O-phthalaldehyde disinfectant and preparation method thereof

A technology of phthalaldehyde and disinfectant, which is applied in the direction of disinfectant, botany equipment and method, biocide, etc., can solve the problem that the normal physiological function of bacteria cannot be carried out, the signal of cell nutrient feeding cannot be obtained, and the dysfunction of material exchange, etc. problem, achieve good synergistic sterilization effect, shorten preparation time and save processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

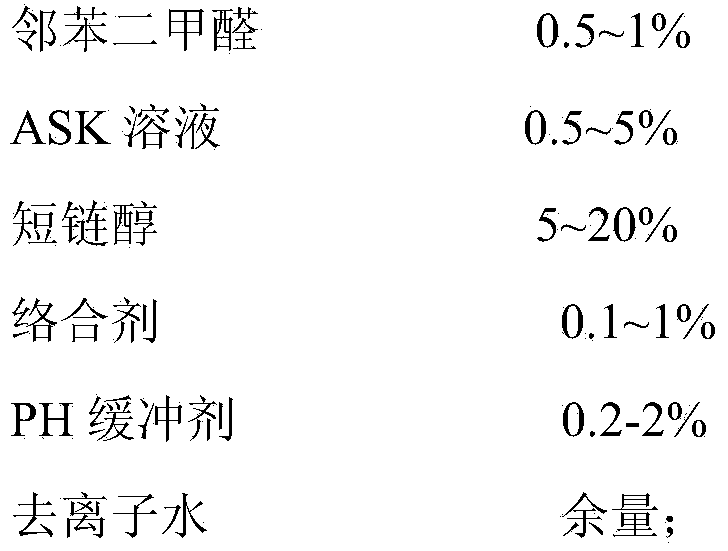

[0033] Composed of raw materials in the following weight percentages:

[0034]

[0035] The preparation method is:

[0036] (1) Add alkene-based fatty sulfonic anhydride (ASA) to 20% aqueous potassium hydroxide solution, react at 40°C for 3 hours, take the mixed solution in deionized water, if it can be completely dissolved, it means the reaction is complete, after the reaction is completed That is ASK solution;

[0037] (2) Dissolve o-phthalaldehyde in ethanol, stir to make it completely dissolved until clear; then add deionized water, mix well; then add coupling agent, complexing agent, after complete dissolution, add ASK solution and pH buffer Disinfectants (sodium dihydrogen phosphate and disodium hydrogen phosphate) until they are completely dissolved, and then filled after standing still. By adjusting the ratio of sodium dihydrogen phosphate and disodium hydrogen phosphate, the pH value of the prepared o-phthalaldehyde disinfectant is 8.5.

Embodiment 2

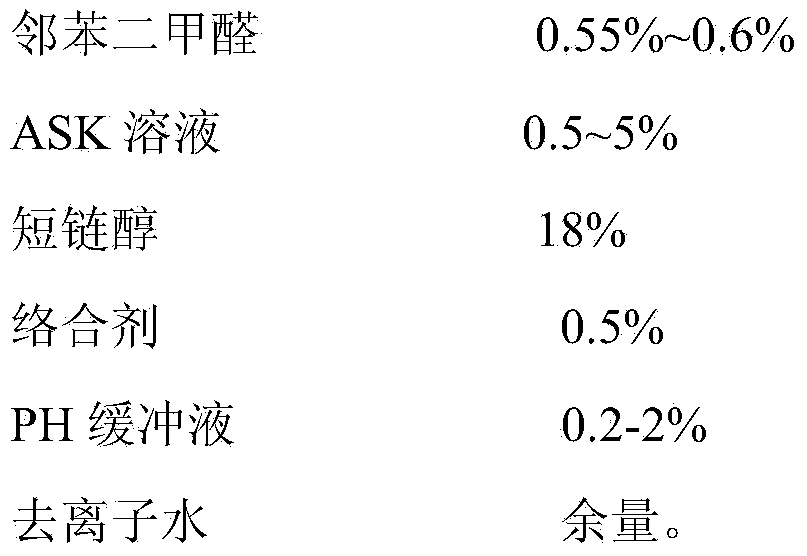

[0039] Consists of the following raw materials in parts by weight:

[0040]

[0041] The preparation method is:

[0042] (1) Add alkene-based fatty sulfonic anhydride (ASA) to triethanolamine, react at 10°C for 4 hours, take its mixed solution in deionized water, if it can be completely dissolved, it means that the reaction is complete, and the ASK solution is obtained after the reaction is completed;

[0043] (2) Dissolve o-phthalaldehyde in ethanol, stir to make it completely dissolved until clear; then add deionized water, mix well; then add coupling agent, complexing agent, after complete dissolution, add ASK solution and pH buffer Disinfectant (sodium dihydrogen phosphate and disodium hydrogen phosphate) until it is completely dissolved, and filled after standing still. By adjusting the ratio of sodium dihydrogen phosphate and disodium hydrogen phosphate, the pH value of the prepared o-phthalaldehyde disinfectant is 9.0.

Embodiment 3

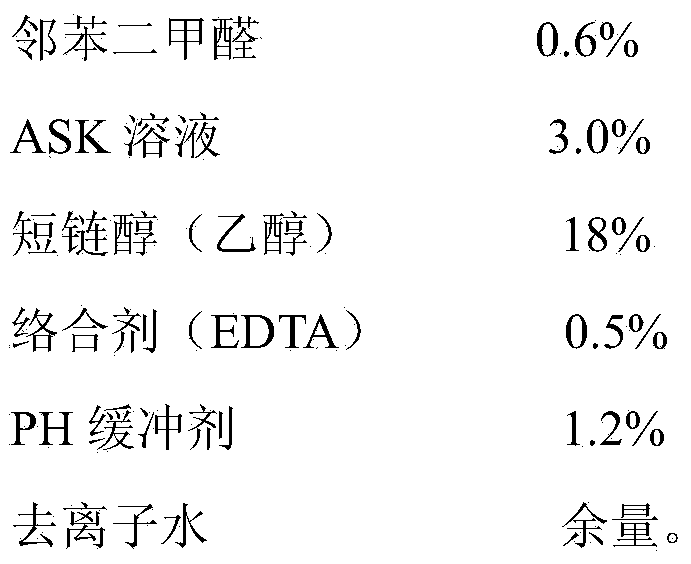

[0045] Consists of the following raw materials in parts by weight:

[0046]

[0047] The preparation method is:

[0048] (1) Add alkenyl fatty sulfonic anhydride (ASA) into 15% potassium hydroxide aqueous solution, react at 45°C for 2 hours, take the mixed solution in deionized water, and if it can be completely dissolved, it means the reaction is complete. Obtain ASK solution;

[0049](2) Dissolve o-phthalaldehyde in ethanol, stir to make it completely dissolved until clear; then add deionized water, mix well; then add coupling agent, complexing agent, after complete dissolution, add ASK solution and pH buffer Disinfectants (sodium dihydrogen phosphate and disodium hydrogen phosphate) until they are completely dissolved, and filled after standing still. By adjusting the ratio of sodium dihydrogen phosphate and disodium hydrogen phosphate, the pH value of the prepared o-phthalaldehyde disinfectant is 7.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com