Method for recycling zinc oxide waste desulfurizers and co-producing ammonium sulfate

A technology of zinc oxide and ammonium sulfate, applied in the field of desulfurizers, can solve the problems of high zinc loss rate, high treatment cost, serious environmental pollution, etc., and achieve the effect of improving the recycling rate and avoiding the loss of zinc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

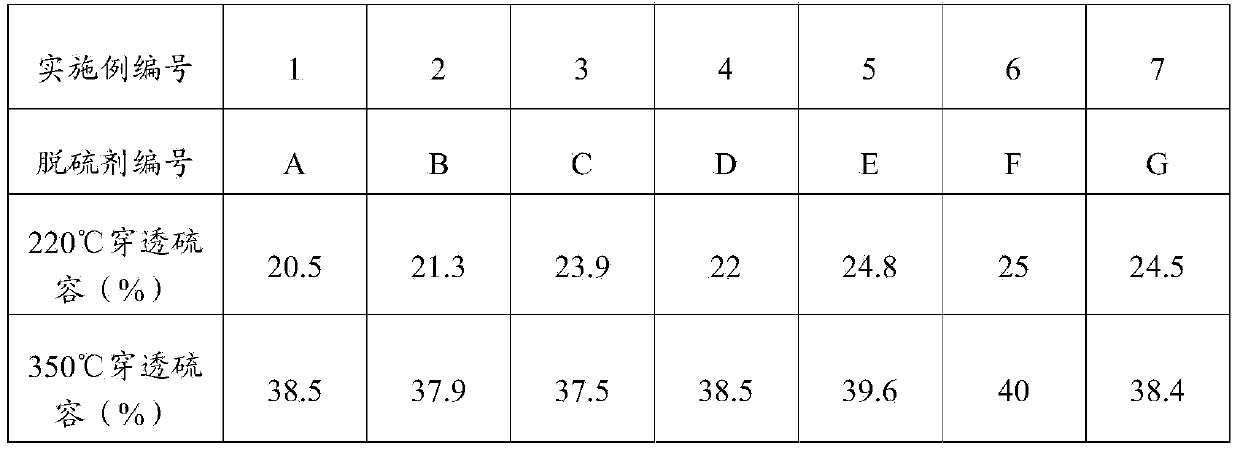

Examples

Embodiment 1

[0029] (1) Roast 100g of zinc oxide desulfurization waste agent at 850°C to obtain inactive zinc oxide material;

[0030] (2) Dissolving the inactive zinc oxide material in the step (1) in water to prepare an inactive zinc oxide slurry with a concentration of 20 wt%, adding sulfuric acid with a volume concentration of 40% to the inactive zinc oxide slurry , wherein the molar ratio of zinc ions to the sulfuric acid in the inactive zinc oxide slurry is 1:1, after the reaction is completed, filter to obtain filter residue and zinc sulfate filtrate;

[0031](3) Add solid ammonium bicarbonate to the zinc sulfate filtrate in the step (2), wherein the molar ratio of zinc ions in the zinc sulfate filtrate to the ammonium bicarbonate is 1:2, at 30°C Reaction, during the reaction, the pH value of the solution is controlled to be 6.8 until the reaction is completed;

[0032] (4) Keep the pH value of the solution after the reaction in step (3) at 6.8, raise the temperature of the solutio...

Embodiment 2

[0036] (1) Roast 100g of zinc oxide desulfurization waste agent at 860°C to obtain inactive zinc oxide material;

[0037] (2) Dissolving the inactive zinc oxide material in the step (1) in water to prepare an inactive zinc oxide slurry with a concentration of 22wt%, adding sulfuric acid with a volume concentration of 45% to the inactive zinc oxide slurry , wherein the molar ratio of zinc ions to the sulfuric acid in the inactive zinc oxide slurry is 1.02:1, after the reaction is completed, filter to obtain filter residue and zinc sulfate filtrate;

[0038] (3) Add solid ammonium bicarbonate to the zinc sulfate filtrate in the step (2), wherein the molar ratio of zinc ions in the zinc sulfate filtrate to the ammonium bicarbonate is 1:2.1, at 32°C Reaction, during the reaction, the pH value of the solution is controlled to be 6.8 until the reaction is completed;

[0039] (4) Keep the pH value of the solution after the reaction in step (3) at 6.8, raise the temperature of the so...

Embodiment 3

[0043] (1) Roast 100g of zinc oxide desulfurization waste agent at 870°C to obtain inactive zinc oxide material;

[0044] (2) Dissolving the inactive zinc oxide material in the step (1) in water to prepare an inactive zinc oxide slurry with a concentration of 25 wt%, adding sulfuric acid with a volume concentration of 48% to the inactive zinc oxide slurry , wherein the molar ratio of zinc ions to the sulfuric acid in the inactive zinc oxide slurry is 1:1, after the reaction is completed, filter to obtain filter residue and zinc sulfate filtrate;

[0045] (3) Add solid ammonium bicarbonate to the zinc sulfate filtrate in the step (2), wherein the molar ratio of zinc ions in the zinc sulfate filtrate to the ammonium bicarbonate is 1:2.2, at 32°C Reaction, during the reaction, the pH value of the solution is controlled to be 6.9 until the end of the reaction;

[0046] (4) Keep the pH value of the solution after the reaction in step (3) at 6.9, raise the temperature of the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com