Cerium oxide polishing powder and preparation method thereof

A technology of cerium oxide and polishing powder, which is applied in chemical instruments and methods, polishing compositions containing abrasives, inorganic chemistry, etc., can solve the problems of complex preparation process, high cost, complex production process, etc., and achieve high polishing precision, The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In 400kg pure water, add 100kg cerium carbonate (TREO is 45%, CeO 2 / TREO is 99.96%), slowly add hydrochloric acid under stirring conditions, until pH is 1.5, filter to obtain a clear and transparent aqueous solution of cerium chloride, then add 5kg of polyethylene glycol with a molecular weight of 3000 to obtain solution A;

[0044] Slowly add 5% sodium carbonate aqueous solution into solution A heated to 65°C until the pH is 6.5, and continue stirring for 4 hours after the addition.

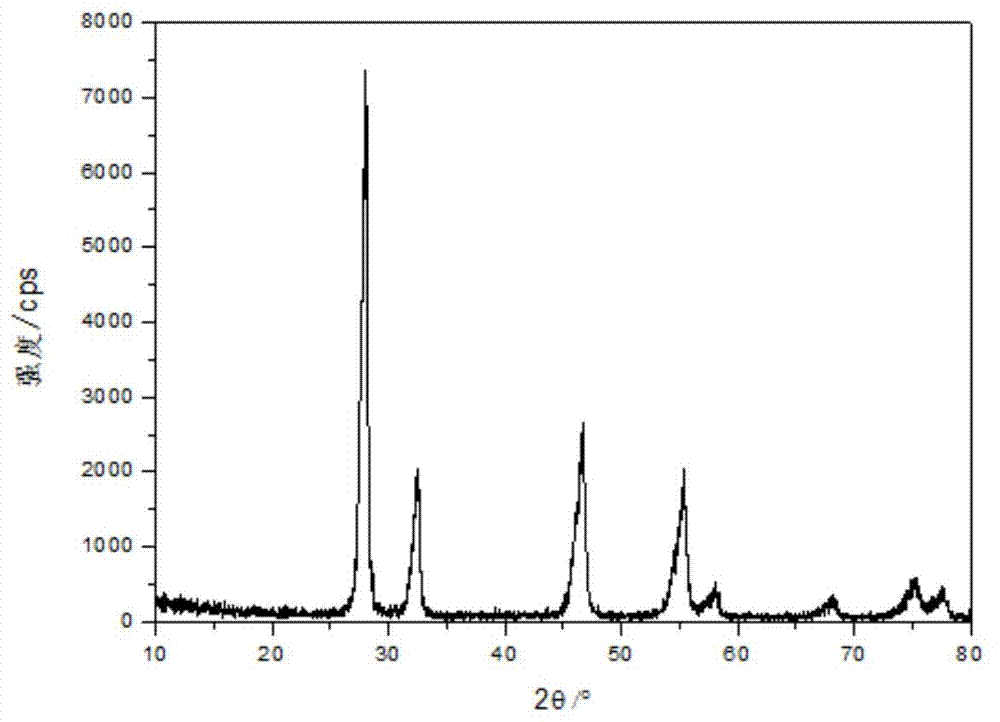

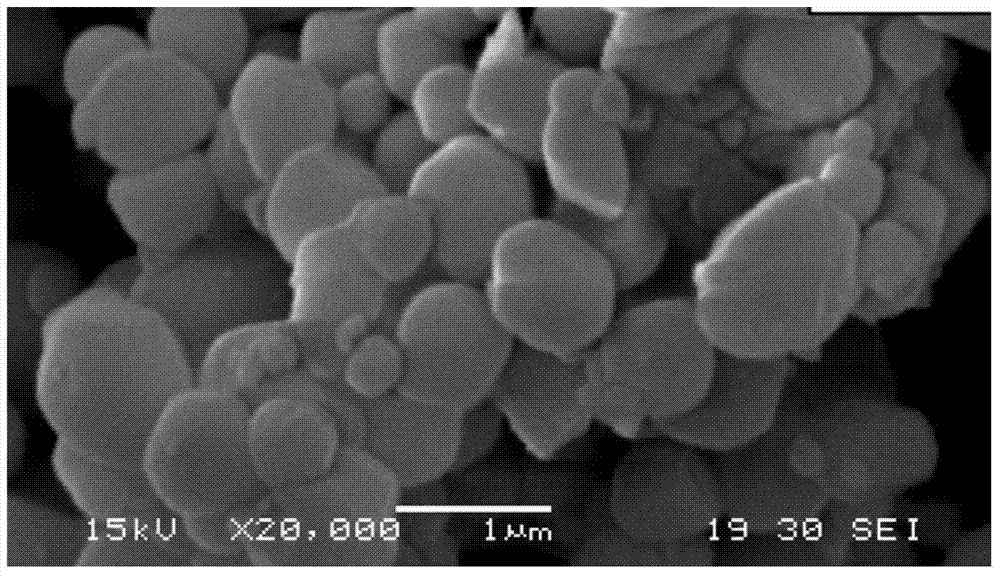

[0045] Then dehydrated by centrifugation and washed to Na 2 O≤400ppm, then calcined at 800° C. for 5 hours, and pulverized by air flow until D50 is 1.0 μm to obtain the rare earth polishing powder. figure 1 It is an XRD schematic diagram of the rare earth polishing powder obtained in Example 1 of the present invention. figure 2 SEM schematic diagram of the rare earth polishing powder obtained in Example 1 of the present invention.

Embodiment 2

[0047] In 234kg of pure water, add 100kg of cerium carbonate (TREO is 50%, CeO 2 / TREO is 99.99%), slowly add hydrochloric acid under agitation, until the pH is 2.5, filter to obtain a clear and transparent aqueous solution of lanthanum cerium chloride, then add 10kg of molecular weight polyethylene glycol to obtain solution A;

[0048] Slowly add 10% aqueous sodium carbonate solution into solution A heated to 85°C, and continue stirring for 2 hours after the addition. Then it was dehydrated by plate and frame filter press, calcined at 1000°C for 3 hours, and pulverized by air flow until D50 was 2.0 μm to obtain the rare earth polishing powder.

Embodiment 3

[0050] In 400kg pure water, add 100kg cerium carbonate (TREO is 45%, CeO 2 / TREO is 99.98%), slowly add hydrochloric acid under stirring conditions, until the pH is 2.0, filter to obtain a clear and transparent aqueous solution of cerium chloride, and then add 7kg of polyethylene glycol with a molecular weight of 6000 to obtain solution A.

[0051] Slowly add 7% sodium carbonate aqueous solution into solution A heated to 65°C until the pH is 7.0, and continue stirring for 4 hours after the addition.

[0052] Then dehydrated by centrifugation and washed to Na 2 O≤400ppm, then calcined at 900° C. for 4 hours, and pulverized by air flow until D50 is 1.5 μm to obtain the rare earth polishing powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com