A kind of preparation method and application of functionalized tow for filter rod

A functionalized, tow technology, applied in spinning solution preparation, filament/thread forming, feeding solution to spinneret, etc., can solve problems such as reduced release, achieve good physical adsorption capacity and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

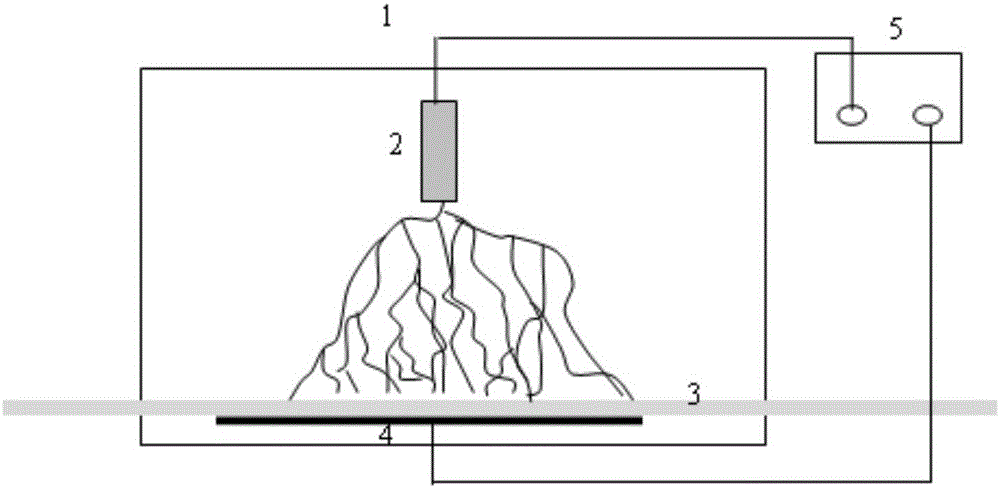

Method used

Image

Examples

Embodiment 1

[0025] The polyvinyl butyral (PVB) solution was spun separately. Polyvinyl butyral (PVB) was dissolved in ethanol to prepare a 10% (W / W) solution, which was placed in a storage tank and fed to 12 electrospinning nozzles by a micropump at a speed of 5 mL / h per pump. Supply the material liquid, the electrospinning voltage is 25KV, the distance between the nozzle and the paper base is 15cm, each group of electrospinning nozzles has 4 nozzles, and the continuous traveling acetate tow (speed 50m / min) is used as the substrate to receive online Polyvinyl butyral nanofibers, spray a layer of white nanofibers with a diameter of about 500nm on the cellulose acetate tow, and the mass ratio of the sprayed nanofiber film to the tow is 1:100. After online spraying and modification The acetate tow enters the plasticizer applicator and then undergoes filter rod forming. One end of the electrospinning chamber is continuously fed with air, and the other end discharges the air mixed with solven...

Embodiment 2

[0027] The cellulose acetate solution was spun separately. Dissolve cellulose acetate in acetone to prepare a 6% (V / V) solution, place it in a storage tank, and supply the material liquid to 8 electrospinning nozzles through a micropump at a speed of 3 mL / h for each pump. The spinning voltage is 20KV, the distance between the nozzle and the paper base is 18cm, and each group of electrospinning nozzles has 4 nozzles. On-line receiving cellulose acetate nanofibers based on the continuously advancing propylene fiber tow (speed 100m / min), spraying a layer of white nanofibers with a diameter of about 900nm on the propylene fiber tow, the sprayed nanofiber film and The mass ratio of tow is 1:300. The modified propylene fiber tow after online spraying enters the plasticizer application device and then performs filter rod molding. One end of the electrospinning room is continuously fed with air, and the other end discharges the air mixed with solvent from the electrospinning room fo...

Embodiment 3

[0029]Mixed spinning of polyethyleneimine and gelatin. Polyethyleneimine was dissolved in ethanol to prepare a 7% (V / V) solution, gelatin was dissolved in trifluoroethanol to prepare a 10% (V / V) solution, and the two solutions were mixed in a mass ratio of 60:40, Placed in the storage tank, the feed liquid is supplied to 8 electrospinning nozzles at a speed of 3mL / h through a micropump, the electrospinning voltage is 25KV, and the distance between the nozzle and the paper base is 15cm. Spin nozzle is 4 nozzles. The nanofibers of polyethylenimine and gelatin are received on-line with the continuously advancing propylene fiber tow (speed 80m / min), and a layer of white nanofibers with a diameter of about 3 μm is sprayed on the propylene fiber tow. The mass ratio of nanofiber membrane to tow is 1:200. The modified propylene fiber tow after online spraying enters the plasticizer application device and then performs filter rod molding. One end of the electrospinning chamber is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com