Early fault detection system of low-speed heavy-load machine

A technology of early failure, low speed and heavy load, applied in the testing of machine/structural components, measuring devices, instruments, etc., can solve the problem that it is difficult to effectively collect vibration and shock signals of equipment to be diagnosed, the sensitivity of acceleration sensors is limited, and the time of fault shock signals Long interval and other problems, to achieve the effect of convenient extraction, fewer sampling points, and accurate fault judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] An early fault detection system for low-speed and heavy-duty machinery. The low-speed and heavy-duty machinery is a continuous casting ladle turret, and its rolling bearing parameters are: bearing pitch diameter of 39.5mm, rolling element diameter of 7.5mm, 12 rolling elements, and rotation speed of 45rpm.

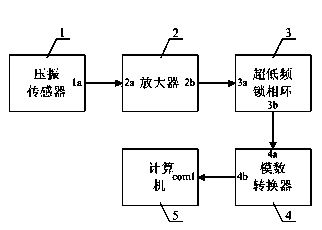

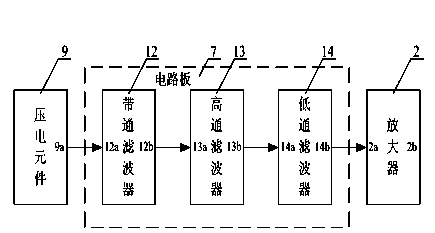

[0034] The early fault detection system described in this embodiment is figure 1 As shown, it includes a pressure vibration sensor 1, an amplifier 2, an ultra-low frequency phase-locked loop 3, an analog-to-digital converter 4 and a computer 5. The signal output terminal 1a of the vibration pressure sensor 1 is connected to the signal input terminal 2a of the amplifier 2, the signal output terminal 2b of the amplifier 2 is connected to the signal input terminal 3a of the ultra-low frequency phase-locked loop 3, and the signal output terminal of the ultra-low frequency phase-locked loop 3 3b is connected to the analog input terminal 4a of the analog to digital converter...

Embodiment 2

[0049] An early fault detection system for low-speed and heavy-duty machinery. Except for the following technical parameters, the rest are the same as in Example 1.

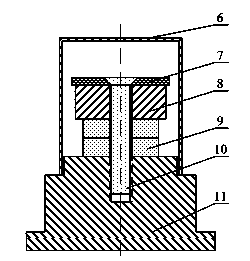

[0050] In this embodiment: the material of the mass 8 is iron; the material of the piezoelectric element 9 is lead zirconate titanate ceramic.

[0051] The vibration signal of the continuous casting ladle turret bearing vibration signal collected by the pressure vibration sensor 1 in the early fault detection system of this embodiment is as follows: Figure 7 As shown, although there is noise interference in the vibration signal, it is not difficult to find the impact signal component with a larger amplitude.

[0052] The impact signal extracted by the early fault detection software for low-speed and heavy-duty machinery in this embodiment is as follows Figure 8 Shown, with Figure 7 In comparison, the detection software accurately extracts the impact component in the bearing vibration signal, effectively filtering out...

Embodiment 3

[0054] An early fault detection system for low-speed and heavy-duty machinery. Except for the following technical parameters, the rest are the same as in Example 1.

[0055] In this embodiment: the mass 8 is made of aluminum; the piezoelectric element 9 is made of lead magnesium niobate ceramic.

[0056] The bearing vibration signal collected by the pressure vibration sensor 1 in the early fault detection system described in this embodiment is as follows: Picture 9 As shown, although there is noise interference in the vibration signal, it is not difficult to find the impact signal component with a larger amplitude.

[0057] The impact signal extracted by the early fault detection software for low-speed and heavy-duty machinery in this embodiment is as follows Picture 10 Shown, with Picture 9 In comparison, the detection software accurately extracts the impact component in the bearing vibration signal, effectively filtering out most of the background noise, Picture 10 The calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com