A kind of preparation technology of polyphenylene sulfide grinding disc for papermaking

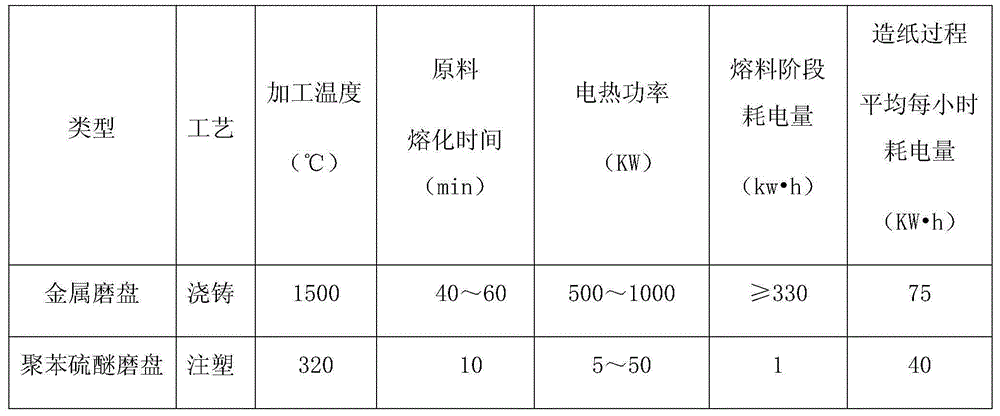

A technology of polyphenylene sulfide and preparation process, which is applied in the field of material engineering, can solve the problems of insignificant improvement of pulp physical properties, reduce the service life of engineering plastic grinding discs, and cannot solve the thermal stability of materials, so as to achieve the effect of fiber separation Large, saving power consumption, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

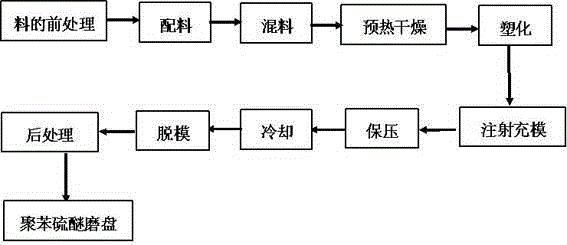

[0021] Example 1: A preparation process of polyphenylene sulfide grinding discs for papermaking, the polyphenylene sulfide grinding discs are made of polyphenylene sulfide composite materials, and the polyphenylene sulfide composite materials include the following raw materials: polyphenylene sulfide Resin, toughening component, reinforcing fiber, wear-resistant component, the preparation process includes the following steps:

[0022] S1. Pretreatment of materials: surface modification of toughening components, reinforcing fibers, and wear-resistant components; toughening components are one or more of polyamide resins, polyester resins, and polyacrylic resins; reinforced The fiber is one or more of glass fiber, carbon fiber, and aramid fiber; the wear-resistant component is one or more of polytetrafluoroethylene, graphite, and molybdenum disulfide;

[0023] S2. Ingredients and mixing: Weigh each raw material according to the formula ratio, and fully mix the prepared raw materi...

Embodiment 2

[0030] Example 2: A preparation process of polyphenylene sulfide grinding discs for papermaking, the polyphenylene sulfide grinding discs are made of polyphenylene sulfide composite materials, and the polyphenylene sulfide composite materials include the following raw materials: polyphenylene sulfide Resin, toughening component, reinforcing fiber, wear-resistant component, the preparation process includes the following steps:

[0031] S1. Pretreatment of materials: surface modification of toughening components, reinforcing fibers, and wear-resistant components; toughening components are one or more of polyamide resins, polyester resins, and polyacrylic resins; reinforced The fiber is one or more of glass fiber, carbon fiber, and aramid fiber; the wear-resistant component is one or more of polytetrafluoroethylene, graphite, and molybdenum disulfide;

[0032] S2. Batching and mixing: Weigh each raw material according to the formula ratio, and fully mix the prepared raw materials...

Embodiment 3

[0039] Example 3: A preparation process of polyphenylene sulfide grinding discs for papermaking. The polyphenylene sulfide grinding discs are made of polyphenylene sulfide composite materials, and the polyphenylene sulfide composite materials include the following raw materials: polyphenylene sulfide Resin, toughening component, reinforcing fiber, wear-resistant component, the preparation process includes the following steps:

[0040] S1. Pretreatment of materials: surface modification of toughening components, reinforcing fibers, and wear-resistant components; toughening components are one or more of polyamide resins, polyester resins, and polyacrylic resins; reinforced The fiber is one or more of glass fiber, carbon fiber, and aramid fiber; the wear-resistant component is one or more of polytetrafluoroethylene, graphite, and molybdenum disulfide;

[0041] S2. Ingredients and mixing: Weigh each raw material according to the formula ratio, and fully mix the prepared raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com