Method for synthesizing polymer particles with multilayer shell structure by semicontinuous emulsion polymerization

A technology of structural polymer and emulsion polymerization, applied in the field of polymer chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

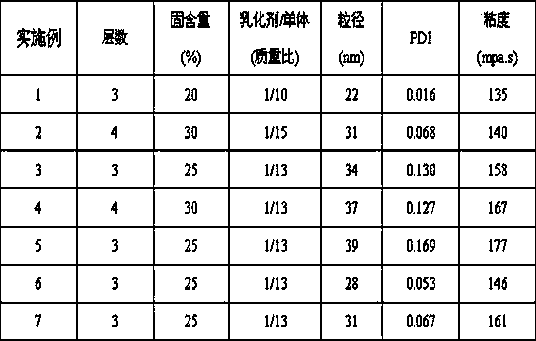

Examples

Embodiment 1

[0028] 1: Preparation of polymer particle core with shell structure

[0029] Add 2.0gSDS to 0.1gNaHCO 3 , 80g of deionized water in a solution. Repeatedly pass nitrogen to remove oxygen in the system, stir the solution to 65°C and add 0.3g of APS initiator, raise the temperature to 80°C at a constant temperature, slowly and continuously drop 10g of styrene (St) into the system at a rate of 0.16g / min Add dropwise at a speed of 1 h, maintain a nitrogen atmosphere, and stir at a low speed. After the dropwise addition, continue to react at 80° C. for 2 h to complete the monomer reaction.

[0030] Two: Preparation of the middle layer of polymer particles with shell structure

[0031] Slowly and continuously drop 5g of methyl methacrylate (MMA) monomer into the system, maintain the conditions of 80°C and nitrogen atmosphere, stir at a low speed, add dropwise at a speed of 0.08g / min for 1h, continue to react at 80°C after the dropwise addition is completed 1h, to complete the mon...

Embodiment 2

[0037] 1: Preparation of polymer particle core with shell structure

[0038] Add 2.0gSDS to 0.1gNaHCO 3 , 80g of deionized water in a solution. Repeatedly pass nitrogen to remove oxygen in the system, stir the solution to 65°C and add 0.3g KPS initiator, raise the temperature to 80°C at a constant temperature, slowly and continuously drop 15g of styrene (St) into the system at a rate of 0.25g / min Add dropwise at a speed of 1 h, maintain a nitrogen atmosphere, and stir at a low speed. After the dropwise addition, the reaction was continued at 80°C for 2 h to complete the monomer reaction.

[0039] Two: Preparation of the middle layer of polymer particles with shell structure

[0040] Slowly and continuously drop 5g of methyl methacrylate (MMA) monomer into the system, maintain the conditions of 80°C and nitrogen atmosphere, stir at a low speed, add dropwise at a speed of 0.08g / min for 1h, continue to react at 80°C after the dropwise addition is completed 1h, to complete the...

Embodiment 3

[0048] 1: Preparation of polymer particle core with shell structure

[0049] Add 2.0gSDS / OP-10 compound emulsifier (SDS / OP-10=2:1, mass ratio, the same below) to 0.1gNaHCO 3 , 80g of deionized water in a solution. Repeatedly pass nitrogen to remove oxygen in the system, stir the initiator solution to 65°C and add 0.3g of KPS initiator, raise the temperature to 80°C at a constant temperature, slowly and continuously drop 10g of styrene (St) into the system at a rate of 0.16g / Add dropwise at a speed of min for 1 h, maintain a nitrogen atmosphere, and stir at a low speed. After the dropwise addition, continue to react at 80° C. for 2 h to complete the monomer reaction.

[0050] Two: Preparation of the middle layer of polymer particles with shell structure

[0051] Slowly and continuously drop 10g of methyl methacrylate (MMA) monomer into the system, maintain the conditions of 80°C and nitrogen atmosphere, stir at a low speed, add dropwise at a speed of 0.16g / min for 1h, and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com