Sea mollusc fungicide

A mollusk and fungicide technology, applied in the directions of fungicides, animal repellents, biocides, etc., can solve the problems of large equipment maintenance, easy leakage, strong irritating odor of chlorine gas, etc., to achieve no environmental pollution, easy Unique effect of degradation and sterilization mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

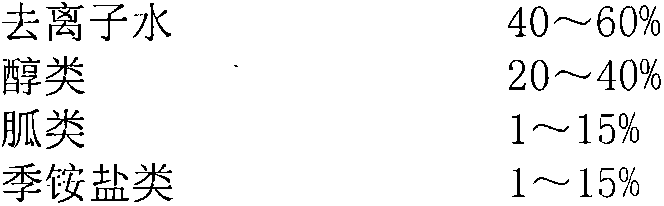

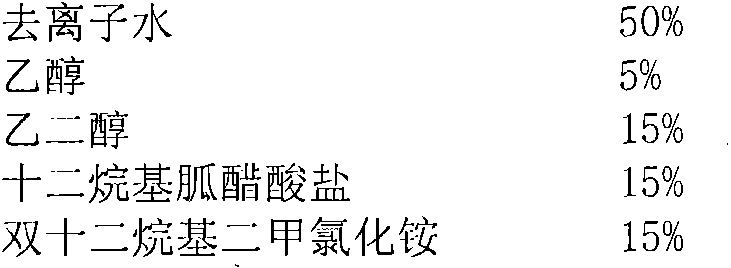

[0019] Select raw materials by weight percentage

[0020]

[0021] Specific production methods:

[0022] Add 20% of deionized water, 5% of ethanol, 15% of ethylene glycol, and 15% of dodecylguanidine acetate into the reactor, keep the temperature at 25 to 35°C, stir for 60 minutes, and then add the didodecane. An aqueous solution of 15% dimethyl ammonium chloride and 30% deionized water was added to the reaction kettle by a metering pump, the addition time was 20 to 40 minutes, and the product was obtained by continuing to stir for 30 minutes.

Embodiment 2

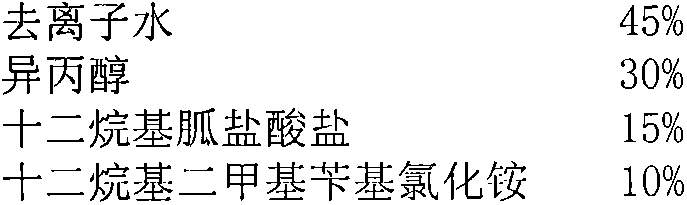

[0024] Select raw materials by weight percentage

[0025]

[0026] Specific production methods:

[0027] Add 25% of deionized water, 30% of isopropanol, and 15% of dodecylguanidine hydrochloride into the reactor, keep the temperature at 25-35°C, stir for 60 minutes, and then add dodecyldimethylbenzyl The aqueous solution of 10% ammonium chloride and 20% deionized water was added to the reaction kettle with a metering pump, the addition time was 20-40 minutes, and the stirring was continued for 30 minutes.

Embodiment 3

[0029] Select raw materials by weight percentage

[0030]

[0031] Specific production methods:

[0032] Add 30% deionized water, 5% ethanol, 25% ethylene glycol, 10% isopropanol, and 15% dodecylguanidine hydrochloride into the reactor, keep the temperature at 25-35°C, and stir for 60 minutes. Then, an aqueous solution of 5% dodecyldimethylbenzyl ammonium chloride and 10% deionized water was added to the reaction kettle with a metering pump, the addition time was 20-40 minutes, and the stirring was continued for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com