Preparation method of disinfectant perglutaric acid

A peroxyglutaric acid and disinfectant technology, which is applied in the field of preparation of disinfectant peroxyglutaric acid, can solve the problems of low peroxyglutaric acid content, inconvenient transportation and storage, and unsatisfactory stability, and achieve the goal of making Simple process, no irritating smell, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a technical scheme: a preparation method of disinfectant peroxyglutaric acid, comprising the following mass components;

[0022] 21-31 parts of sodium percarbonate, 15-22 parts of urea peroxide, purified water, 40-60 parts of glutaric acid, 1,3-propylene glycol, and 0.01-0.05 parts of sodium nitrite.

[0023] Preferably, the sodium percarbonate is alkaline when dissolved in an aqueous solution, and the urea peroxide is acidic when dissolved in water, and the pH value of the solution fluctuates within the range of 6-8 by rationally adjusting the ratio of the two in the system.

[0024] Preferably, the conductivity of the purified water should be 5us / cm-45us / cm, and the addition amount is 10%-15%.

[0025] Preferably, the 1,3-propanediol is used as a stabilizer for peroxyglutaric acid, and the addition amount is 0.001%-0.05%.

[0026] Preferably, the sodium nitrite is a corrosion inhibitor.

[0027] A preparation method of disinfectant perglutaric...

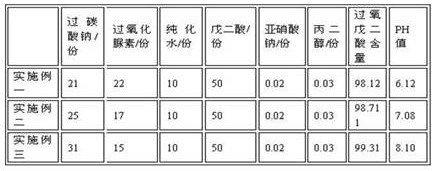

example 1

[0032] A preparation method of disinfectant perglutaric acid, comprising the following quality components;

[0033] Sodium percarbonate 21, urea peroxide 22, purified water 10, glutaric acid 50, sodium nitrite 0.02, propylene glycol 0.03, through the above combination formula, the content of peroxyglutaric acid is 98.12%.

[0034] Preferably, the sodium percarbonate is alkaline when dissolved in an aqueous solution, and the urea peroxide is acidic when dissolved in water, and the pH value of the solution is 6.12 by rationally adjusting the ratio of the two in the system.

[0035] Preferably, the sodium nitrite is a corrosion inhibitor.

[0036] A preparation method of disinfectant perglutaric acid, comprising the following steps;

[0037] Step 1. Treat the purified water with a bipolar reverse osmosis water treatment system to make its conductivity meet the specified requirements, and add sodium percarbonate and urea peroxide to completely dissolve it;

[0038] Step 2. Add g...

example 2

[0041] A preparation method of disinfectant perglutaric acid, comprising the following quality components;

[0042] Sodium percarbonate 25, urea peroxide 17, purified water 10, glutaric acid 50, sodium nitrite 0.02, propylene glycol 0.03, through the above combination formula, the content of peroxyglutaric acid is 98.711%.

[0043] Preferably, the sodium percarbonate is alkaline when dissolved in an aqueous solution, and the urea peroxide is acidic when dissolved in water, and the pH value of the solution is 7.08 by rationally adjusting the ratio of the two in the system.

[0044] Preferably, the sodium nitrite is a corrosion inhibitor.

[0045] A preparation method of disinfectant perglutaric acid, comprising the following steps;

[0046] Step 1. Treat the purified water with a bipolar reverse osmosis water treatment system to make its conductivity meet the specified requirements, and add sodium percarbonate and urea peroxide to completely dissolve it;

[0047] Step 2. Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com