Method for manufacturing printed circuit board by power triggering electroless plating addition process

A printed circuit board, electroless plating technology, applied in printed circuit, printed circuit manufacturing, liquid electroless plating, etc., can solve the problems of limited thickness of electroless plating, expensive inkjet printing equipment, easy failure of catalysts, etc., to control process parameters Less, easy to operate, and the effect of fast plating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

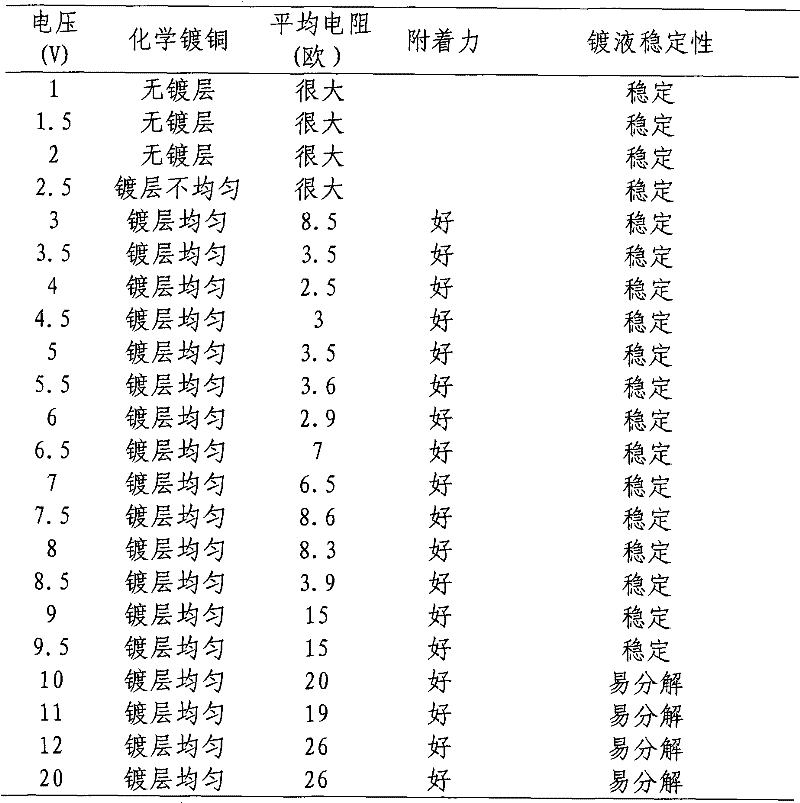

[0027] The present invention takes polyester film as an example to print carbon paste patterns on the screen and electroless copper plating on the carbon paste patterns to illustrate the manufacturing process of PCB circuit patterns in detail.

[0028] Table 1 Formula of electroless copper plating solution

[0029] Chemical reagent Concentration g / L

[0030] CuSO 4 ·5H 2 O 16

[0031] Sodium Potassium Tartrate 14

[0032] Disodium edetate 19.5

[0035] HCHO (formaldehyde) 15ml / L

[0036] pH 12~12.5

[0037] Temperature ℃ 40~50

[0038] The specific experimental steps are as follows:

[0039] (1) make a 15cm * 15cm * 10cm with plexiglass, the cuboid without top is used as the chemical plating tank body;

[0040] (2) Graphite is used as the anode material, connected to the positive pole of the power supply, and the pure copper sheet is used as the cathode, connected to the negative pole...

Embodiment 2

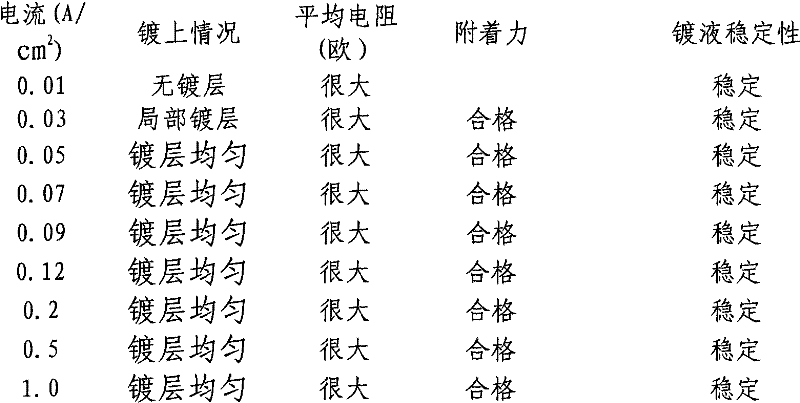

[0050] The invention takes the electroless nickel plating of the polyester film with the carbon paste pattern printed on the screen as an example, and specifically illustrates the PCB circuit pattern manufacturing process.

[0051] Table 3 Formula of electroless nickel plating solution

[0052] Chemical reagent Concentration g / L

[0053] NiSO 4 ·6H 2 O 25

[0054] Citric acid 6

[0055] Sodium succinate 5

[0056] Ammonium acetate 4.5

[0057] Glycine 1

[0058] Lactic acid 8ml / L

[0059] NaH 2 PO 2 ·H 2 O 25

[0060] pH 4.8~5.2

[0061] Temperature ℃ 80~85

[0062] The specific experimental steps are as follows:

[0063] 1. Use plexiglass to make a 15cmX15cmX10cm, cuboid without a roof as the chemical plating tank;

[0064] 2. Use graphite as the anode material, connect to the positive pole of the power supply, iron sheet as the cathode, and connect to the negative pole of the power supply;

[0065] 3. Add the electroless copper plating solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com