Anti-ultraviolet and antibacterial fiber

An anti-ultraviolet and anti-ultraviolet agent technology, applied in the field of anti-ultraviolet and antibacterial fibers, can solve the problems of poor physical properties of fiber products, poor antibacterial effect and anti-ultraviolet effect, and high cost of antibacterial materials, and achieves simple production process, antibacterial effect. Long time and low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

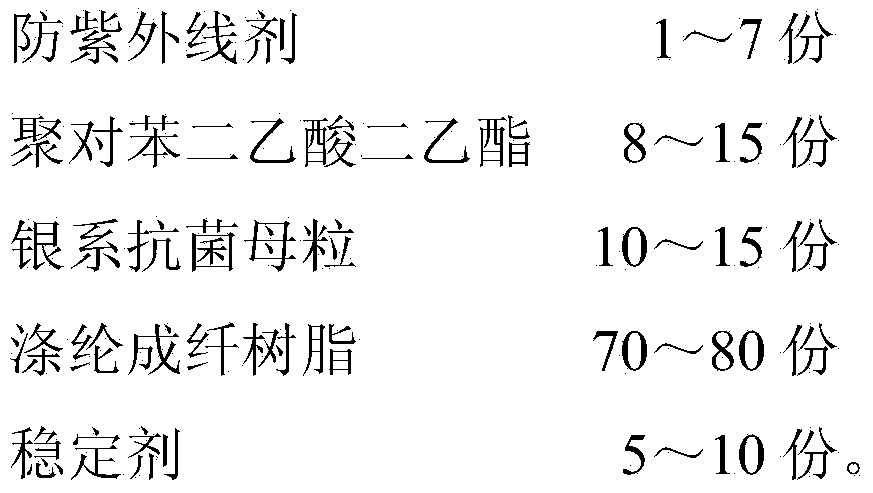

[0021] An anti-ultraviolet and antibacterial fiber, said anti-ultraviolet and antibacterial fiber is composed of anti-ultraviolet agent, polyethylene terephthalate, silver-based antibacterial masterbatch and polyester fiber-forming resin, each component The parts by weight are as follows:

[0022]

[0023] The above-mentioned composite inorganic and organic anti-ultraviolet agents are TiO containing 10% by weight 2 , 10% UV absorber and 80% polyethylene terephthalate blended.

[0024] The silver-based antibacterial masterbatch is prepared by blending 20% by weight of nano-silver ions and nano-carrier silicon dioxide with 80% by weight of polyethylene terephthalate.

[0025] During preparation, the components can be blended according to conventional methods in this field. The anti-ultraviolet and antibacterial fibers obtained in this example are tested according to conventional methods in this field. The antibacterial effects of Bacillus and Candida albicans reached 98%,...

Embodiment 2

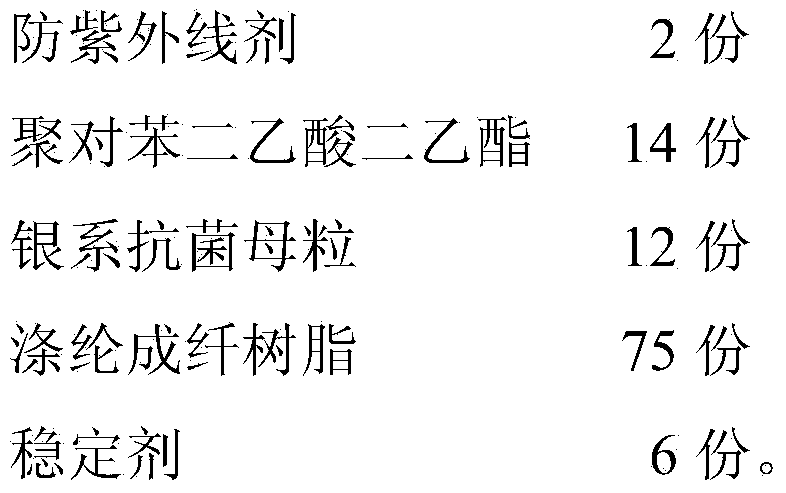

[0027] An anti-ultraviolet and antibacterial fiber, said anti-ultraviolet and antibacterial fiber is composed of anti-ultraviolet agent, polyethylene terephthalate, silver-based antibacterial masterbatch and polyester fiber-forming resin, each component The parts by weight are as follows:

[0028]

[0029] The above-mentioned composite inorganic and organic anti-ultraviolet agents are TiO containing 10% by weight 2 , 10% UV absorber and 80% polyethylene terephthalate blended.

[0030] The silver-based antibacterial masterbatch is prepared by blending 20% by weight of nano-silver ions and nano-carrier silicon dioxide with 80% by weight of polyethylene terephthalate.

[0031] During preparation, the components can be blended according to conventional methods in this field. The anti-ultraviolet and antibacterial fibers obtained in this example are tested according to conventional methods in this field. The antibacterial effects of Bacillus and Candida albicans reached 93%,...

Embodiment 3

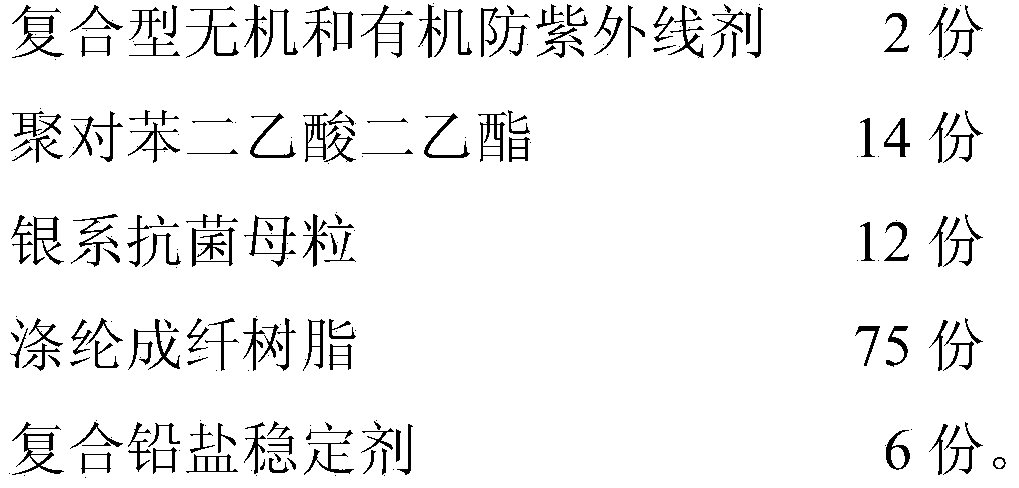

[0033] An anti-ultraviolet and antibacterial fiber, said anti-ultraviolet and antibacterial fiber is composed of anti-ultraviolet agent, polyethylene terephthalate, silver-based antibacterial masterbatch and polyester fiber-forming resin, each component The parts by weight are as follows:

[0034]

[0035] The above-mentioned composite inorganic and organic anti-ultraviolet agents are TiO containing 10% by weight 2 , 10% UV absorber and 80% polyethylene terephthalate blended.

[0036] The silver-based antibacterial masterbatch is prepared by blending 20% by weight of nano-silver ions and nano-carrier silicon dioxide with 80% by weight of polyethylene terephthalate.

[0037] During preparation, the components can be blended according to conventional methods in this field. The anti-ultraviolet and antibacterial fibers obtained in this example are tested according to conventional methods in this field. The antibacterial effects of Bacillus and Candida albicans reached 96%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com