Multi-stage high-efficiency low-nitrogen combustion method and combustion system for circulating fluidized bed boiler

A circulating fluidized bed, low-nitrogen combustion technology, which is applied in the direction of fluidized bed combustion equipment, combustion methods, fuels burned in a molten state, etc., can solve the problem of increasing thermal nitrogen oxides, affecting the full combustion of fuel, slagging and high temperature Corrosion increases and other problems, to achieve the effect of reducing the formation of fuel-type nitrogen oxides and thermal nitrogen oxides, reducing the tendency of slagging and high-temperature corrosion in the furnace, and inhibiting the formation of thermal nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

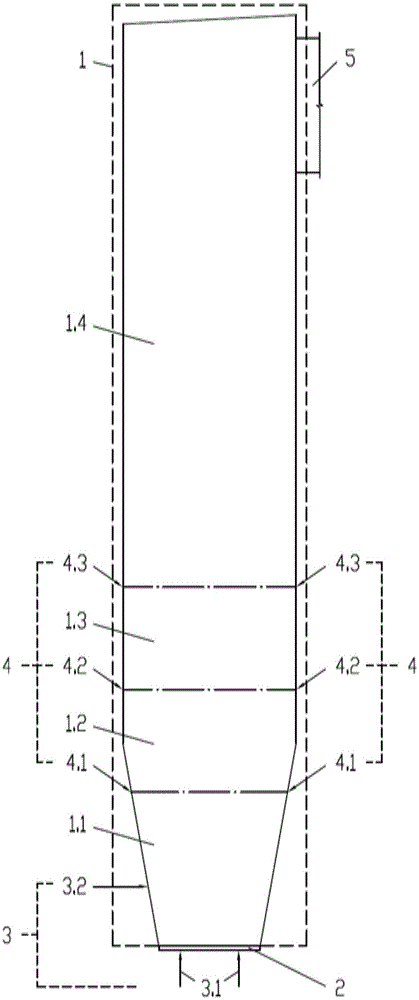

[0025] A high temperature circulating fluidized bed boiler, multi-stage high-efficiency low-nitrogen combustion system includes furnace, air distribution board, primary air inlet and secondary air inlet. The furnace is divided into oxygen-deficient combustion zone, reduction zone, oxidation zone from bottom to top. In the combustion zone and burnout zone, the upper boundary of the oxygen-deficient combustion zone is 4.5 meters away from the surface of the air distribution plate, the upper boundary of the reduction zone is 7.5 meters away from the surface of the air distribution plate, and the upper boundary of the oxidative combustion zone is 9.5 meters away from the surface of the air distribution plate. The exhaustion zone is located above the upper boundary of the oxidative combustion zone. A bottom primary air inlet is arranged under the air distribution plate, a layer of reduction air inlet is arranged on the front and rear walls of the furnace in the reduction zone, and a...

Embodiment 2

[0034] In this example, in a medium-temperature circulating fluidized bed boiler, the combustion air in the furnace is classified in depth as a whole, and in the height direction of the furnace, according to the combustion characteristics of the fuel, the furnace is divided into oxygen-deficient from bottom to top. combustion zone, reduction zone, oxidative combustion zone and burnout zone.

[0035] The combustion of the fuel in the furnace and the generation and reduction process of nitrogen oxides are basically the same as the embodiment 1, and the difference between the two is:

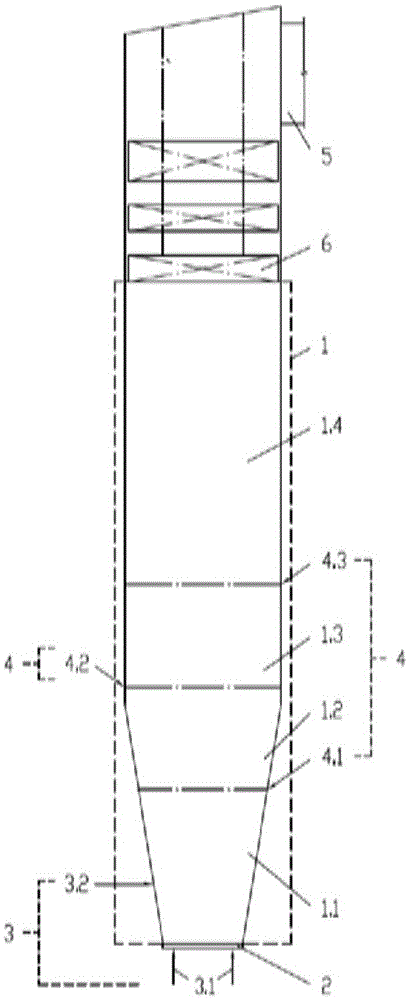

[0036] In this embodiment, in order to ensure the efficient combustion of the fuel, the height value between the burnout air inlet of the uppermost layer and the first row of pipes on the first group of convection heating surfaces in the upper part of the furnace is set as the average velocity value of the flue gas in the burnout zone. 2.5 times.

[0037] In this embodiment, only one layer of redu...

Embodiment 3

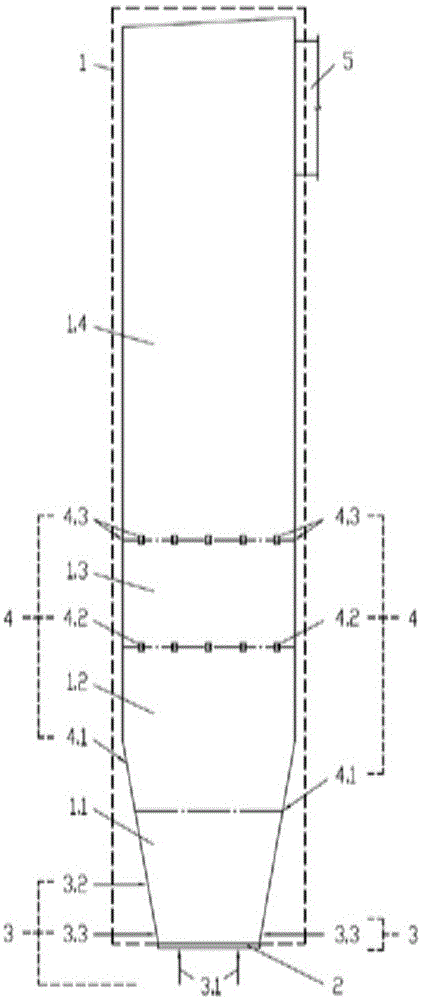

[0040] The overall layout, the combustion of fuel in the furnace, and the generation and reduction process of nitrogen oxides in this embodiment are basically the same as those in Embodiment 1. The differences between the two are:

[0041] In this embodiment, an annular primary air inlet is provided on the furnace wall near the upper part of the air distribution plate.

[0042] In this embodiment, the secondary air enters the furnace in four layers, which are two layers of reducing air, one layer of oxidizing air and one layer of exhaust air. Among them, the vents of the lower reducing air are located on the back wall of the furnace, the vents of the upper reducing air are located on the front wall of the furnace; the vents of the oxidizing air are located on the walls on both sides of the furnace; the vents of the exhausted air are located on the four walls of the furnace.

[0043] In this embodiment, the excess air coefficient of the oxygen-deficient combustion zone is contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com