Lithium ion battery diaphragm with polymer inorganic coating and preparation method for lithium ion battery diaphragm

A lithium-ion battery, inorganic coating technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of large friction loss, unfavorable large-scale continuous production, and difficult to control the uniformity and uniformity of coating thickness. To achieve the effect of large bonding force, easy control of uniformity and consistency, and small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing a polymer inorganic lithium-ion battery diaphragm, comprising the following preparation steps:

[0026] 1. Add water-soluble polymer thickener, water-based dispersant and water into the mixing tank and stir evenly to obtain mixture I;

[0027] 2. Add polymer particles and ceramic particles to mixture I and stir, and disperse in a disperser. After stirring for 25-50 minutes, disperse in a high-speed disperser at a speed of 3000-9000rpm to obtain mixture II;

[0028] 3. Add water-based latex to the mixture II, stir evenly, and filter with a 300-mesh stainless steel screen to obtain a polymer inorganic slurry;

[0029] 4. Coat the polymer inorganic slurry on one or both sides of the polyolefin porous membrane, and obtain a polymer inorganic coating lithium-ion battery separator after drying; coating can be done by dip coating, roll coating, spray coating or Die coating method.

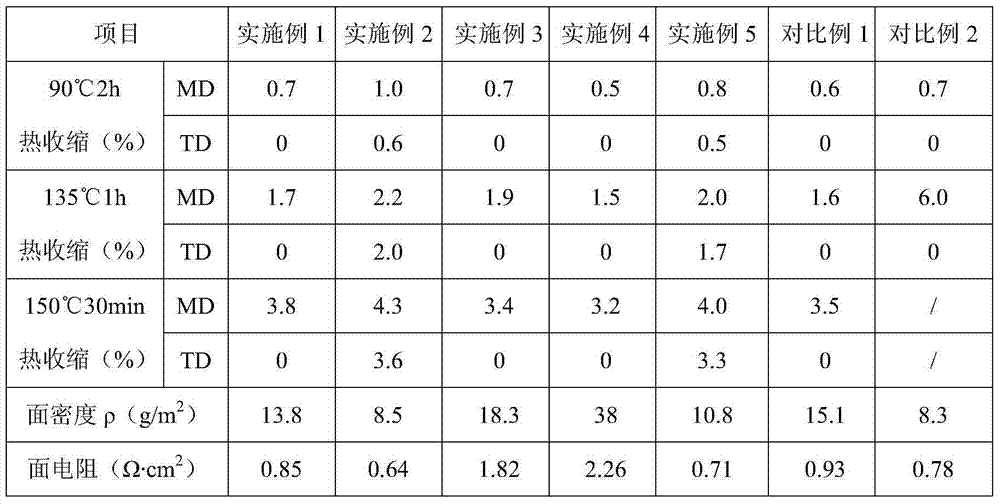

Embodiment 1

[0033] A polymer inorganic lithium-ion battery diaphragm, first, 0.1% of the water-soluble polymer thickener hydroxyethyl cellulose and 0.1% of the water-based dispersant ethylene glycol are added to 80% of the water, at room temperature, Stir at a speed of 400 rpm for 20 minutes until completely dissolved; then add 90% polymer particle polyimide, D50 is 4um, BET is 2m2 / g, 10% silicon dioxide particles, D50 is 0.2um, BET is 15m2 / g, added to the above solution, stirred at 800 rpm for 10 minutes, then dispersed in a disperser at 3000 rpm until completely dissolved; then, 0.% water-based latex styrene-acrylic latex was added to the above solution , stirred evenly; then filtered with a 300-mesh stainless steel screen to obtain a polymer inorganic slurry; finally coated on both sides of the polypropylene porous membrane by dip coating, and dried to obtain a polymer inorganic coated lithium-ion battery separator.

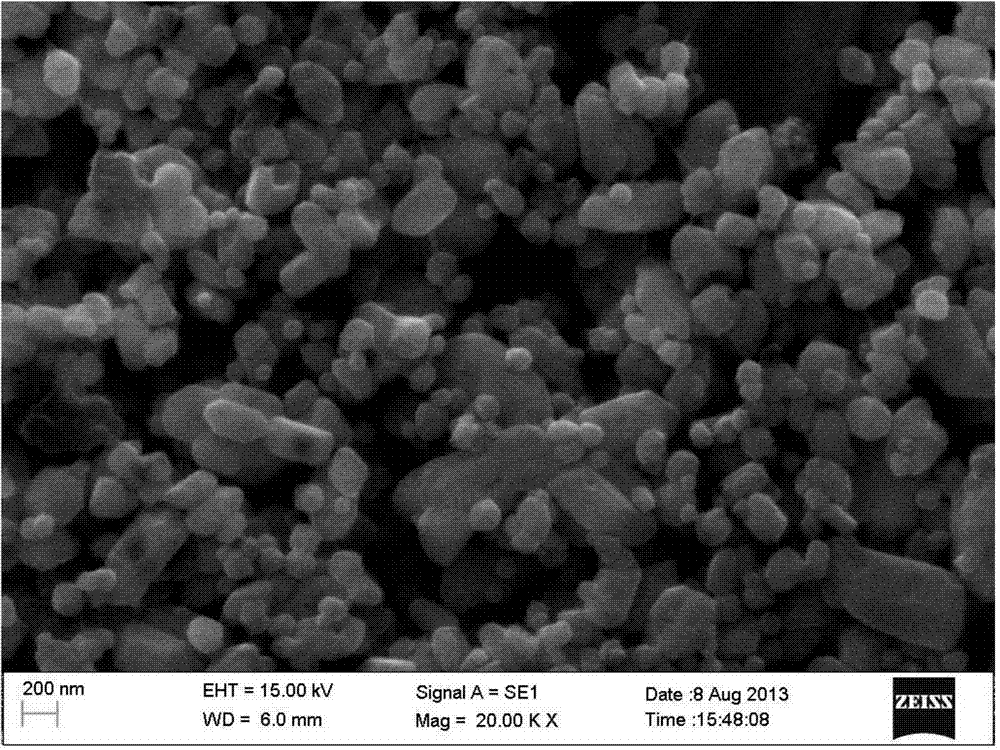

[0034] refer to figure 1 , figure 1 It is an electron microscope p...

Embodiment 2

[0036] A polymer inorganic lithium-ion battery diaphragm, first, 5% of the water-soluble polymer thickener sodium carboxymethyl cellulose and 5% of the water-based dispersant polyacrylic acid are added to 70% of the water, at room temperature, Stir at a speed of 400 rpm for 15 minutes until completely dissolved; then add 30% polyphenylene sulfide polymer particles, D50 is 4um, BET is 2m2 / g, 50% aluminum oxide particles, D50 is 0.2um, BET 15m2 / g, add to the above solution, stir at 800 rpm for 10 minutes, then disperse in a disperser at 9000 rpm until completely dissolved; then, add 10% water-based latex styrene-butadiene latex to the above solution , stirred evenly; then filtered with a 300-mesh stainless steel screen to obtain a polymer inorganic slurry; finally coated on both sides of the polypropylene porous membrane by dip coating, and dried to obtain a polymer inorganic coated lithium-ion battery separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com