Light hydrocarbon separation method used in methanol to olefin device

A technology of methanol to olefins and separation method, applied in the field of light hydrocarbon separation, can solve the problems of large equipment investment and high operating costs, and achieve the effects of low operating costs, improving recovery rate, and saving equipment investment and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

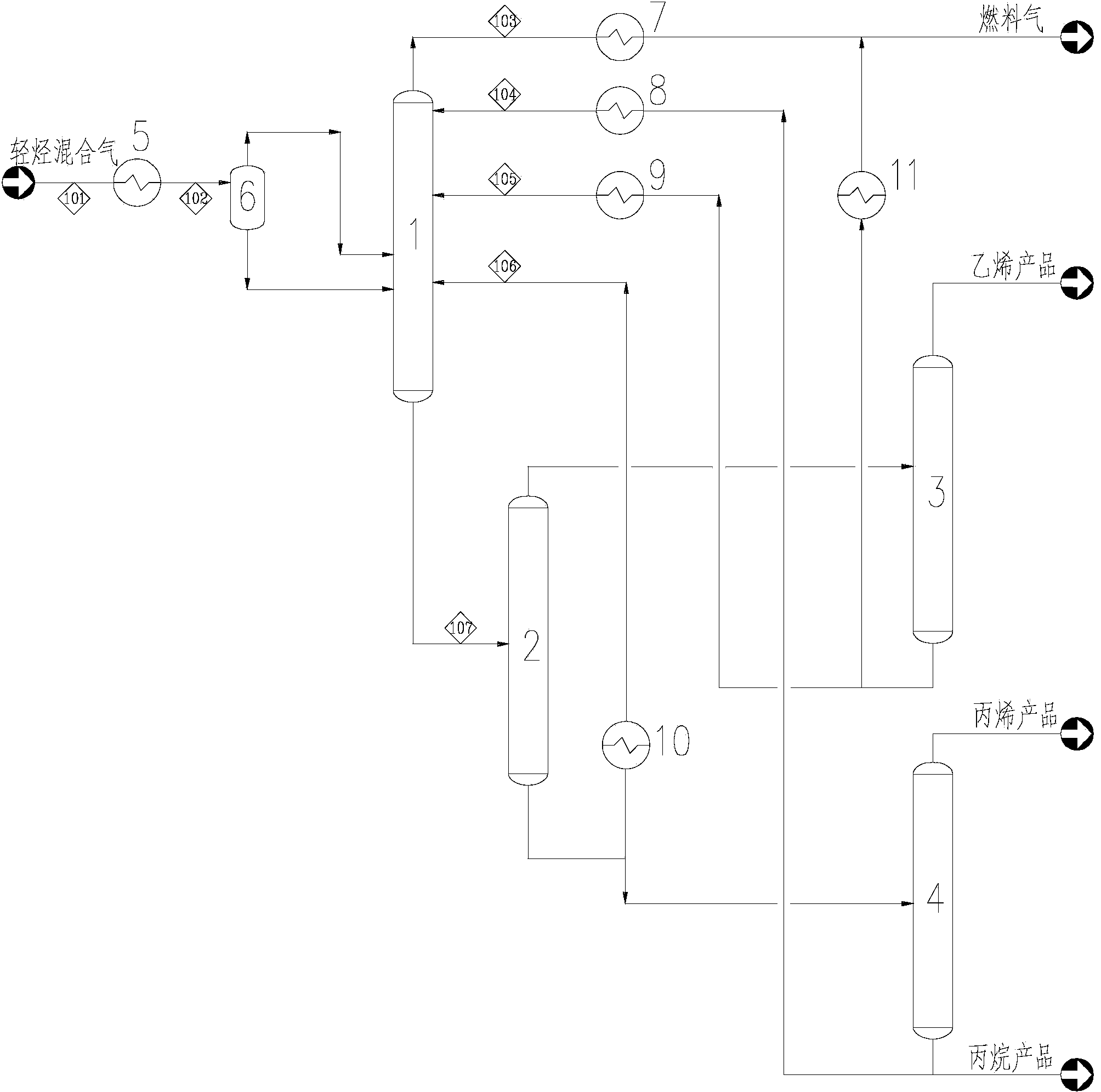

Method used

Image

Examples

specific Embodiment 1

[0073] The operating pressure at the top and bottom of the demethanizer and the operating temperature at the top and bottom of the tower are shown in the table below:

