Method for preparing refining agent from dechlorinated light salt brine

A technology of brackish water and refined preparations, applied in chemical instruments and methods, preparation of alkali metal sulfites, alkali metal carbonates, etc., can solve problems such as unfavorable brine concentration, stabilization of unfavorable brine concentration, clogging of pipelines, etc. Achieve the effect of overcoming the decrease in salt water concentration, accelerating the dissolution rate, and being beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

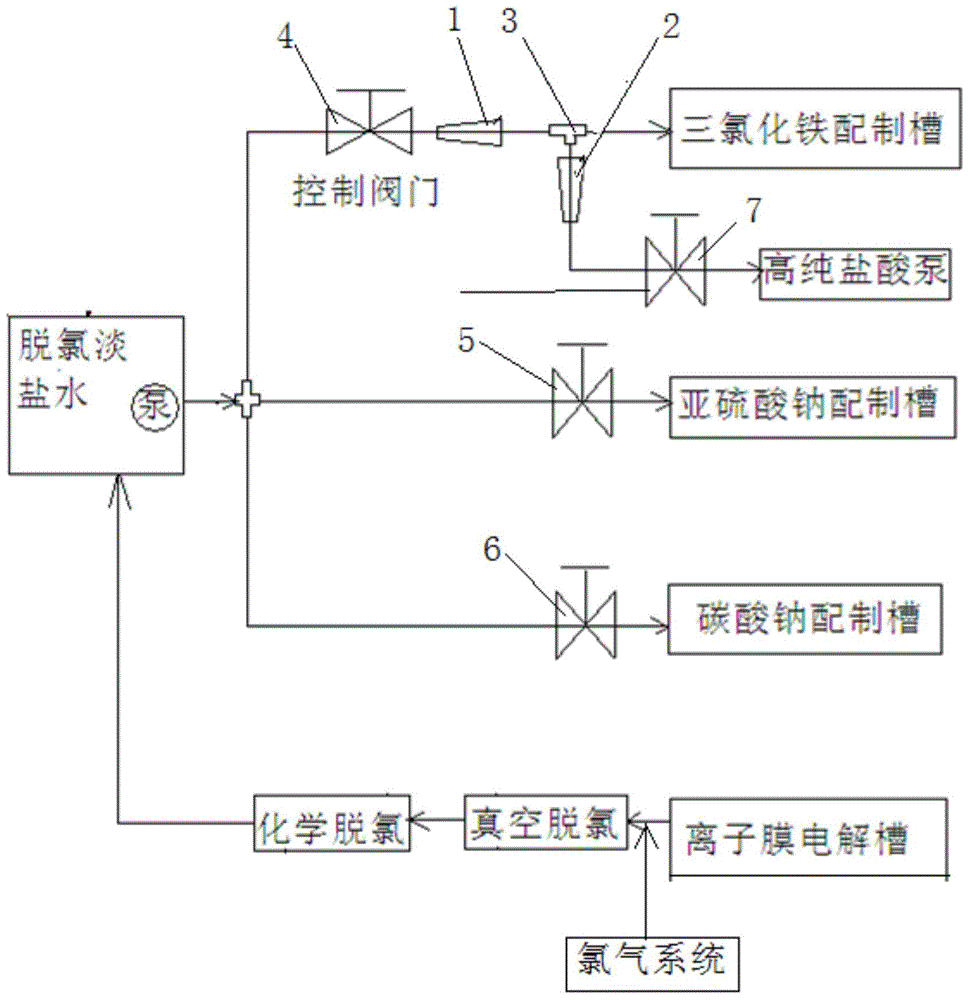

[0014] The technical scheme of the present invention will be described below according to the accompanying drawings.

[0015] Such as figure 1 In the shown chlor-alkali production, the process method utilizing chlorinated light brine,

[0016] The first step: first set up a light brine container, install a brine pump in the light brine container, and lay brine pipelines from the brine pump to the sodium sulfite preparation tank, sodium carbonate preparation tank and ferric chloride preparation tank respectively; A first control valve 4 is arranged on the brine pipeline before the tank laying, and a first rotameter 1 is arranged on the brine pipeline between the first control valve 4 and the ferric chloride preparation tank; the brine pipeline before the sodium sulfite preparation tank The second control valve 5 is provided on the top; the third control valve 6 is provided on the brine pipeline before the sodium carbonate preparation tank;

[0017] Step 2: Lay the hydrochlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com