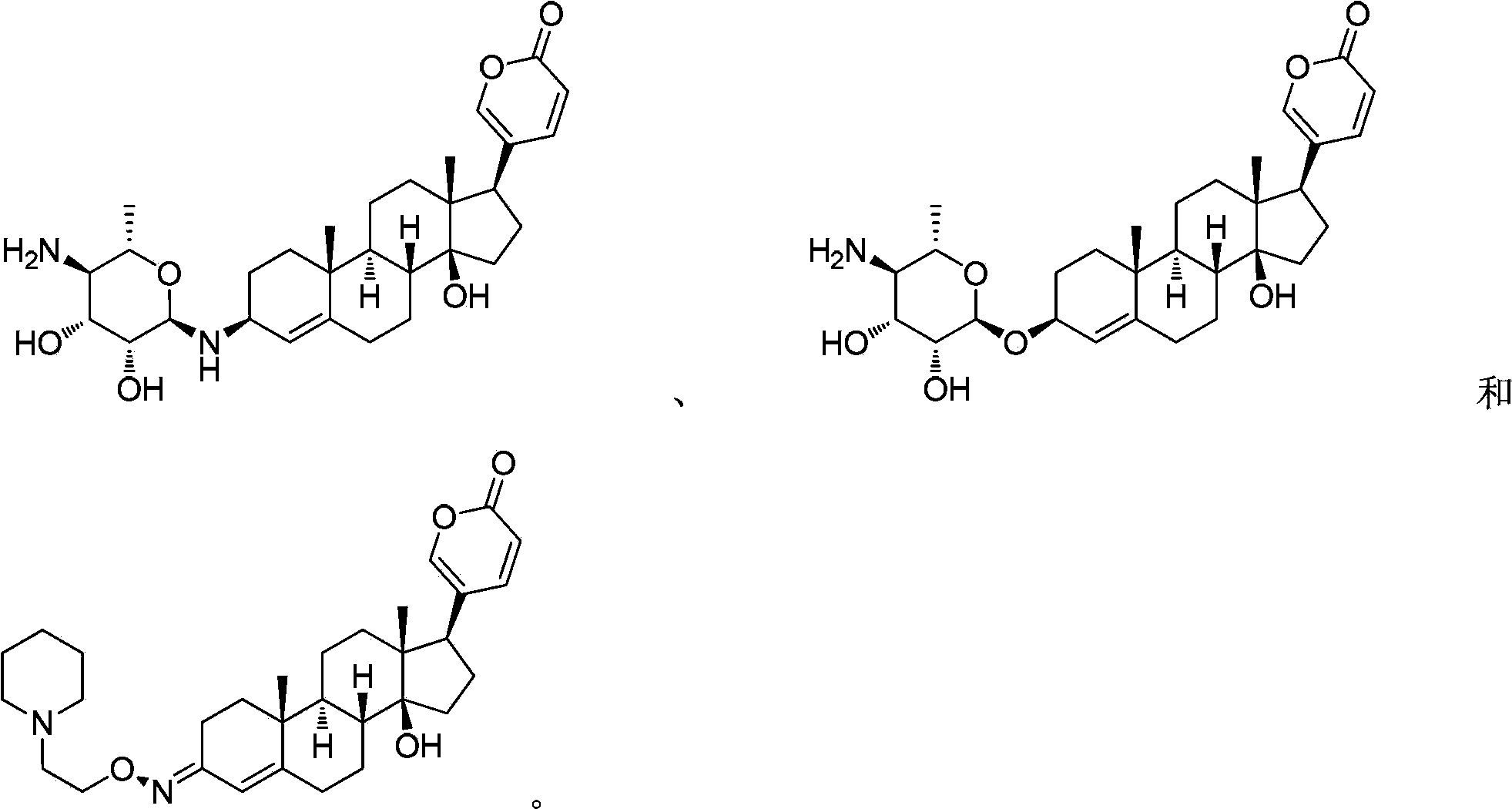

Method used

Image

Examples

Embodiment 01

[0096] Example 01: Preparation of Compound 2

[0097]

[0098] Under nitrogen protection, compound 1 (bufalin) (5 mmol) was dissolved in dichloromethane (DCM) (10 mL), and Rh(OAc) 2 (30mg, 0.1mol%), then slowly dropwise added a solution of methyl diazoacetate (25mmol) in dichloromethane (10mL), the solution was stirred at room temperature for 2 hours, quenched with anhydrous methanol, and the organic layer was washed with water (2×20mL) Twice, washed once with 20 mL of saturated saline, dried the dichloromethane layer over anhydrous sodium sulfate, removed the solvent under reduced pressure, and separated by column chromatography with petroleum ether / acetone=4:1 as the eluent to obtain Compound 2 in the form of white powder, the yield is 70%. 1 H NMR (400MHz, CDCl 3 )δ7.84(dd,J=9.7,2.4Hz,1H),7.21(s,1H),6.23(d,J=9.7Hz,1H),4.05(s,2H),3.72(s,3H), 3.69(s,1H),2.46-2.42(m,1H),2.23-1.07(m,23H),0.90(s,3H),0.67(s,3H);ESI-MS(m / z)459.3[M +1] + .

