Special thermal insulation glass fiber composite material for aviation and preparation method thereof

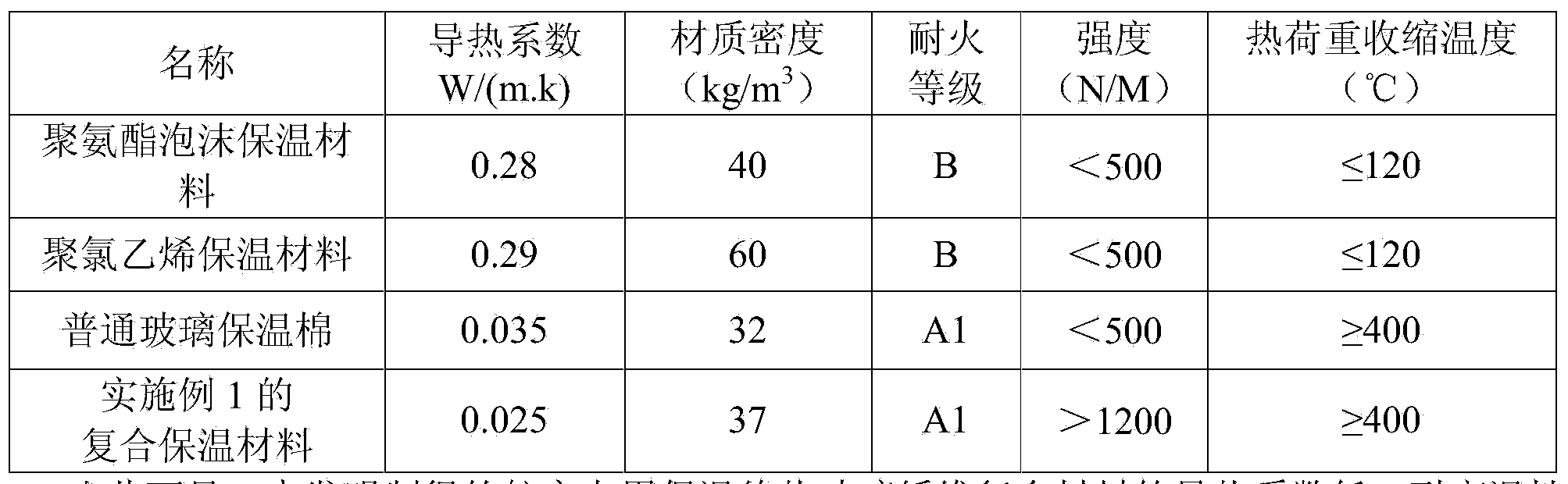

A composite material and glass fiber technology, which is applied in the field of special thermal insulation glass fiber composite materials for aviation and its preparation, can solve the problems of inability to meet the use requirements, poor installation and processing performance, low strength of thermal insulation materials, etc., and achieves small pores and reduces radiation. , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The method of the present invention for preparing aviation-specific thermal insulation glass fiber composite material comprises the following steps:

[0035] 1) Raw material preparation: select 4 parts of zinc oxide, 22 parts of borax, 29 parts of white sand, 29 parts of potassium feldspar powder, 6 parts of soda ash, 4.6 parts of calcite, 0.8 parts of potassium carbonate, 4.6 parts of barium carbonate, and mix well;

[0036] 2) Melting: Melt the raw materials in step 1) into molten glass in a nickel-chromium crucible with a leak;

[0037] 3) Primary fiberization: After the glass liquid in step 2) flows out from the leakage hole, the primary fiber is obtained by manual wire drawing and arranging;

[0038] 4) Secondary fiberization: the primary fiber in step 3) is drawn by high-temperature and high-speed airflow to produce glass fiber cotton with a diameter of 1.25 μm;

[0039] 5) Forming: Send the glass fiber cotton obtained in step 4) into the airflow forming machine,...

Embodiment 2

[0048] The method of the present invention for preparing aviation-specific thermal insulation glass fiber composite material comprises the following steps:

[0049] 1) Preparation of raw materials: select 3 parts of zinc oxide, 22 parts of borax, 30 parts of white sand, 29.5 parts of potassium feldspar powder, 5 parts of soda ash, 4.6 parts of calcite, 0.9 parts of potassium carbonate, and 5 parts of barium carbonate, and mix them evenly;

[0050] 2) Melting: Melt the raw materials in step 1) into molten glass in a nickel-chromium crucible with a leak;

[0051] 3) Primary fiberization: After the glass liquid in step 2) flows out from the leakage hole, the primary fiber is obtained by manual drawing and wire arrangement;

[0052] 4) Secondary fiberization: the primary fiber in step 3) is pulled by high temperature and high speed airflow to produce glass fiber cotton with a diameter of 0.75 μm;

[0053] 5) Forming: Send the glass fiber cotton obtained in step 4) into the airflo...

Embodiment 3

[0062] The method of the present invention for preparing aviation-specific thermal insulation glass fiber composite material comprises the following steps:

[0063] 1) Raw material preparation: select 5 parts of zinc oxide, 22 parts of borax, 29 parts of white sand, 30 parts of potassium feldspar powder, 5 parts of soda ash, 3.6 parts of calcite, 0.9 parts of potassium carbonate, 4.5 parts of barium carbonate, and mix well;

[0064] 2) Melting: Melt the raw materials in step 1) into molten glass in a nickel-chromium crucible with a leak;

[0065] 3) Primary fiberization: After the glass liquid in step 2) flows out from the leakage hole, the primary fiber is obtained by manual wire drawing and arranging;

[0066] 4) Secondary fiberization: use high-temperature, high-speed airflow to pull the primary fiber in step 3) to produce glass fiber cotton with a diameter of 1.0 μm;

[0067] 5) Forming: Send the glass fiber cotton obtained in step 4) into the airflow forming machine, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com