Chlorite suspension rich in micro-aerobic bubbles and method for removing odor-causing pollutants in anaerobic water body by utilizing chlorite loaded with micro-aerobic bubbles

A technology for chlorite and pollutants, applied in the direction of oxidized water/sewage treatment, etc., can solve problems such as not being effectively solved, achieve good governance effect, increase dissolved oxygen content, and improve the effect of dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to the present invention, at first prepare the chlorite suspension that is rich in micro-oxygen bubbles, the method is as follows:

[0026] 1. Modification and pretreatment of collected chlorite:

[0027] (1) Smash. Grind the collected natural chlorite in a pulverizer, and select a sample with a particle size of 10-100 μm after sieving.

[0028] (2) Remove organic matter. Add 10% H to the crushed chlorite sample 2 o 2 Repeat the process until no obvious bubbles overflow.

[0029] (3) Calcification and drying. Add 10~25% CaCl to the chlorite after removing organic matter according to the solid-to-liquid ratio of 1:1 2 Aqueous solution, soak for more than 24 hours, shake the chlorite suspension from time to time to ensure uniform mixing, and then use deionized water to repeatedly shake and wash on the shaker for 3 to 5 times until there is no Ca in the supernatant after centrifugation. 2+ until. After centrifugation, the supernatant was discarded, and th...

Embodiment 2

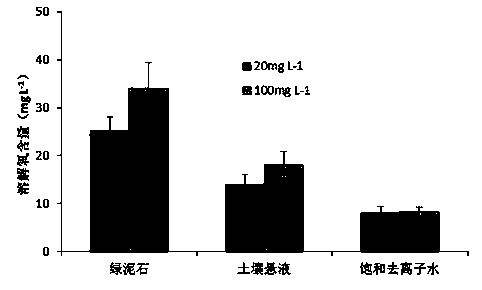

[0033] Select 5 ml of the prepared chlorite suspension concentrate loaded with micro-oxygen bubbles, add it to 100 ml of deionized water for dilution. 20 mg L was finally prepared -1 and 100 mg L -1Two systems of chlorite suspension. Then adopt the iodometric method to measure the content of dissolved oxygen therein, and shake and mix from time to time during the measurement process. Two sets of control experiments were done at the same time, that is, adding 5ml of air-saturated deionized water and adding 5ml of saturated soil suspension to 100ml of deionized water. The soil is general farmland soil, and the specific treatment is basically the same as the pretreatment of chlorite, including crushing and sieving, removing organic matter, calcification and drying, high-temperature roasting, and finally obtaining a suspension. During the experiment, the value of dissolved oxygen in the water body was recorded. Specific results such as figure 1 As shown, this figure specific...

Embodiment 3

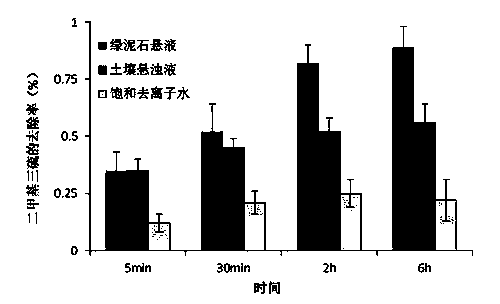

[0035] According to relevant literature reports, the drinking water crisis broke out in Wuxi in 2007, and the odor-causing substances in the lake water were mainly sulfide pollutants, among which dimethyl trisulfide was the main characteristic pollutant. In the indoor simulation experiment, the initial concentration in 200 ml was 30 mg L -1 In the simulated wastewater of dimethyl trisulfide, 5ml of high-concentration chlorite suspension with high-efficiency loading micro-air bubbles was added, so that the content of chlorite particles in the final water body was 20~100mg L -1 , start stirring. Two sets of control experiments were done at the same time, that is, adding 5ml of air-saturated deionized water and adding 5ml of saturated soil suspension to 100ml of deionized water. The soil is general farmland soil, and the specific treatment is basically the same as the pretreatment of chlorite, including crushing and sieving, removing organic matter, calcification and drying, hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com