Method for grafting polycaprolactone onto hemicellulose in polar aprotic solvent system

A polar aprotic and hemicellulose technology, which is applied in the field of high-value utilization of biomass, can solve the problems of variable structure, solubility and reactivity changes, complex hemicellulose composition, etc., and achieve strong solubility and improved The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The hemicellulose grafted polycaprolactone of the present embodiment is in DMSO / LiCl, and its specific process is as follows:

[0025] Step 1. Hemicellulose (xylan content 85%) was vacuum dried at 50°C for 12h; the hemicellulose was dispersed in DMSO / LiCl (LiCl mass percentage 6%) and stirred at 80°C under nitrogen protection 2h, obtain hemicellulose solution;

[0026] Step 2. Slowly add caprolactone monomer dropwise according to the ratio of caprolactone monomer to hemicellulose mass ratio of 18:1, and react at 100°C for 24h;

[0027] Step 3. After the reaction solution is cooled to room temperature, add ethanol to precipitate (150ml*3 times), filter and add 150ml of dichloromethane to the precipitate, stir magnetically for 72h, filter, and dry under reduced pressure at 50°C and vacuum degree of 0.1MPa for 48h , to obtain the final product hemicellulose grafted polycaprolactone.

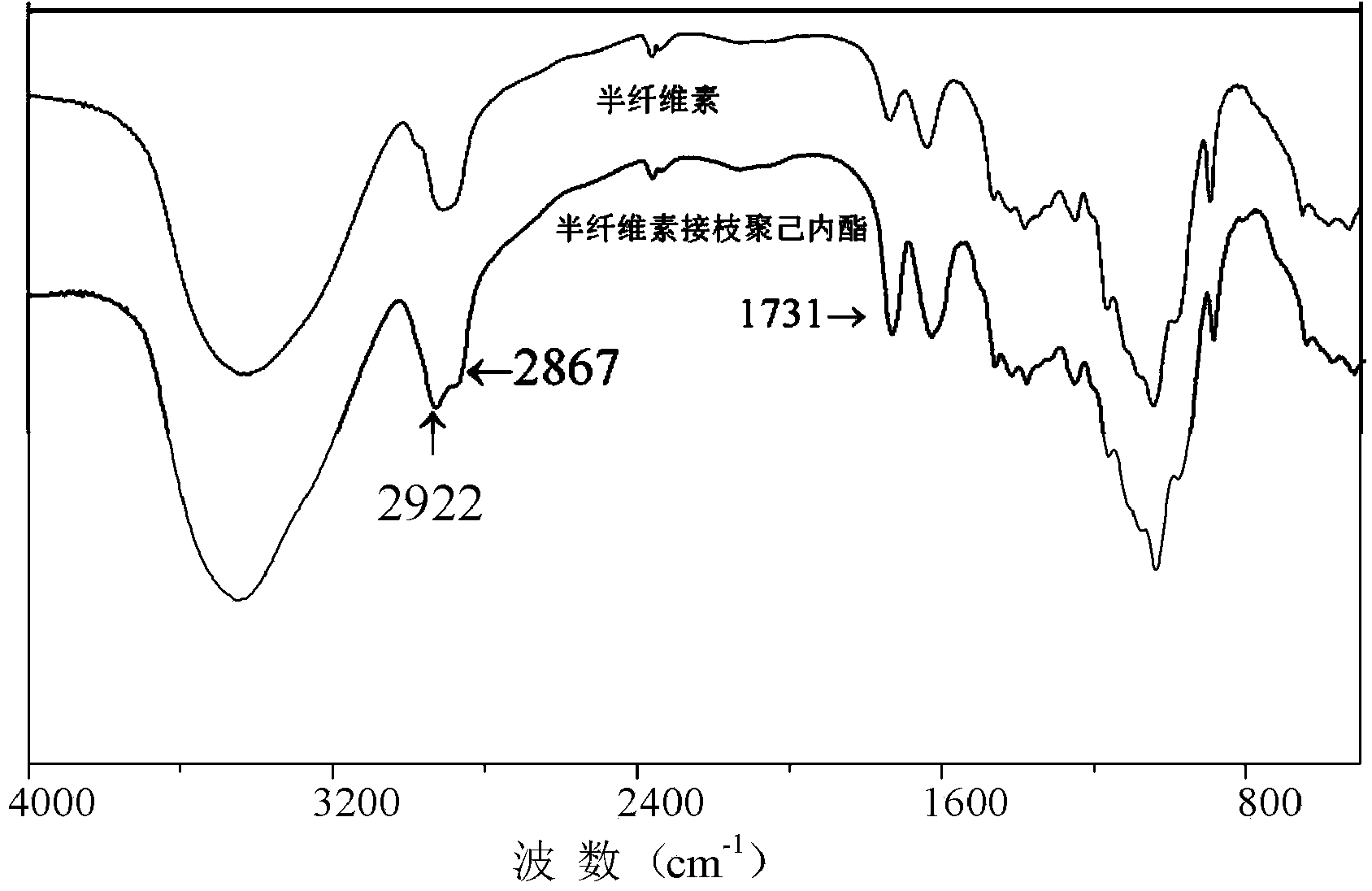

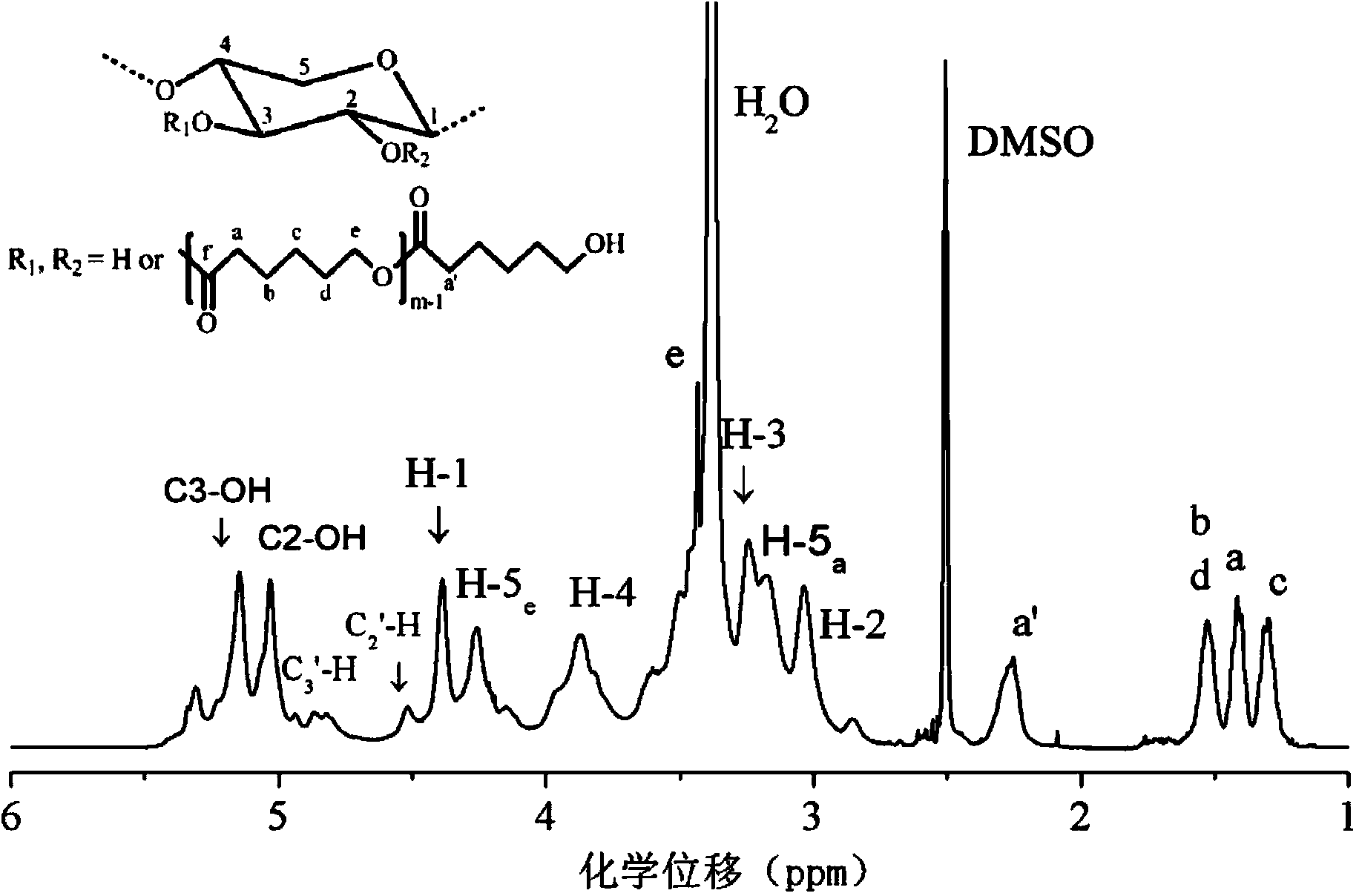

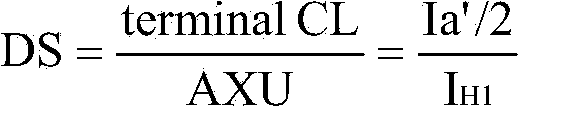

[0028] Infrared and hydrogen spectra of unmodified hemicellulose and hemicellulose graf...

Embodiment 2

[0036] The hemicellulose grafted polycaprolactone of the present embodiment is in DMAc / LiCl, and its specific process is as follows:

[0037] Step 1. Hemicellulose (55% xylan content) was vacuum-dried at 50°C for 12 hours; the hemicellulose was dispersed in DMAc / LiCl (0.1% LiCl by mass), stirred at 150°C under nitrogen protection 24h, obtain hemicellulose solution;

[0038] Step 2. Slowly add caprolactone monomer dropwise according to the ratio of caprolactone monomer to hemicellulose mass ratio of 52:1, and react at 30°C for 0.5h;

[0039] Step 3. After the reaction liquid is cooled to room temperature, add ethanol to precipitate (150ml*3 times), filter and add 150ml of dichloromethane to the precipitate, magnetically stir for 72h, filter, and freeze-dry at -40°C for 36h to obtain the final product Hemicellulose grafted polycaprolactone. The infrared spectrum of the prepared hemicellulose grafted polycaprolactone and figure 1 Similarly, the hydrogen spectrum is similar to ...

Embodiment 3

[0041] The hemicellulose grafted polycaprolactone of the present embodiment is in DMF / LiCl, and its specific process is as follows:

[0042] Step 1. Hemicellulose (65% xylan content) was vacuum-dried at 50°C for 12 hours; the hemicellulose was dispersed in DMF / LiCl (15% LiCl by mass), stirred at 30°C under nitrogen protection 0.1h, obtain hemicellulose solution;

[0043] Step 2. Slowly add caprolactone monomer dropwise according to the ratio of caprolactone monomer to hemicellulose mass ratio of 0.5:1, and react at 150° C. for 16 hours;

[0044] Step 3. After the reaction solution is cooled to room temperature, add ethanol to precipitate (150ml*3 times), filter and add 150ml of dichloromethane to the precipitate, stir magnetically for 72h, filter, and dry under reduced pressure at 20°C and vacuum 0.1MPa for 48h , to obtain the final product hemicellulose grafted polycaprolactone.

[0045] The infrared spectrum of the prepared hemicellulose grafted polycaprolactone and figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com