A kind of reactive polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot melt adhesive, reactive technology, applied in the chemical field, can solve the problems of slow curing speed, poor thermal shock resistance, poor aging resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

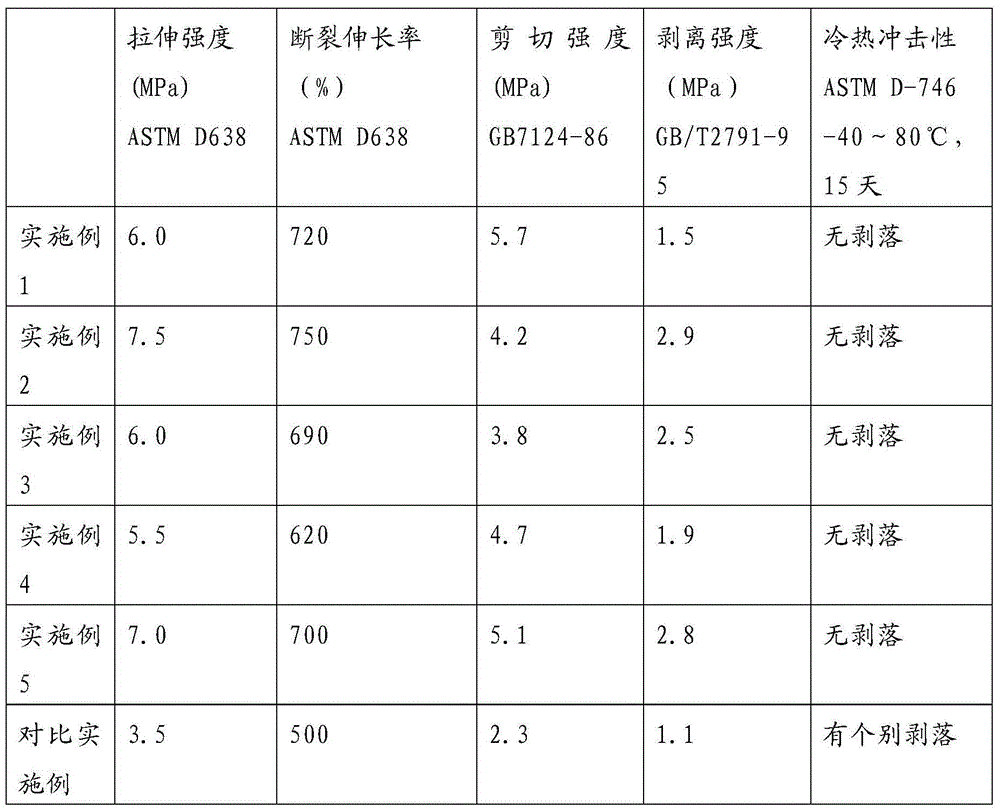

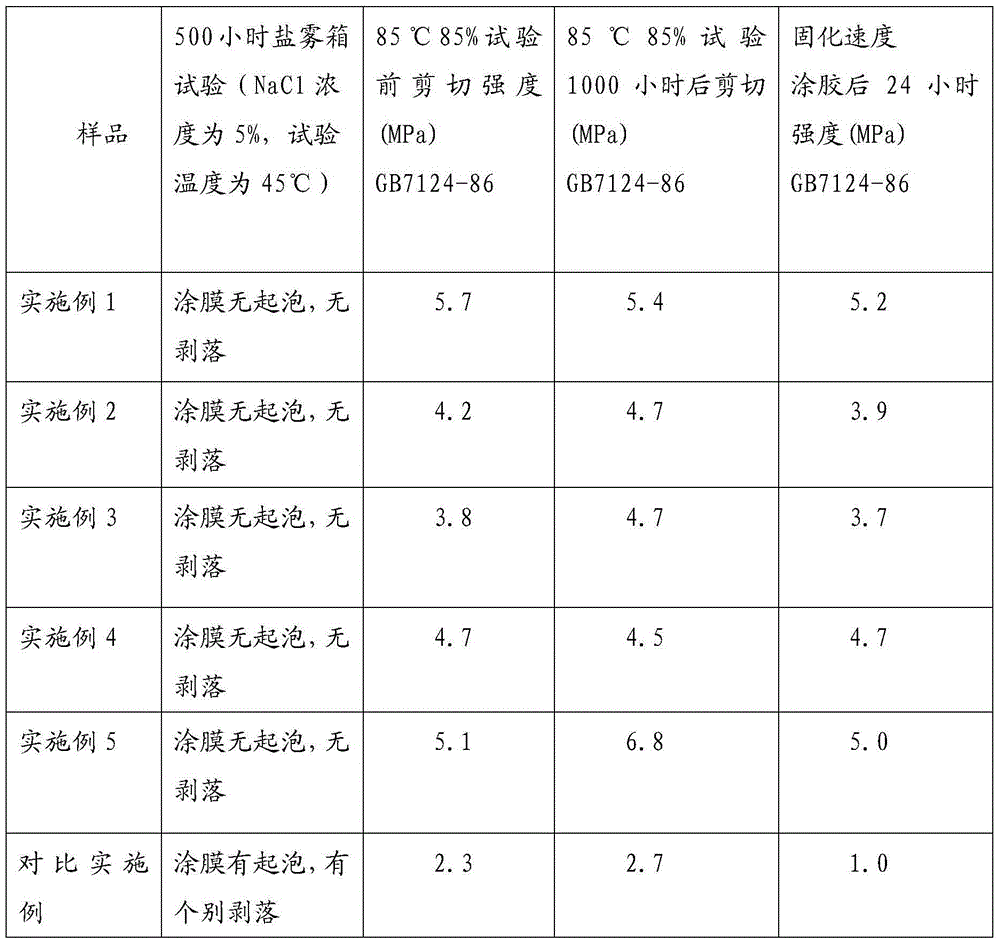

Examples

Embodiment 1

[0028] Add 21 parts of polyether polyol PPG2100 and 43 parts of polyester polyol POL-356T into the reaction kettle, vacuum dehydrate at 120°C for 2 hours, and keep the vacuum at -0.09MPa. Then cool to 80°C, add 10 parts of reactive plasticizer "Nikanol" resin and 14 parts of 4,4'diphenylmethane diisocyanate MDI while stirring, then slowly raise the temperature, control the temperature at 80°C, and fill with nitrogen at the same time Protection, reaction for 2.5 hours. After sampling and analysis, the NCO% content reaches the design value of 2.5%, then add 11 parts of terpene resin, 2 parts of latent curing agent ALT-101, and 0.2 parts of catalyst triethylenediamine. Under the condition that the temperature is 100°C, vacuumize until no air bubbles appear, then discharge, and seal the package. Obtain the PUR glue of the present invention and place it for use.

Embodiment 2

[0030] Add 10 parts of polyether polyol PPG220 and 50 parts of polyester polyol XCP-3000H into the reaction kettle, vacuum dehydrate at 110°C for 2.5 hours, and keep the vacuum at -0.08MPa. Then cool to 80°C, add 8 parts of reactive plasticizer "Nikanol" resin and 13 parts of toluene diisocyanate TDI80 / 20 while stirring, then