Solar sea water evaporator

A solar distiller and seawater evaporation technology, which is applied in energy wastewater treatment, general water supply conservation, water/sewage treatment, etc., can solve problems such as limited operating temperature, low output, and large heat capacity of seawater, so as to improve light absorption efficiency and reduce operating costs. Cost, the effect of increasing water production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

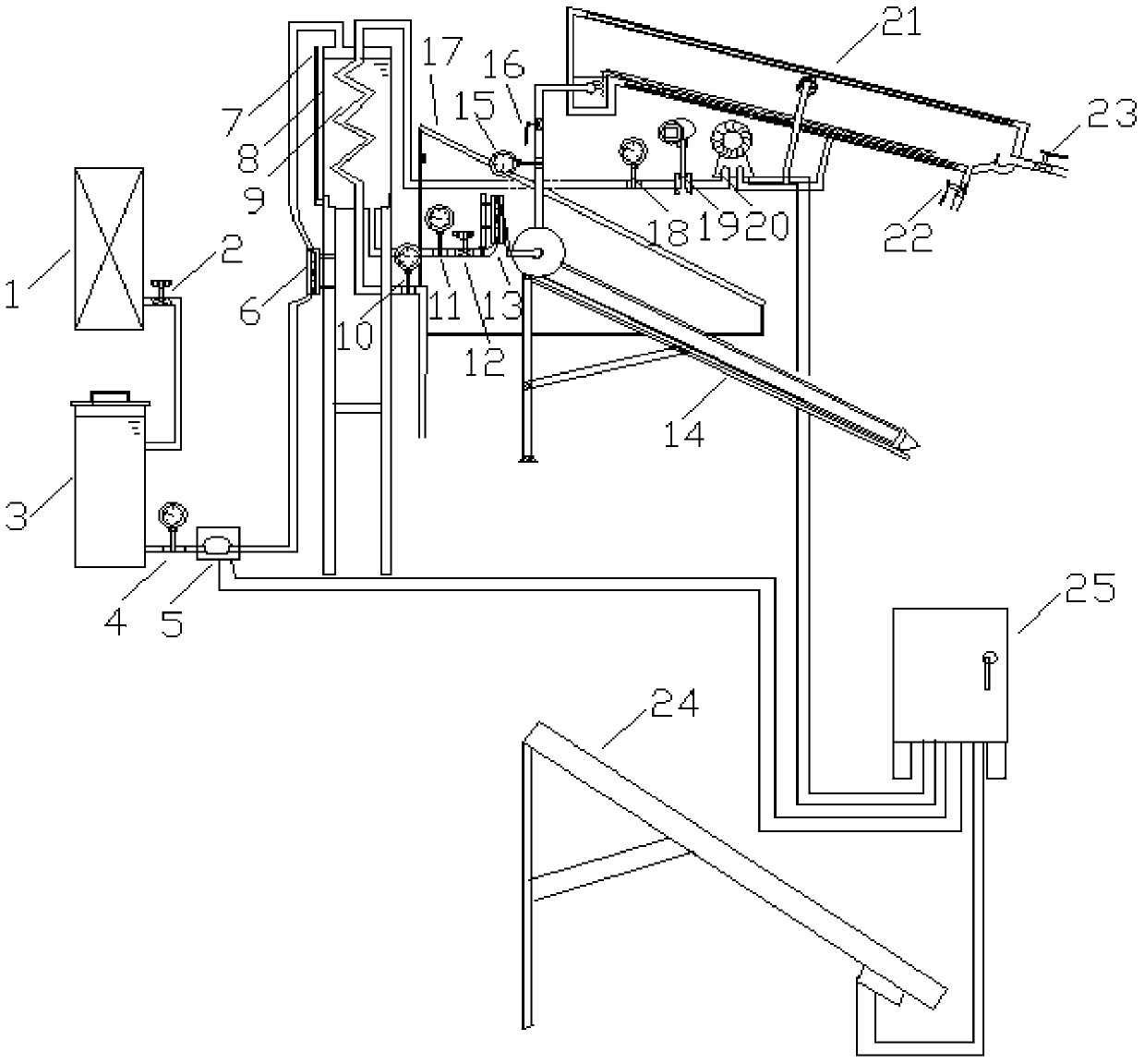

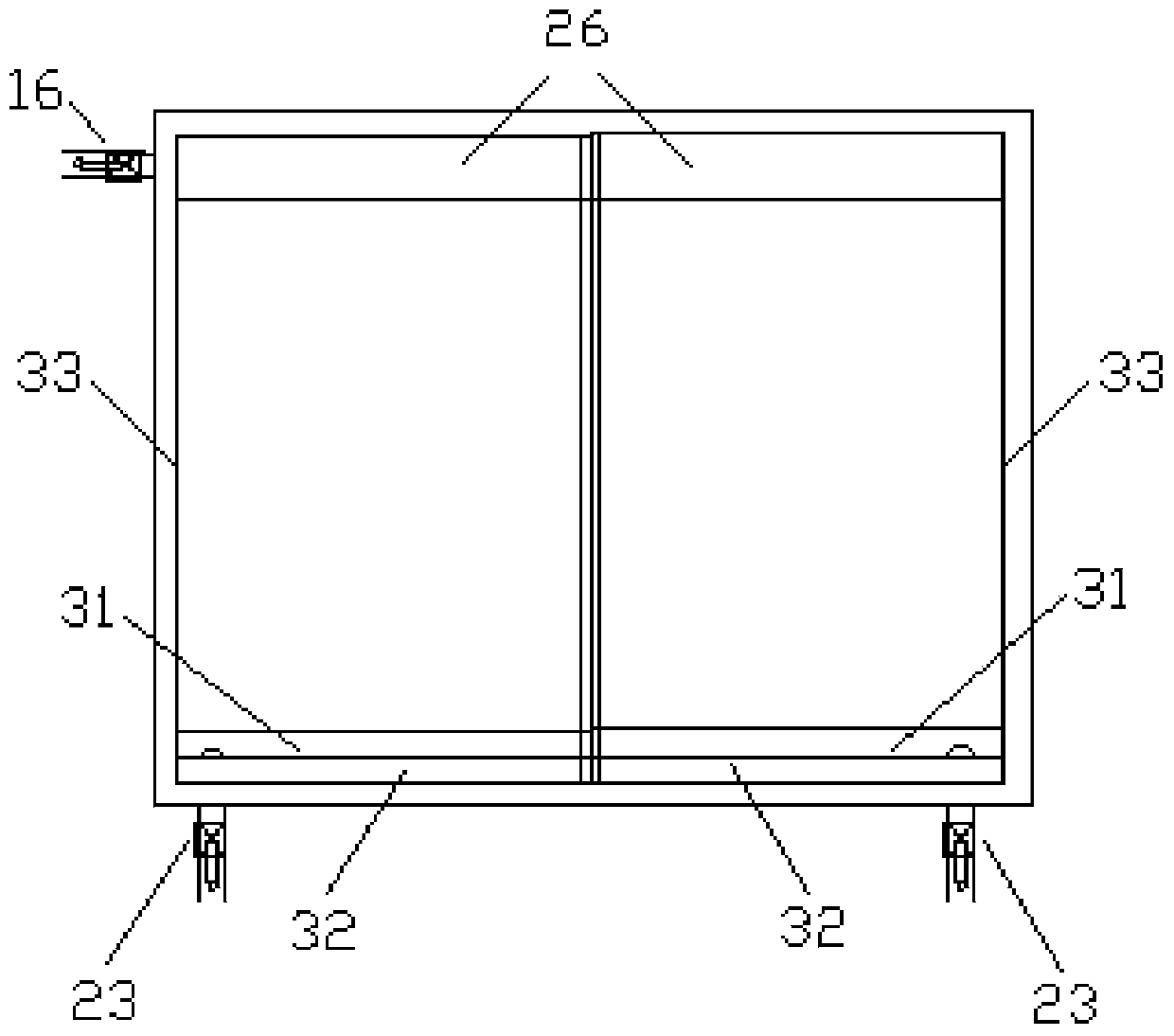

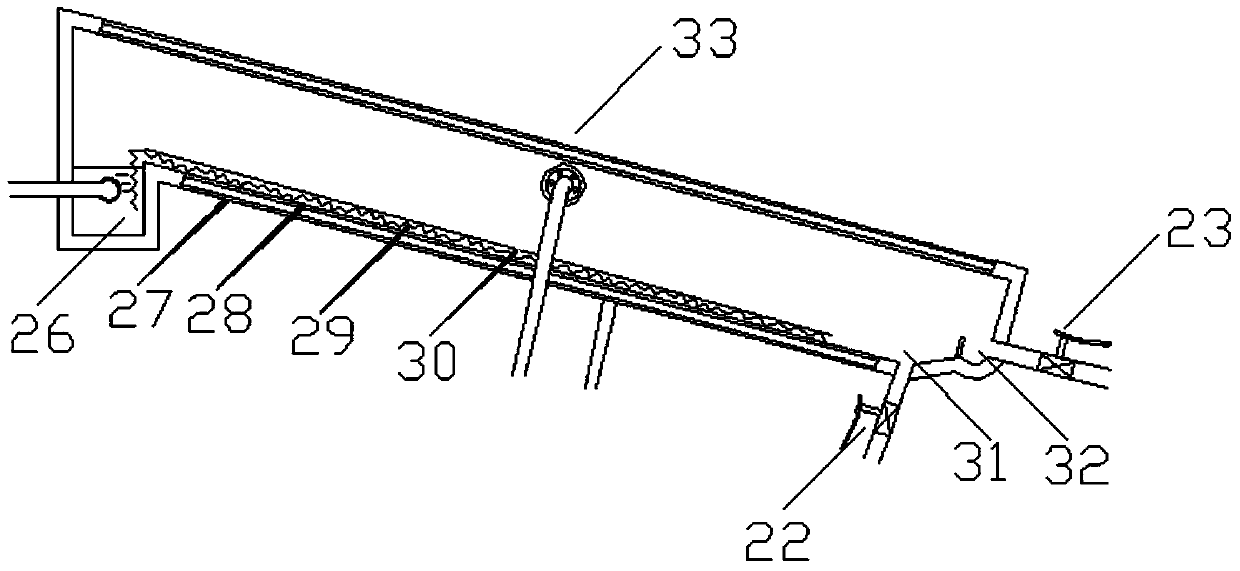

[0019] A solar seawater evaporator provided by the invention includes a seawater pretreatment unit, a seawater tank, a lift pump, a water exchange tank, a spiral heat exchange tube, a condensed water collection place, a solar heat pipe heat collector, a solar distiller, an air pump, Fresh water collection, concentrated brine collection, reflectors, solar panels, distribution boxes, liquid level gauges, thermometers, flow meters, steam flow meters. The seawater pipeline is connected to the seawater pretreatment unit, valve, seawater tank, thermometer, lift pump, flowmeter, upper and lower ends of the heat exchange tank, thermometer, valve, flowmeter, solar heat pipe collector, thermometer, valve, and solar still sea tank. The steam pipes are sequentially connected to the two sides of the solar still, close to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com