Self-adhesion hemostasis anti-adhesion corpus fibrosum

A fibrous and anti-adhesion technology, applied in the fields of medical science, bandages, absorbent pads, etc., can solve the problem of unresolved metabolism of hemostatic agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

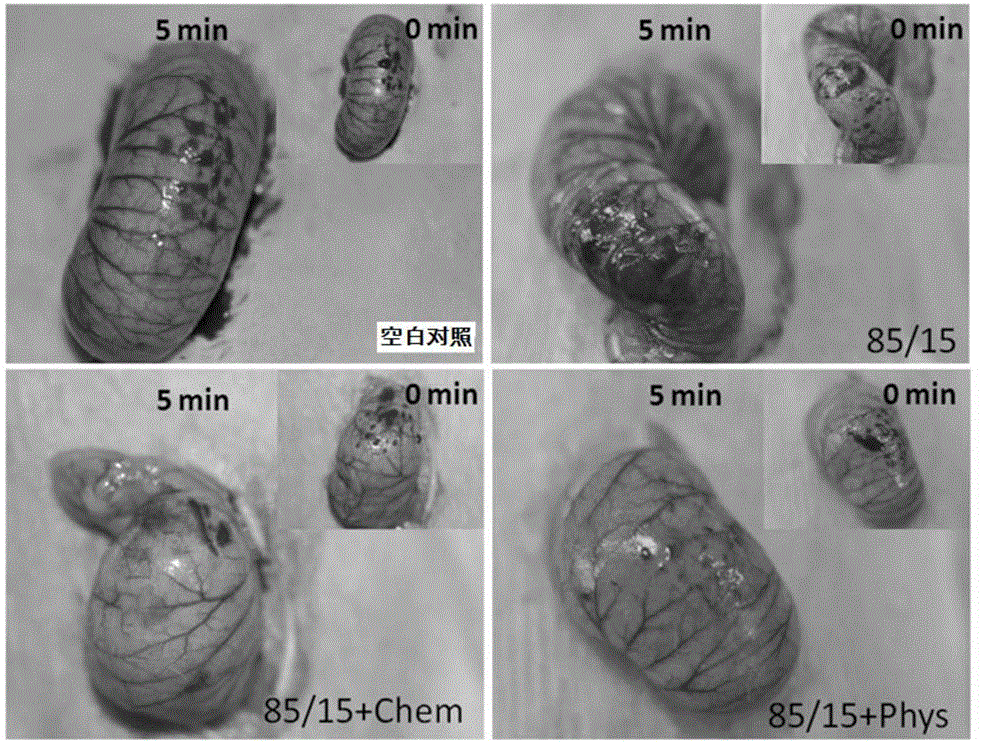

Image

Examples

Embodiment 1

[0036] In this embodiment, the anti-adhesion fiber body with self-adhesive and hemostatic function is prepared according to the following method:

[0037] (1) Prepare organic polymer mixed solution: dissolve PLGA (Mw=80,000, LA / GA=75 / 25) in DMF / acetone mixed solvent (DMF / acetone volume ratio 1 / 1), and prepare a concentration of 30 % (W / V) organic polymer mixed solution, stirred at room temperature for 12 hours.

[0038] (2) Preparation of anti-adhesion fiber material: Inject the organic polymer mixed solution prepared in step (1) into ten 10mL syringes respectively, add a No. 5 stainless steel needle, at a voltage of 25KV, and a solution flow rate of 1.5mL / h, Under the condition that the receiving distance is 18 cm, multi-nozzle electrospinning is carried out for 40 minutes to obtain a composite fiber material, which is vacuum-dried at room temperature for 24-48 hours to remove residual solvent, and the thickness of the fiber membrane material is 100-140 microns.

[0039] (3)...

Embodiment 2

[0042] In this embodiment, the anti-adhesion fiber body with self-adhesive and hemostatic function is prepared according to the following method:

[0043] (1) Preparation of organic polymer mixed solution: Dissolve PLA (Mw=50,000) in DMF / acetone mixed solvent (DMF / acetone volume ratio 1 / 1), and prepare an organic polymer solution with a concentration of 20% (W / V). The polymer mixed solution was stirred at room temperature for 8 hours.

[0044] (2) Preparation of anti-adhesion fiber material: Inject the organic polymer mixed solution prepared in step (1) into ten 10mL syringes, add a No. 5 stainless steel needle, and receive Under the condition of a distance of 25 cm, multi-nozzle electrospinning was carried out for 40 minutes to obtain a composite fiber material, which was vacuum-dried at room temperature for 24 hours to remove residual solvent, and the thickness of the fiber membrane material was 100-120 microns.

[0045] (3) Preparation of hemostatic material solution: Diss...

Embodiment 3

[0048] In this embodiment, the anti-adhesion fiber body with self-adhesive and hemostatic function is prepared according to the following method:

[0049] (1) Prepare organic polymer mixed solution: dissolve PGCL (Mw=500,000, CL / GA=75 / 25) in DMF / acetone mixed solvent (DMF / acetone volume ratio 1 / 1), and prepare a concentration of 50 % (W / V) organic polymer mixed solution, stirred at room temperature for 15 hours.

[0050] (2) Preparation of anti-adhesion fiber material: Inject the organic polymer mixed solution prepared in step (1) into ten 10mL syringes respectively, add a No. 5 stainless steel needle, at a voltage of 30KV, and a solution flow rate of 1mL / h, receive Under the condition of a distance of 5 cm, multi-nozzle electrospinning was performed for 60 minutes to obtain a composite fiber material, which was vacuum-dried at room temperature for 48 hours to remove residual solvent, and the thickness of the fiber membrane material was 150-180 microns.

[0051] (3) Preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com