Embodiment 02

[0099] Example 02: Preparation of compound 3

[0100]

[0101] Compound 2 (3mmol) was dissolved in pyridine (10mL), and lithium iodide (LiI) (2g) was added, and the reaction solution was refluxed overnight at 110°C. After the reaction was completed, dichloromethane (10mL) was added, and then successively Wash once with 1N hydrochloric acid, water, and saturated saline with 20 mL each, dry the dichloromethane layer over anhydrous sodium sulfate, remove the solvent under reduced pressure, and perform column chromatography with petroleum ether / acetone = 3:2 as the eluent After separation, Compound 1 was obtained as a white powder with a yield of 80%. 1 H NMR (400MHz, CDCl 3 )δ7.84(dd,J=9.7,2.4Hz,1H),7.23(s,1H),6.27(d,J=9.7Hz,1H),4.07(s,2H),3.79(s,1H), 2.48-2.44(m,1H),2.23-1.07(m,23H),0.94(s,3H),0.70(s,3H);ESI-MS(m / z)445.3[M+1] + .

Embodiment 03

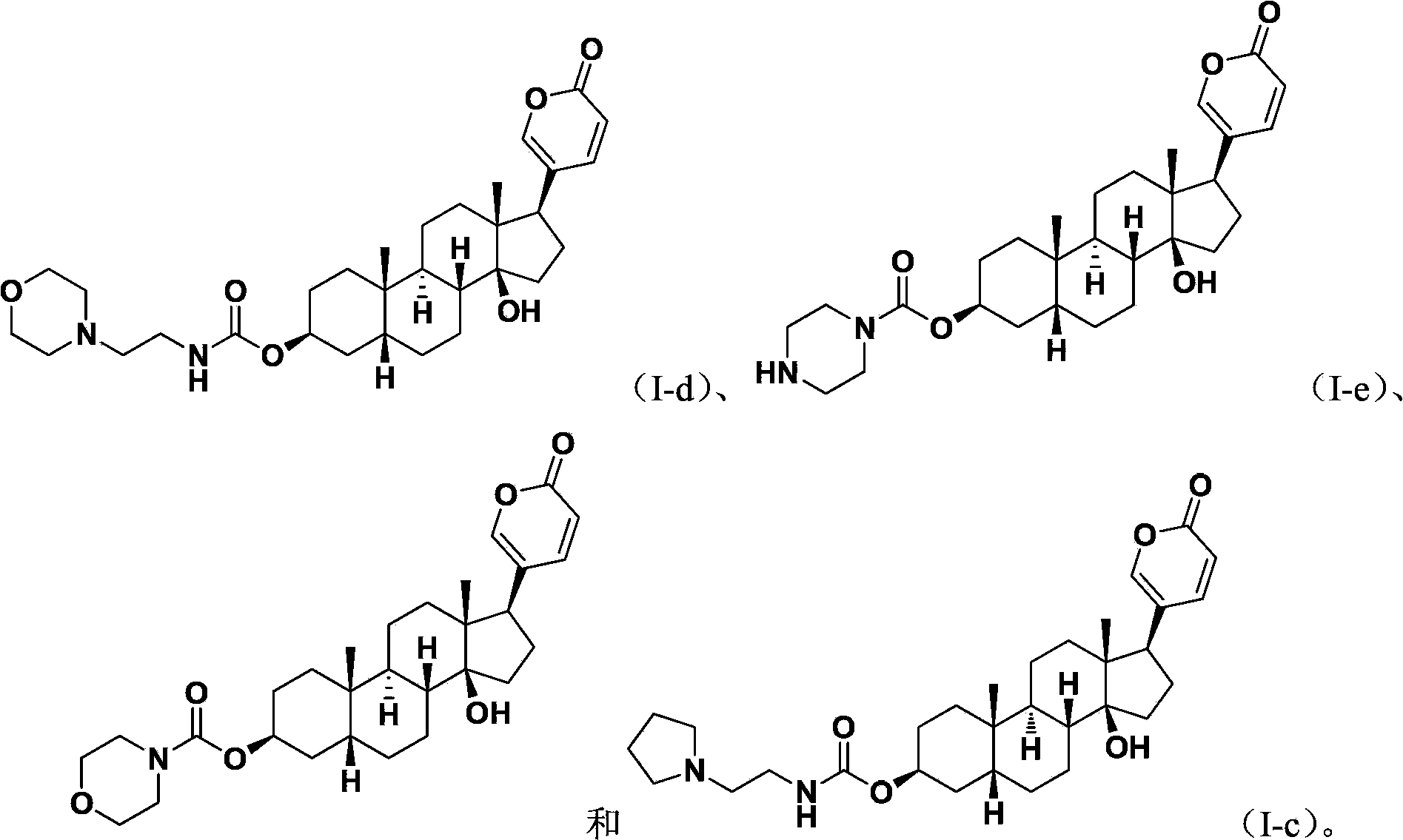

[0102] Example 03: Preparation of Compound A01

[0103]

[0104] In a 25 mL round bottom flask, compound 3 (1 mmol) was dissolved in 5 mL of dichloromethane, and 4-dimethylaminopyridine (DMAP) (0.5 mmol), piperazine (3 mmol), and 1-ethyl-( 3-Dimethylaminopropyl) carbodiimide hydrochloride (EDCI-HCl, 3mmol), stirred at room temperature overnight, after the reaction was completed, 20mL of dichloromethane was added, washed twice with water (2×20mL), Wash once with 20 mL of saturated saline, dry the dichloromethane layer over anhydrous sodium sulfate, remove the solvent under reduced pressure, and use petroleum ether / acetone = 2:1 as the eluent to separate by column chromatography to obtain a white powder The compound A01, yield 70%. 1 H NMR (400MHz, CDCl 3 )δ:7.84(dd,J=9.7,2.4Hz,1H),7.20(s,1H),6.23(d,J=9.7Hz,1H),4.10(s,2H),3.69(s,1H), 3.45(t,J=5.1Hz,4H),2.84(t,J=5.1Hz,4H),2.46(m,1H),2.23-1.07(m,23H),0.91(s,3H),0.67(s ,3H);ESI-MS(m / z)513.3[M+1] + .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com