Manganese-silicon high-chromium cast iron and preparation method thereof

A technology of high-chromium cast iron and manganese-silicon, applied in the field of wear-resistant metal materials, can solve the problems of unsatisfactory mechanical properties, complex production process, and unstable performance of high-chromium cast iron, so as to improve hardenability, simple process, and reasonable ingredients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

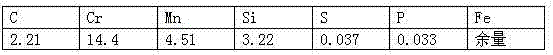

[0027] The chemical composition of manganese silicon high chromium cast iron is as shown in table 1 by weight percentage:

[0028] Table 1 Manganese silicon high chromium cast iron composition and content (wt%)

[0029]

[0030] 1.1. Raw material selection

[0031] In percent by weight, steel scrap, pig iron, ferrochrome, ferromanganese and ferrosilicon are batched according to the composition requirements of Table 1;

[0032] 1.2. Bake ferrochromium, ferromanganese and ferrosilicon to remove moisture and surface oil stains of ferrochromium, ferromanganese and ferrosilicon; put scrap steel and pig iron into induction furnace for melting, then perform pre-deoxidation operation , and then add baked ferrochromium, ferromanganese and ferrosilicon to obtain molten iron;

[0033] 1.3, take molten iron sample and carry out pre-stove analysis, according to analysis result, adjust described molten iron composition to the qualified molten iron requirement of table 1;

[0034] 1.4....

Embodiment 2

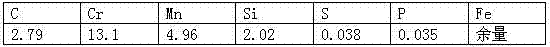

[0038] The chemical composition of manganese silicon high chromium cast iron is as shown in table 2 in weight percentage:

[0039] Table 2 Manganese silicon high chromium cast iron composition and content (wt%)

[0040]

[0041] 1.1. Raw material selection

[0042] In percent by weight, steel scrap, pig iron, ferrochrome, ferromanganese and ferrosilicon are batched according to the composition requirements of Table 2;

[0043] 1.2. Bake ferrochromium, ferromanganese and ferrosilicon to remove moisture and surface oil stains of ferrochromium, ferromanganese and ferrosilicon; put scrap steel and pig iron into induction furnace for melting, then perform pre-deoxidation operation , and then add baked ferrochromium, ferromanganese and ferrosilicon to obtain molten iron;

[0044] 1.3, take molten iron sample and carry out pre-stove analysis, according to analysis result, adjust described molten iron composition to the qualified molten iron requirement of table 2;

[0045] 1.4....

Embodiment 3

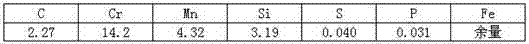

[0049] The chemical composition of manganese silicon high chromium cast iron is shown in Table 3 in weight percentage:

[0050] Table 3 Manganese silicon high chromium cast iron composition and content (wt%)

[0051] C Cr mn Si S P Fe 2.66 13.9 4.83 3.16 0.039 0.036 margin

[0052] 1.1. Raw material selection

[0053] In percent by weight, steel scrap, pig iron, ferrochrome, ferromanganese and ferrosilicon are batched according to the composition requirements of table 3;

[0054] 1.2. Bake ferrochromium, ferromanganese and ferrosilicon to remove moisture and surface oil stains of ferrochromium, ferromanganese and ferrosilicon; put scrap steel and pig iron into induction furnace for melting, then perform pre-deoxidation operation , and then add baked ferrochromium, ferromanganese and ferrosilicon to obtain molten iron;

[0055] 1.3, take molten iron sample and carry out pre-stove analysis, according to analysis result, adjust described molten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com