[0074] project

Embodiment 1

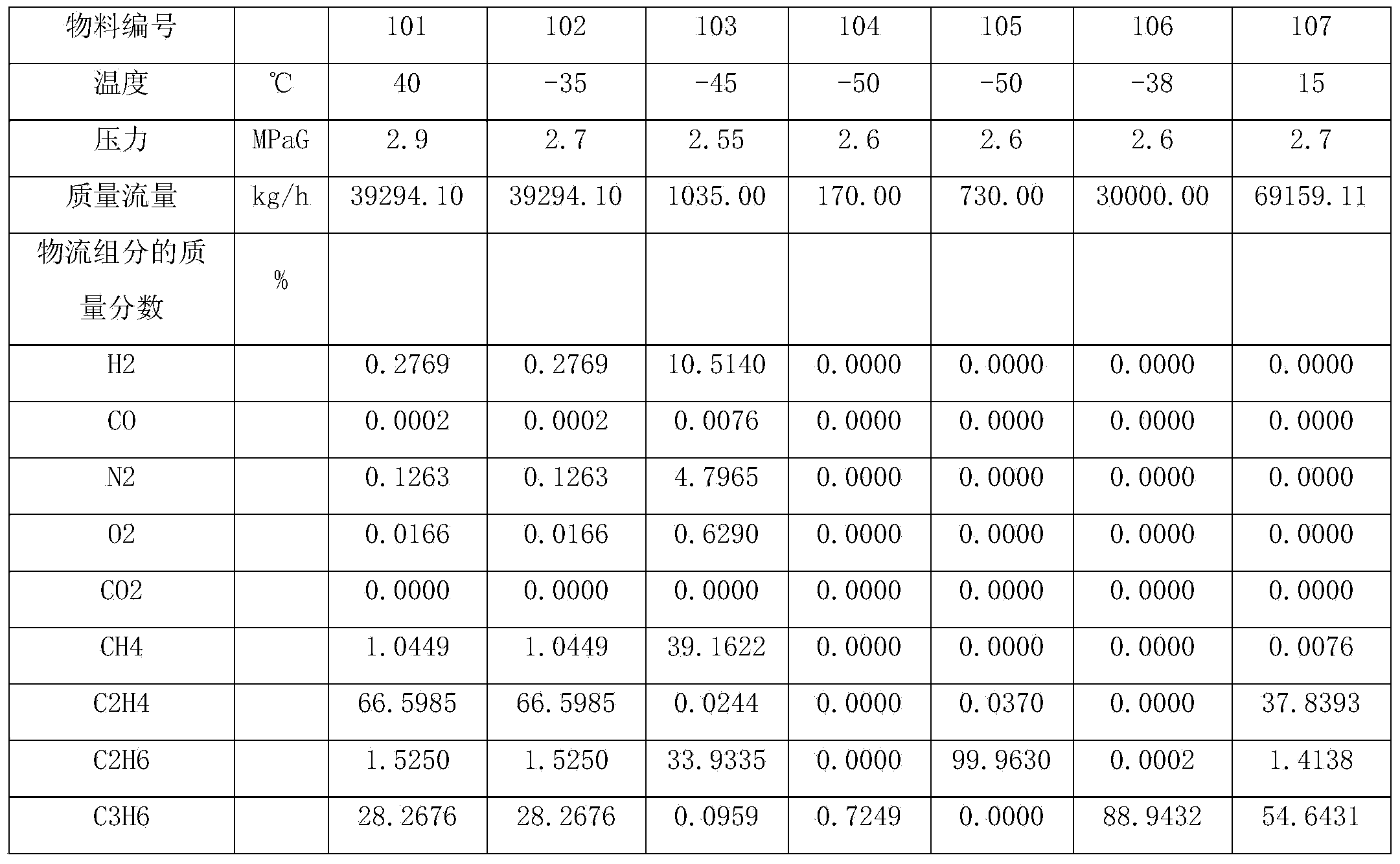

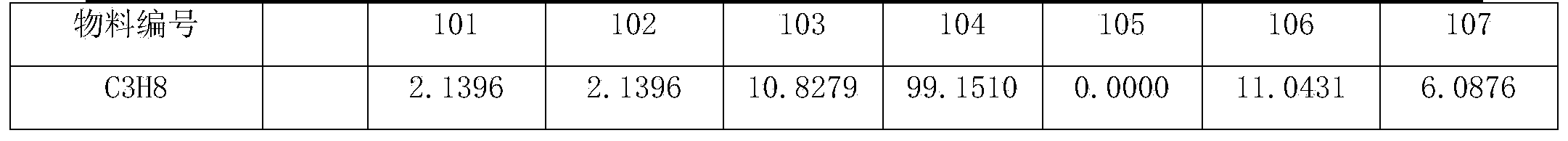

[0075] The flow process simulation calculation result of embodiment 1 sees the following table:

[0076]

[0077]

[0078] From the above results, it can be seen that if the operating parameters of the demethanizer are set according to the data in the table, the temperature of the demethanizer tower is 15°C, which can match a variety of low-grade heat sources and realize the comprehensive utilization of energy. At the same time, control the C3 mixture absorption liquid, propane absorption liquid and ethane absorption liquid according to the flow rate in the above table, that is, the flow rate of propane absorption liquid is 170kg / h, the temperature is -50℃, and the flow rate of ethane absorption liquid is 730kg / h , the temperature is -50°C, the flow rate of the absorbed carbon three liquid is 30000kg / h, and the temperature is -38°C, the ethylene concentration in the gas phase at the top of the demethanizer can be controlled below 300ppm, and the propylene concentration ca...

Embodiment 2

[0079] In embodiment 2, the operating pressure at the top and bottom of the demethanizer and the operating temperature at the top and bottom of the tower are shown in the table below:

[0080] project

unit

Demethanizer top / bottom temperature

℃

-43 / 22

Demethanizer top / bottom pressure

MPaG

2.9 / 3.05

[0081] The flow process simulation calculation result of embodiment 2 sees the following table:

[0082]

[0083]

[0084] From the above results, it can be seen that if the operating parameters of the demethanizer are set according to the data in the table, the temperature of the demethanizer tower is 22°C, which can match a variety of low-grade heat sources and realize the comprehensive utilization of energy. At the same time, control the C3 mixture absorption liquid, propane absorption liquid and ethane absorption liquid according to the flow rate in the above table, that is, the flow rate of propane absorption liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com