Underground building superstrong deep penetration crystallization type waterproof material

A technology of underground construction and osmotic crystallization, which is applied in the field of waterproof materials for underground construction, and can solve problems such as high waterproof cost, poor waterproof effect, and difficult filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and specific embodiments:

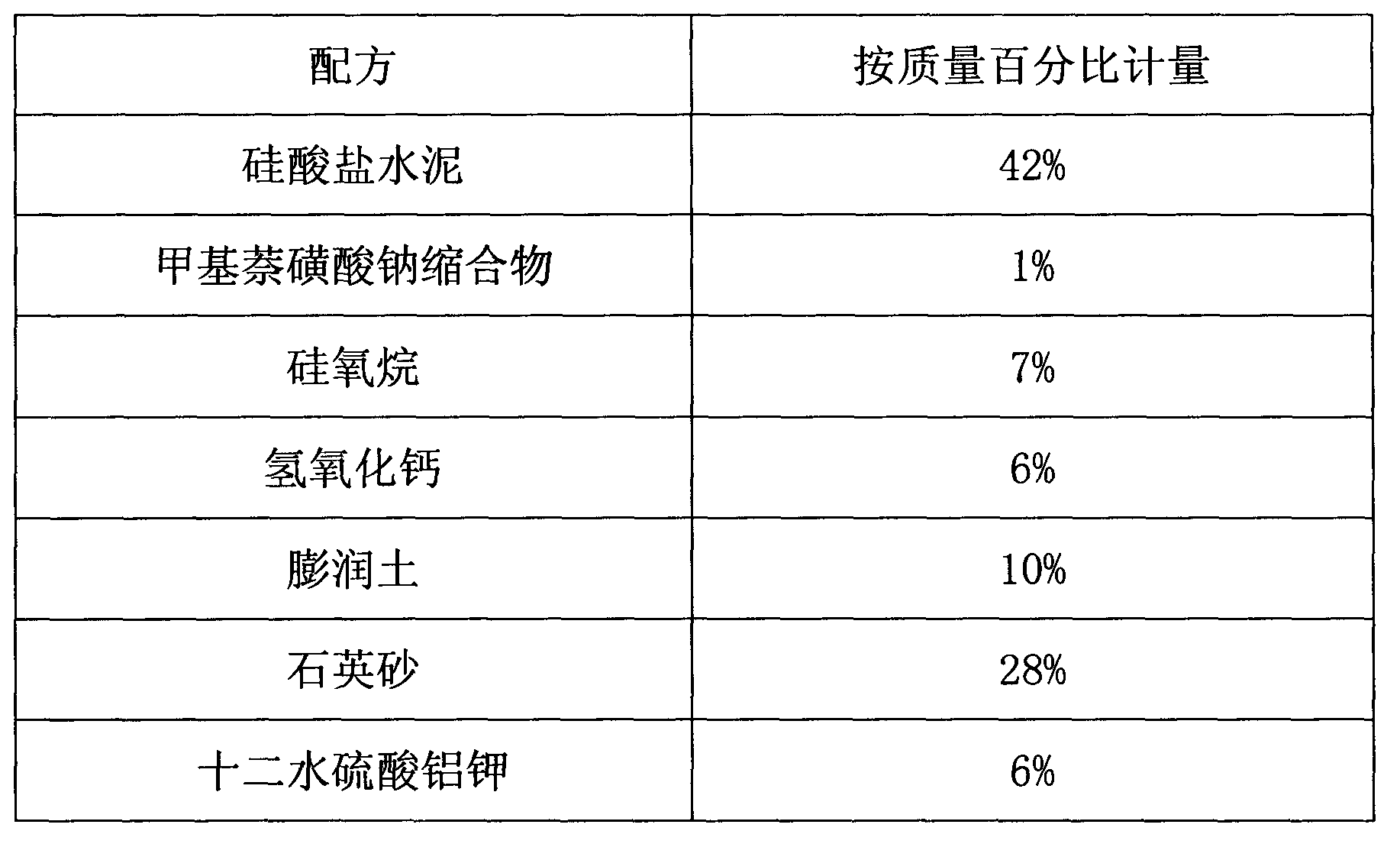

[0028] The super deep penetration crystalline waterproof material for underground construction includes the following components in important percentages: Portland cement 42%,

[0029] Condensate of sodium methyl naphthalene sulfonate 1%,

[0030] 7% siloxane,

[0032] Bentonite 10%,

[0033] Quartz sand 28%,

[0034] It is composed of 6% potassium aluminum sulfate dodecahydrate. The preparation method is as follows: add siloxane emulsion to bentonite and stir evenly, and then dry the slurry; grind into powder in a ball mill, generally 150-250 mesh, and then Add the surface active dispersant sodium methyl naphthalene sulfonate and quartz sand, stir to form agglomerates, finally add Portland cement, sodium silicate, potassium aluminum sulfate dodecahydrate, calcium hydroxide, and finally make the finished product.

[0035] The said Portlan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com