Manufacturing process of pressure sensor sensitive element

A pressure sensor and sensitive element technology, applied in electrical components, electric solid state devices, semiconductor devices, etc., to increase long-term stability, improve signal linearity, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

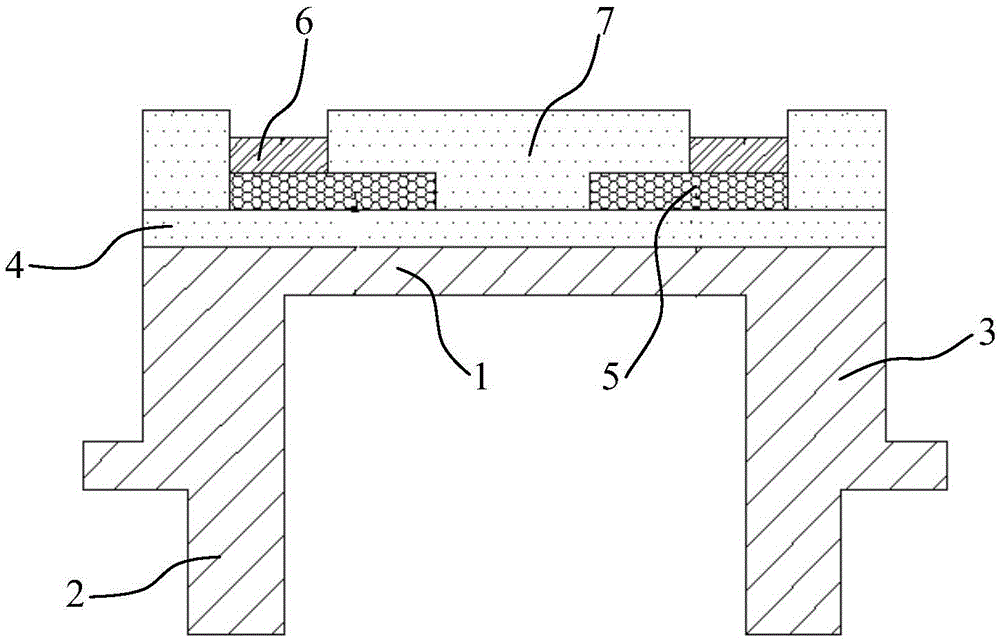

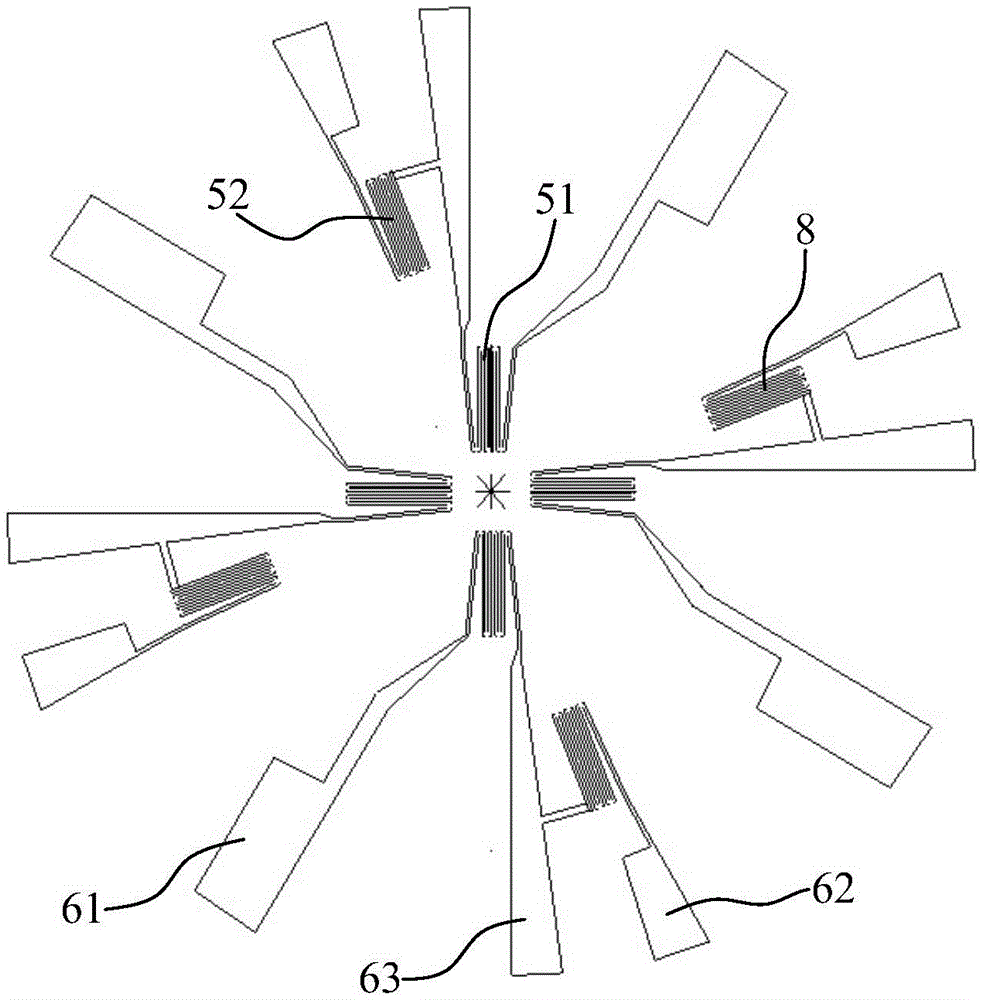

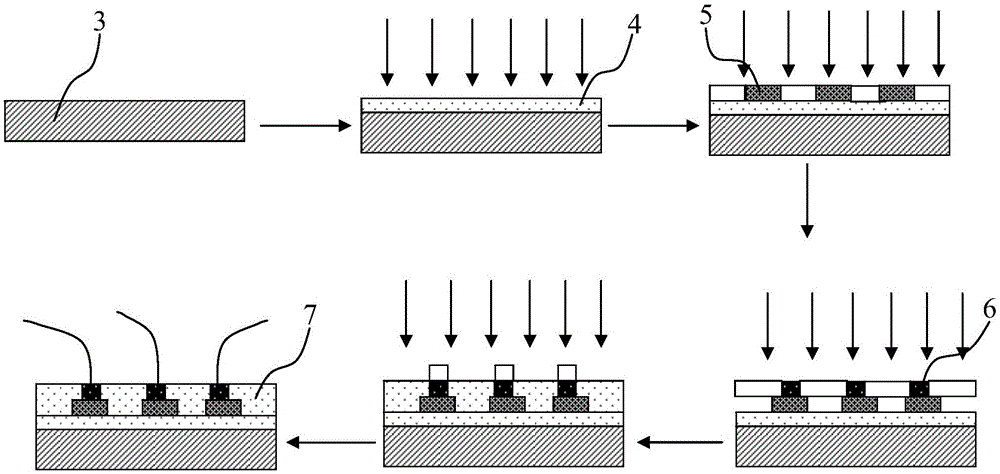

[0029] Embodiment: A manufacturing process of a pressure sensor sensitive element, the pressure sensor sensitive element includes a cup-shaped substrate 3 composed of a circular base layer 1 and an annular side plate 2 located in the circumferential direction of the circular base layer 1, located in the circular Form the silicon dioxide spacer layer 4 on the upper surface of the base layer 1, and the surface of the silicon dioxide spacer layer 4 opposite to the circular base layer 1 is provided with at least four boron-doped P-type microcrystalline silicon strips 5, and a metal electrode layer 6 Located on the surface opposite to the boron-doped P-type microcrystalline silicon strip 5 and the silicon dioxide isolation layer 4, the boron-doped P-type microcrystalline silicon strip 5 is filled with a silicon dioxide insulating layer 7; the at least four doped The boron P-type microcrystalline silicon strip 5 includes at least 2 first boron-doped P-type microcrystalline silicon st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com