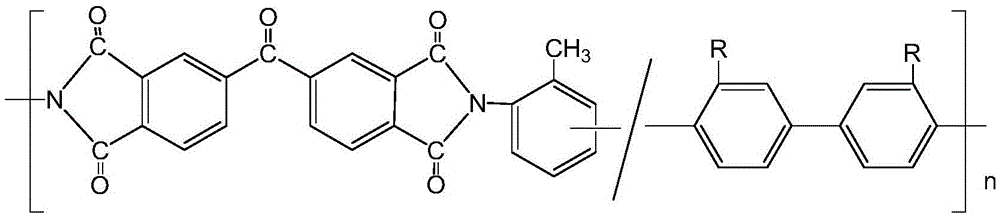

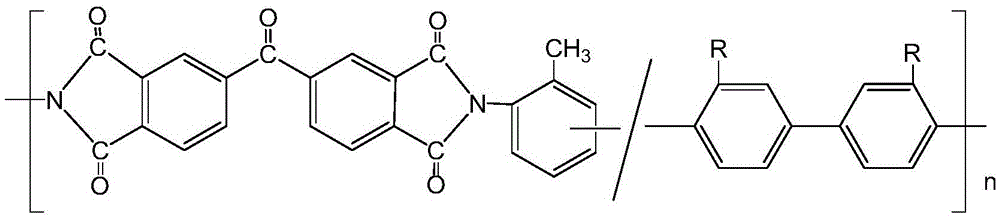

A kind of preparation method of ternary copolymerization polyimide fiber

A technology of ternary copolymerized polyimide fiber and dimethylacetamide, which is applied in the direction of fiber chemical characteristics, wet spinning method, single-component synthetic polymer rayon, etc., and can solve the problem of not being able to use for a long time, forming holes in the fiber, etc. problem, achieve the effect of avoiding decomposition or hydrolysis, low cost and mature process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] At the beginning of polymerization, it is first necessary to ensure that the humidity of the environment where the polymerization system is located is lower than 40%. Weigh 0.5mol (about 161g) of benzophenone tetraacid dianhydride (ketone anhydride) and 597g of N,N-dimethylacetamide (DMAc) into a 1000ml four-necked flask equipped with a stirring device and a nitrogen inlet , and then add 0.3 grams of NaOH solid solution (NaOH: water mass ratio = 1:1) as a catalyst, 60 grams of solubilizer (anhydrous LiCl or CaCl 2 ). Under the action of continuous stirring, heat the reaction system to 80°C, then add 0.5mol diisocyanate mixture (0.4mol toluene diisocyanate + 0.1mol biphenyl diisocyanate) dropwise into the reaction system, wait for the diisocyanate to drop After the addition is complete, continue the reaction until there is no CO 2 until the gas is generated. A viscous liquid with a solid content of about 30% and a reduced viscosity of 0.75 dL / g (measured at 30°C with ...

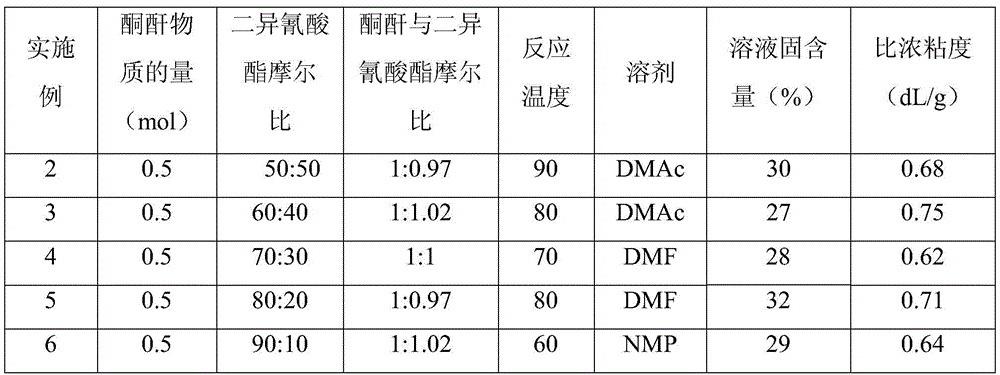

Embodiment 2-6

[0031] The reaction process is the same as in Example 1, and the other conditions are shown in Table 1.

[0032] Table 1: Polymerization conditions for Examples 2-6

[0033]

[0034] Note: The solvent DMAc in Table 1 is N,N-dimethylacetamide; DMF is N,N-dimethylformamide; NMP is N-methylpyrrolidone; the diisocyanate molar ratio is toluene diisocyanate to biphenyl The molar ratio of diisocyanate.

Embodiment 7

[0036] The polyimide solution obtained in Example 1 was spun and shaped by wet process technology. Fill the storage tank with spinneret with about 500ml of spinning slurry, and keep the temperature of the storage tank at 30-80°C by using the circulating water passing into the jacket, and the absolute vacuum degree is 1×10 -3 MPa~50×10 -3Stand for defoaming under MPa for 2 to 4 days, and then spinning can be carried out. The diameter of the spinneret hole is 0.08 mm, the aspect ratio (L / D) of the spinneret hole is 10, the temperature of the coagulation bath is 25 °C, and the composition of the coagulation bath is DMAc / water (70 / 30 mass ratio). The negative stretch of the nozzle is -30%, the water bath is tap water, the temperature is 70-90°C, and the draft ratio is 1.2. Nitrogen is used to apply a pressure of 0.3 MPa to 0.5 MPa to the spinning slurry, and the spinning slurry passes through a 1000-mesh filter cloth to obtain terpolymerized polyimide primary fibers. The as-spu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com