slowly raise the temperature, control the temperature at 70°C, and fill with nitrogen protection at the same time, react for 2.5 hours . After sampling and analysis, the NCO% content reaches the design value of 2.0%, then add 6 parts of petroleum tackifying resin, 3 parts of latent curing agent ALT-101, and 0.1 part of catalyst dibutyltin dilaurate. Under the condition that the temperature is 90° C., vacuumize until no air bubbles appear, and then discharge the material and seal the package. Obtain the PUR glue of the present invention and place it for use.

Embodiment 3

[0032] Add 30 parts of polyether polyol PPG204 and 30 parts of polyester polyol POL-356T into the reactor, vacuum dehydrate at 110°C for 3.5 hours, and keep the vacuum at -0.09MPa. Then cool to 80°C, add 18 parts of reactive plasticizer "Nikanol" resin and 16 parts of 4,4'diphenylmethane diisocyanate MDI while stirring, then slowly raise the temperature, control the temperature at 80°C, and fill with nitrogen at the same time Protection, reaction for 2.5 hours. After sampling and analysis, the NCO% content reaches the design value of 2.8%, then add 10 parts of terpene tackifying resin and 10 parts of petroleum tackifying resin, 1 part of latent curing agent ALT-101, 0.1 part of catalyst dibutyltin dilaurate and three 0.3 parts of ethylene diamine. Under the condition that the temperature is 110° C., vacuumize until no air bubbles appear, and then discharge the material and seal the package. Obtain the PUR glue of the present invention and place it for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com