Silica-supported lithium phosphate catalyst in eggshell shape, and preparation method and application thereof

A technology for supporting catalysts and silica, which is applied in the field of preparation of inorganic non-metallic catalytic materials and catalytic applications, and can solve the problems of low conversion rate of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

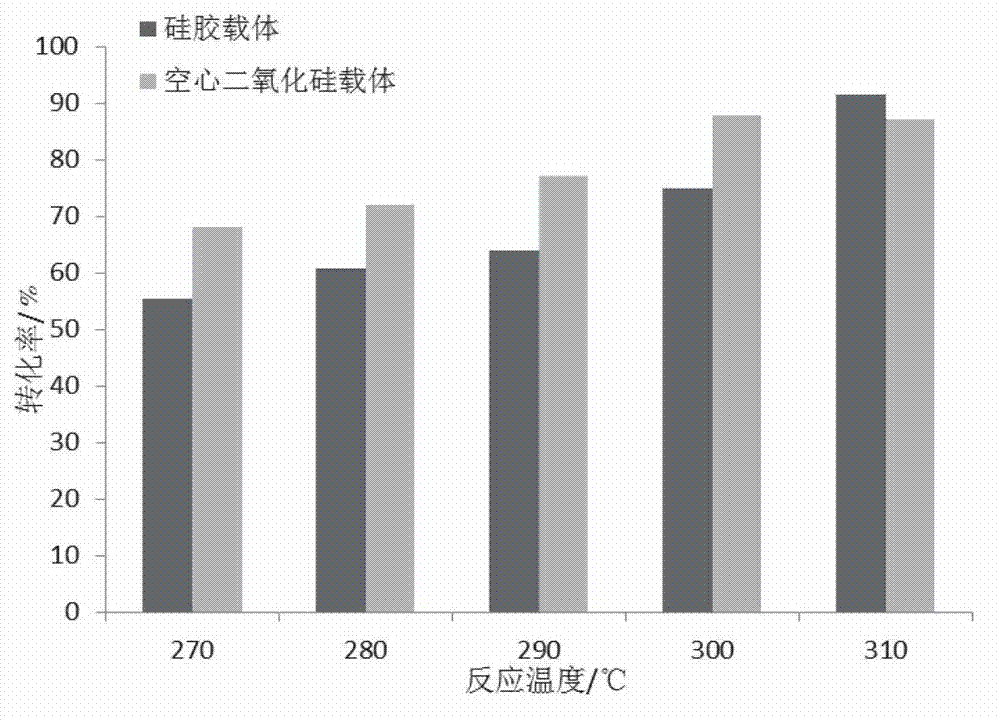

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

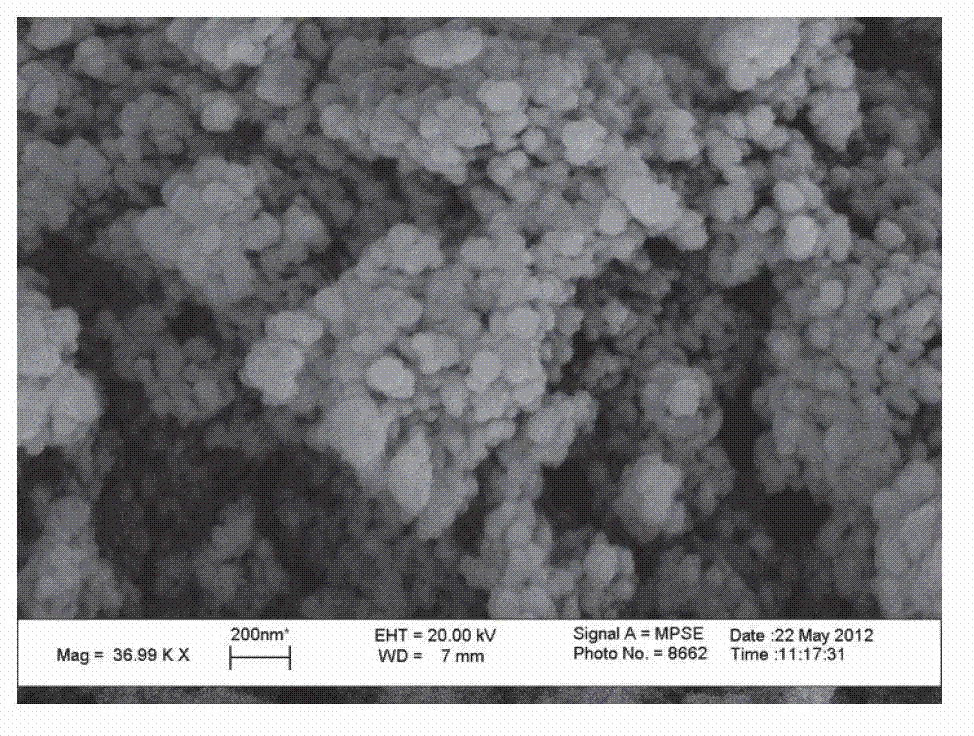

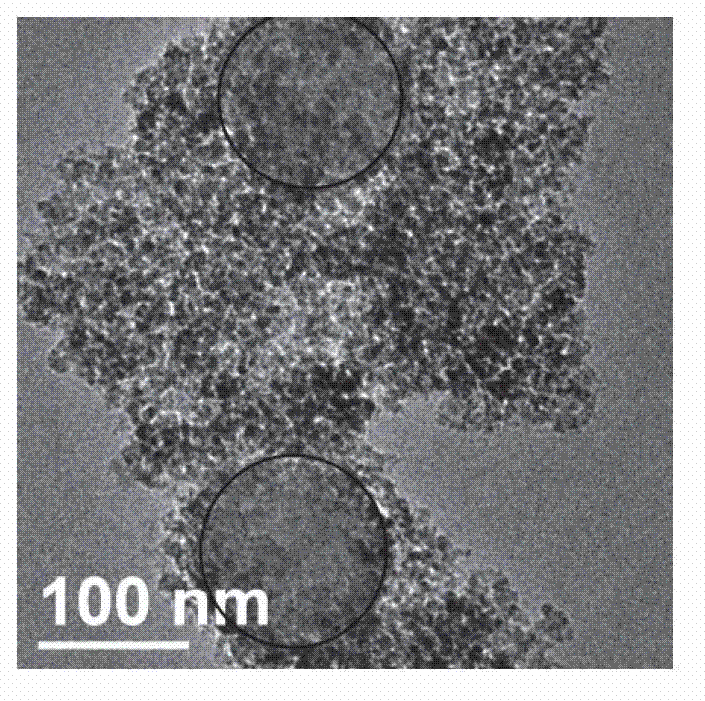

[0025] Preparation of hollow nano-silica microspheres:

[0026] Add 45mL of distilled water, 5mL of styrene, and 0.75g of polyvinylpyrrolidone into a 100mL three-neck flask, stir well at room temperature for 30min, control the temperature at 60°C, stir at a constant temperature, and add 12mL of an aqueous initiator solution (containing 0.2g of ammonium persulfate) dropwise. , and continued to react for 9h to obtain a polystyrene emulsion sample.

[0027] Add 3mL polystyrene emulsion, 0.6mL ammonia water (25% concentrated ammonia water), absolute ethanol and distilled water into a 100mL three-necked flask, and stir at room temperature for 30min. 5mL tetraethyl orthosilicate solution was added dropwise, and the reaction was continued for 12h. Aging at room temperature for 24 hours, centrifuged, washed three times with absolute ethanol, air-dried at 80°C for 8 hours, and placed in a muffle furnace for calcination at 800°C for 4 hours to obtain white SiO 2 nanospheres.

[0028]...

Embodiment 2

[0034] Potassium hydroxide was used to replace sodium hydroxide in the preparation process of alkaline lithium phosphate, and the remaining process conditions were the same as in Example 1.

Embodiment 3

[0036] Preparation of hollow nano-silica microspheres:

[0037] Add 45mL of distilled water, 5mL of styrene, and 0.75g of polyvinylpyrrolidone into a 100mL three-necked flask, stir well at room temperature for 30min, control the temperature at 90°C, stir at a constant temperature, and add 12mL of an aqueous initiator solution (containing 0.2g of ammonium persulfate) dropwise. , and continue to react for 10h to prepare a polystyrene emulsion sample.

[0038] Add 3mL polystyrene emulsion, 0.6mL ammonia water (25% concentrated ammonia water), absolute ethanol and distilled water into a 100mL three-necked flask, and stir at room temperature for 30min. 5mL tetraethyl orthosilicate solution was added dropwise, and the reaction was continued for 12h. Aging at room temperature for 24 hours, centrifuged, washed three times with absolute ethanol, air-dried at 80°C for 8 hours, and placed in a muffle furnace for calcination at 300°C for 4 hours to obtain white SiO 2 nanospheres.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com