Method for processing polyester staple fibers special for vortex spinning

A technology of polyester staple fiber and processing method, which is applied in the direction of one-component copolyester rayon and other directions to achieve the effects of stable production operation, lower knot failure rate and lower modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

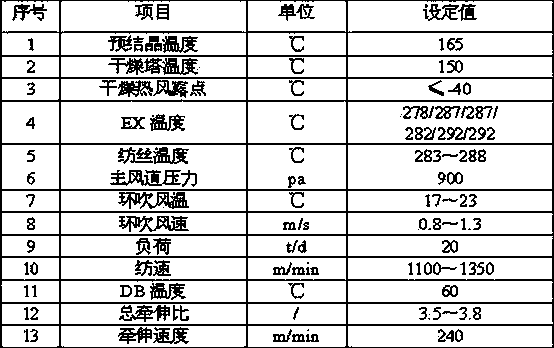

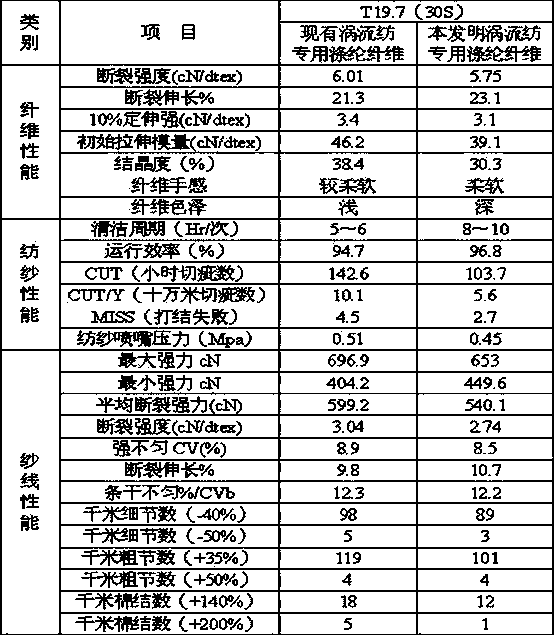

Method used

Image

Examples

Embodiment 1

[0022] On the 300L polymerization device, add PTA, IPA and EG into the polymerization kettle, the molar ratio of dibasic acid to dibasic alcohol is 1:1.39, the amount of IPA added is 1% (mass percentage) of the amount of PTA, and ethylene glycol is used Antimony as a catalyst. The direct esterification reaction is carried out at 270-280°C, the by-product water and the remaining EG are distilled off, and the esterification reaction is completed in 2-3 hours. Start vacuuming to heat up. The polycondensation reaction is carried out at a vacuum degree of less than 100Pa and at a temperature of 270-280°C. 3 ~ 4hr polycondensation reaction ends. Control the intrinsic viscosity of the copolyester at 0.65±0.03 dl / g. The general properties of copolyesters are shown in Table 1.

Embodiment 2

[0024] On the 300L polymerization device, add PTA, IPA and EG into the polymerization kettle, the molar ratio of dibasic acid to dibasic alcohol is 1:1.39, the amount of IPA added is 2% (mass percentage) of the amount of PTA, and ethylene glycol is used Antimony as a catalyst. The direct esterification reaction is carried out at 270-280°C, the by-product water and the remaining EG are distilled off, and the esterification reaction is completed in 2-3 hours. Start vacuuming to heat up. The polycondensation reaction is carried out at a vacuum degree of less than 100Pa and at a temperature of 270-280°C. 3 ~ 4hr polycondensation reaction ends. Control the intrinsic viscosity of the copolyester at 0.65±0.03 dl / g. The general properties of copolyesters are shown in Table 1.

Embodiment 3

[0026] On the 300L polymerization device, add PTA, IPA and EG into the polymerization tank, the molar ratio of dibasic acid to dibasic alcohol is 1:1.39, the amount of IPA added is 3% (mass percentage) of the amount of PTA, and ethylene glycol is used Antimony as a catalyst. The direct esterification reaction is carried out at 270-280°C, the by-product water and the remaining EG are distilled off, and the esterification reaction is completed in 2-3 hours. Start vacuuming to heat up. The polycondensation reaction is carried out at a vacuum degree of less than 100Pa and at a temperature of 270-280°C. 3 ~ 4hr polycondensation reaction ends. Control the intrinsic viscosity of the copolyester at 0.65±0.03 dl / g. The general properties of copolyesters are shown in Table 1.

[0027] Table 1 General properties of copolyester chips.

[0028] Sample serial number Example 1 Example 2 Example 3 [COOH] (mol / t) 17.17 19.6 19.36 η (dl / g) 0.643 0.653 0.661 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com