Preparation method of nano-bone scaffold composite material

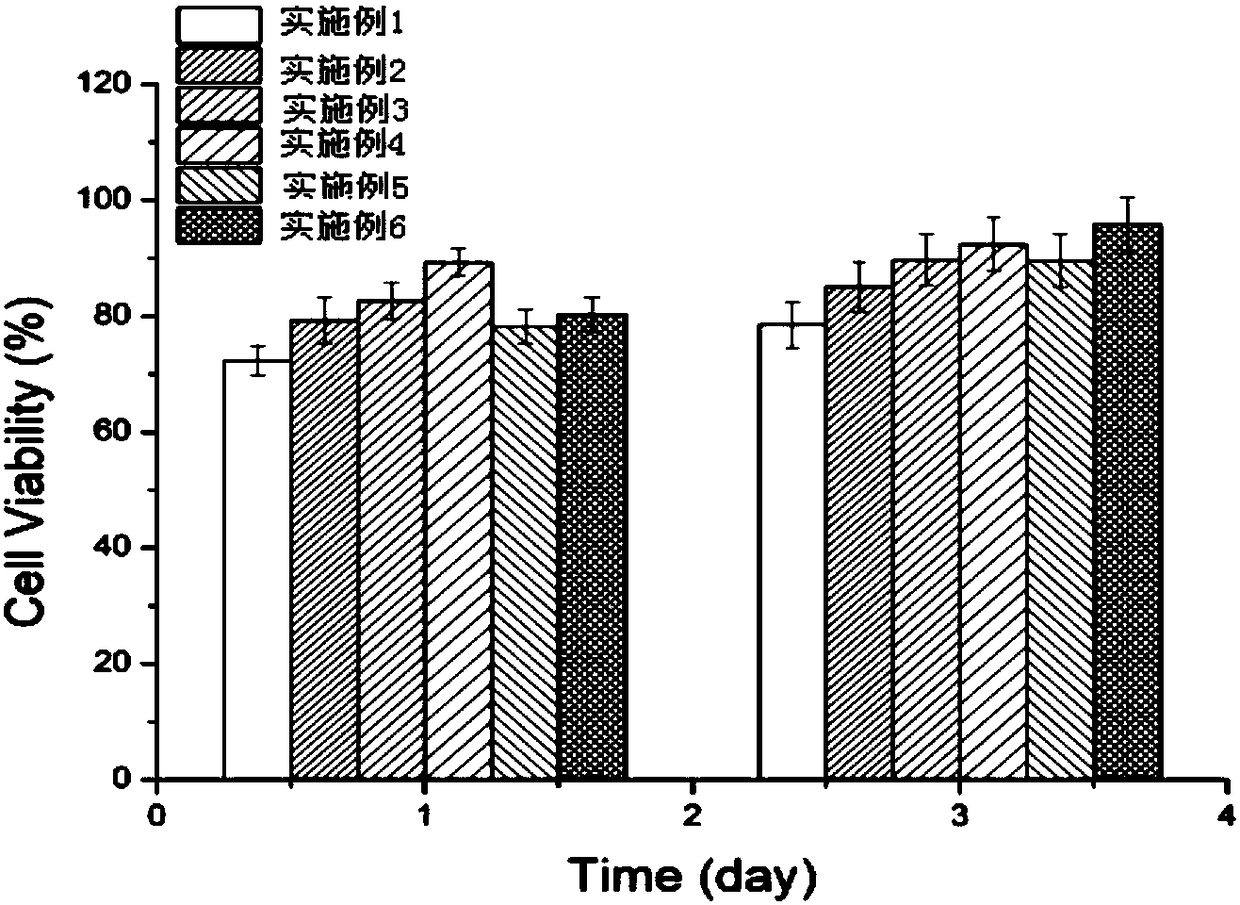

A composite material and bone scaffold technology, applied in the field of biomedical materials, can solve the problems of limitations, low activity of bone scaffolds, difficult to control mechanical properties, etc., achieve low cost, improve physicochemical properties and biological properties, and improve cell compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of nano-bone scaffold composite material, comprising the steps of:

[0024] (1) Preparation of biphasic calcium phosphate nanopowder: 0.4M Ca(NO 3 ) 2 4H 2 O solution and 0.2M (NH 4 ) 2 HPO 4 The solution was added into a three-necked flask according to the calcium-phosphorus molar ratio of 1.65:1, stirred and mixed evenly, and then the pH was adjusted to 11 with 25% ammonia water to obtain a white powder precipitate. After filtering, the white powder was washed with deionized water. Then dry it at 100°C, put it into a muffle furnace for roasting, first raise the temperature to 1125°C at a rate of 10°C / min, keep it for 1 hour, then lower it to room temperature with the furnace, then take it out and grind it, and finally pass it through a 200-mesh sieve to obtain a two-phase Calcium phosphate nanopowder;

[0025] (2) prepare hydroxyethyl chitosan: get 10g chitosan and join in the 50wt% sodium hydroxide solution of 16.7g and carry out alkalizati...

Embodiment 2

[0029] A preparation method of nano-bone scaffold composite material, comprising the steps of:

[0030] (1) Preparation of biphasic calcium phosphate nanopowder: 0.4M Ca(NO 3 ) 2 4H 2 O solution and 0.2M (NH 4 ) 2 HPO 4 The solution was added into a three-necked flask according to the calcium-phosphorus molar ratio of 1.60:1, stirred and mixed evenly, and then the pH was adjusted to 11 with 25% ammonia water to obtain a white powder precipitate. After filtering, the white powder was washed with deionized water. Then dry it at 100°C, put it into a muffle furnace for roasting, first raise the temperature to 1125°C at a rate of 10°C / min, keep it for 1 hour, then lower it to room temperature with the furnace, then take it out and grind it, and finally pass it through a 200-mesh sieve to obtain a two-phase Sodium Phosphate

[0031] rice powder;

[0032] (2) prepare hydroxyethyl chitosan: get 10g chitosan and join in the 50wt% sodium hydroxide solution of 16.7g and carry out ...

Embodiment 3

[0036] A preparation method of nano-bone scaffold composite material, comprising the steps of:

[0037] (1) Preparation of biphasic calcium phosphate nanopowder: 0.4M Ca(NO 3 ) 2 4H 2 O solution and 0.2M (NH 4 ) 2 HPO 4 The solution was added into a three-necked flask according to the calcium-phosphorus molar ratio of 1.55:1, stirred and mixed evenly, and then the pH was adjusted to 11 with 25% ammonia water to obtain a white powder precipitate. After filtering, the white powder was washed with deionized water. Then dry it at 100°C, put it into a muffle furnace for roasting, first raise the temperature to 1125°C at a rate of 10°C / min, keep it for 1 hour, then lower it to room temperature with the furnace, then take it out and grind it, and finally pass it through a 200-mesh sieve to obtain a two-phase Calcium phosphate nanopowder;

[0038] (2) prepare hydroxyethyl chitosan: get 10g chitosan and join in the 50wt% sodium hydroxide solution of 16.7g and carry out alkalizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com